Agilis Jettenders 330 User guide

Owner‘s Handbook

Agilis Jet Tenders

Lohfeldstr. 2

D-52428 Jülich

GERMANY

ofce: (+49) 2461 - 340 33 30

fax: (+49) 2461 - 340 33 313

www.agilis-jettenders.com

305 - 330

Welcome to Agilis Jettenders!

Welcome to Agilis Jettenders! And thank you for choosing our product!

We have conceived this handbook to give you enough information while at sea. This way we are

sure you will enjoy your ride safely.

The content of this handbook will inform you about the equipment, its operation and maintenance.

It is very important that you read it and familiarise yourself with the boat.

Please note that this jet uses water jet propulsion. Be aware that maneuverability decreases while

decelarating. Handling and operating experience, as well as knowledge of seamanship is

compulsory (please refer to RYA Level 2 or ICC).

At delivery, your Agilis authorized dealer will guide you through the functions and features of the

boat. Do not forget to ll your warranty registration form with the boat‘s CIN. This handbook should

be kept in a secure place and handed over to the next owner.

Your safety is our priority. Therefore we ask you to comply with the safety information provided in

this handbook. Always obey the safety labels tted. Should they become unreadable, we expect

that you replace them. Local laws and restrictions are to be applied. Be aware that the inuence of

drugs and alcohol may affect your judgement.

This symbol appears on a number of labels tted to the tender.

It draws your attention to the message and refers you to the owner‘s handbook.

This safety alert symbol appears throughout the handbook and on various labels

tted to the tender. It means attention, be vigilant, your safety is involved!

Danger: situation that can result in death or serious injury.

Warning: situation that can result in death or serious injury.

Caution: situation that can result in minor or moderate injury.

To avoid personal injuries always secure loose equipment safely. Make sure that equipment

close to machineries are secured in a way that they do not fall into the engines.

Be aware of the environment. In many regions of the world, there are strictly enforced

regulations regarding the protection of the environment. It is the responsibility of the owner/

operator to be aware of applicable regulations and to comply with them.

Craft Identification Number (CIN):

