-2-

A. Description

1. Function

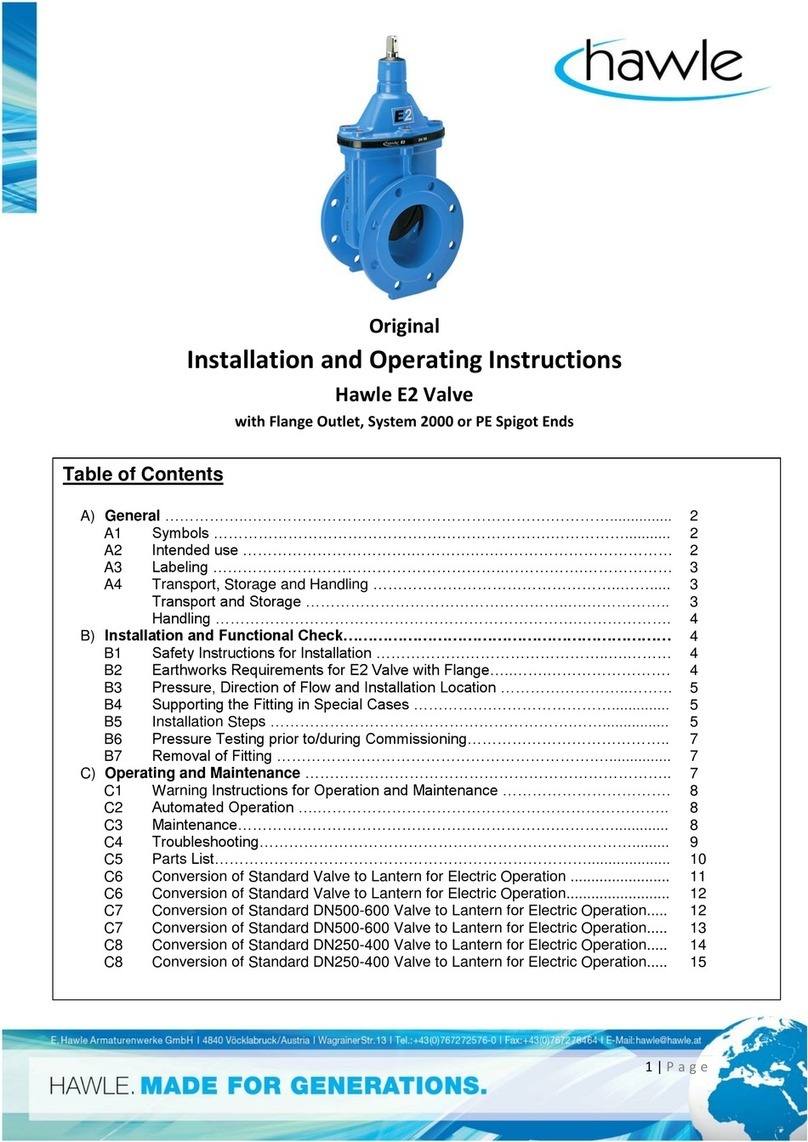

The HAWIDO 1703 and HAWIDO 1704 are valve units with an electrical solenoid valve. The filling or

emptying of the control chamber of the main valve (1) are controlled by the electrical solenoid valve (5). The

pressure of its own medium therefore closes or opens the valve. Depending on the electrical solenoid valve

type (5), the valve can be positively or negatively controlled, i.e. the main valve (1) is normally-closed and

opens under voltage (HAWIDO 1703), or it is normally open and closes when under voltage (HAWIDO

1704).

The closing speed can be adjusted using the one-way flow restrictor (4).

Technical features:

Medium: Drinking water

Pressure stages: PN 10 (from DN 200 Standard)

PN16 (up to DN150 Standard)

PN25

Flanges: Connection dimensions according to DIN 1092 -2

Pressure gauge: EN 837-1; Accuracy class 1.6

Main valve material: EN-GJS-400-15

Temperature range: 2 –40 °C

2. General safety instructions

These instructions must be read through carefully and understood before starting the commissioning.

Damage to property and injuries to persons could occur as a result of improper installation, commissioning,

operation and maintenance.

The Hawle regulating valve (HAWIDO) has been designed for use in drinking and process water supplies.

Other application media only after consultation with the manufacturer.

The technical regulations (e.g. SVGW, ÖVGW, DVGW...) and codes of practice (e.g. VDE, VDI ...), laws and

standards are taken as a minimum standard, and must be adhered to and applied.

Work on electrical installations (e.g. installation of magnetic position switches, solenoid valves, etc.) may only

be carried out by personnel authorised for this work.

In principle, the responsibility for the layout, the installation position, the installation and the commissioning of

the fittings in the pipe work lies with the designer, the installation company and/or the operator. Design or

installation errors can adversely affect the safe operation of the regulating valve, and can represent a

significant risk. Please consult us in case of doubt.