INTRODUCTION

Table of Content

1. Introduction

2.General Data

2.1 Engine

2.2Classication

3. Hazards & Safety

3.1Riskofooding&stability

3.2Riskofreorexplosion

3.3ElectricalSystem-Riskofre,explosionorelectricshocks

4. Operating your tender

4.1 New Engine Break-In Period

4.2 Steering Systems

4.3 Fuelling

4.4 Check List

4.5 Accelaration & Brakes

4.6 Anchoring, mooring, towing and lifting

4.7 After use: Flushing procedure

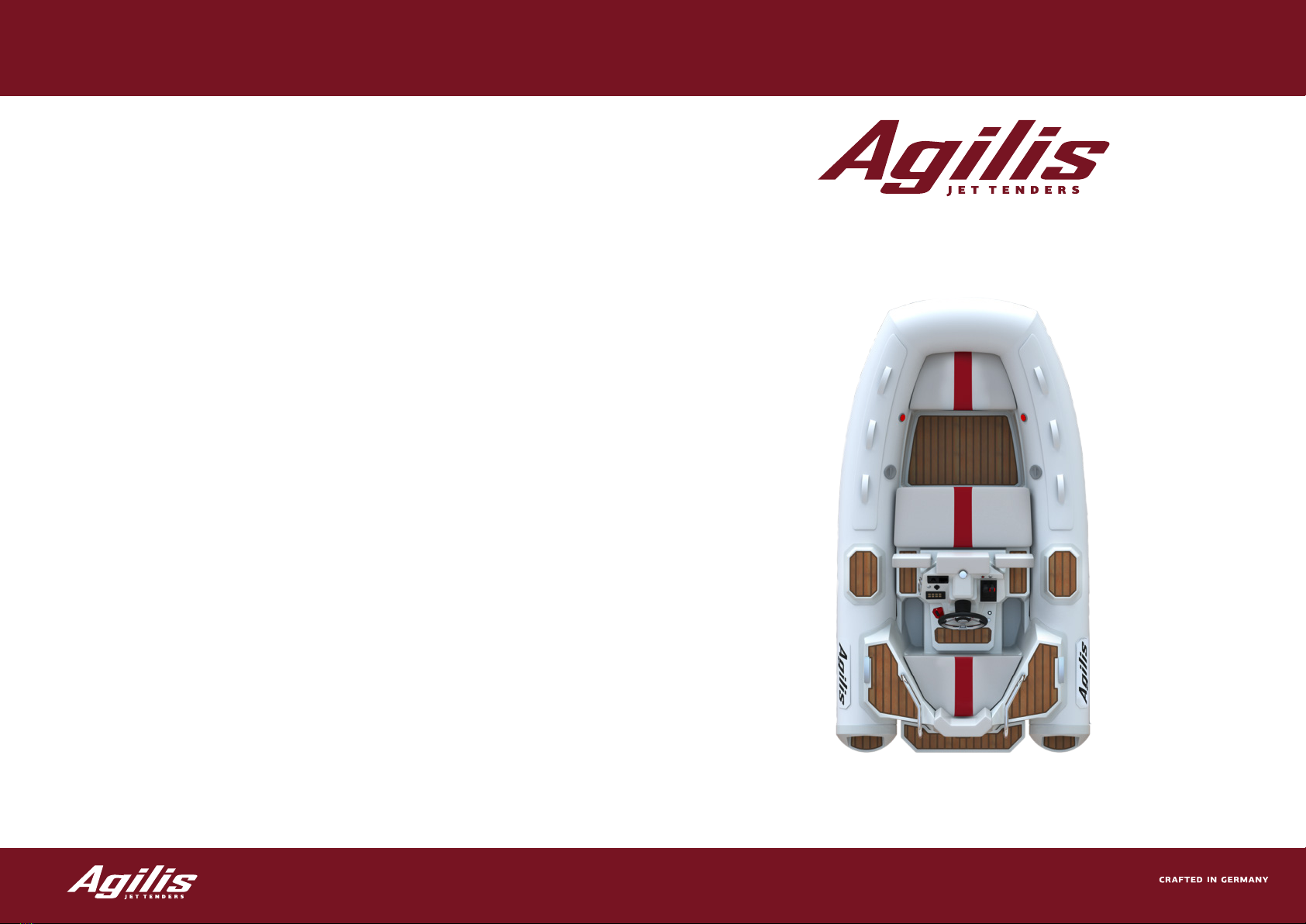

5. General Layout

5.1 Overview

5.2 Engine Compartment

5.3FuseIdentication

5.4 Full Inspection Maintenance Table

6. Winter Storage

7. Warranty

General Data

Model

LOA

Beam

Dry Weight without options

Height

Max Speed at full load

Power

Fuel Capacity

Seating

Max Load Capacity

Design Category

305

3,05 m

1,75 m

288 kg

0,86 m

69 km/h

42 Liters

4

328 kg

C

330

3,30 m

67,1 kw / 90 hp

1,75 m

315 kg

0,86 m

68 km/h

67,1 kw / 90 hp

4

55 Liters

340 kg

C

GENERAL DATA

Engine

Engine ROTAX 900 HO ACE

Maximum

Power

Fuel

Oil Grade

Oil Capacity

Naturally aspirated 66,2 kW / 90 HP

Recommended fuel quality: Unleaded gasoline with an octane rating of at least 95 R OZ or 85 MOZ.

USA: At least “Premium 91”, unleaded

Minimum requirement: Low-quality fuel can cause loss of power and/or increase fuel consumption

Unleaded gasoline with an octane rating of at least 91 ROZ or 82.5 MOZ.

USA: At least “Regular 87”, unleaded

An increased share of ethanol can lead to premature abrasion or poor starting performance of the engine.

Use XPS 4-STROKE SYNTH. BLEND OIL

(SUMMER) (P/N 460787)

maximum 1.8 liters

Classication

Category C - „inshore“: Craft designed for trips in coastal waters, large bays, estuaries, lakes and rivers. Wind

force6andsignicantwaveheightsupto2mmaybeexperienced.

This boat complies with ISO 6185-3.

The CE plate is located in the starboard rear foot well.

TheCEplateisthecerticationtoEuropeanDirective2013/53/EU.

Technical Specications

Hazards & Safety

Risk of ooding and stability

1. Openings in the hull. (see General Layout)

2. Bilge pump.

Amanuallyoperatedbilgepumpistted.

For operating instructions see owner‘s manual of the bilge pump.

Theaudioalarmontheinstrumentpanelsignalsifbilgelevelexceeds50mm.Inthiscase:

1. Switch off the engine.

2. Open the hood to check for water.

3. Checkforoil.Inthewatercontainsoil,ONLYREMOVEMANUALLY.

4. If water is free from environmentally hazardous substances, then activate the

pump.

CAUTION Check the function of bilge pump at regular intervals.

Clear debris from the pump inlets.

WARNING: This system is not suitable for a complete draining in case of

damage.

3. Stability and buoyancy.

3.1 Position of persons and luggage.

For safe operation we recommend that your passengers sit in the middle of the boat.

Thelocationofthepassengerswilldirectlyinuencethestabilityofthiscraft.

Sitting on the sides of the boat is ALSO ACCEPTABLE as long as there is someone

sitting on the opposite side.

CAUTION While you are sailing at high speed avoid abrupt turns and

high waves as this might endanger the passengers. Make sure everybody

holds on to the safety ropes. For comfort and safety, reduce speed in waves.

Small children must sit IN the boat. Always wear a lifejacket!

When taking a sharp turn, reduce the speed of your boat. The boat will tilt

considerably inside the turning centre.

3.2 Bilge water should be kept to a minimum

3.3 Stability is reduced by any weight added

3.4 Stability may be reduced when towing

3.5 Breaking waves is a serious stability hazard

Risk of re or explosion

WARNING: Riskofre.Donotstorefuel,tanksfuellinesoranyfuel-relatedcomponentsin

direct sunlight.

1. ENGINE

Instructions for safe operation of the engine:

a) run the engine compartment fan for 5 minutes before switching on / after switching

off the engine

b) ensureowofcoolingwater

c) ensure that ventilation ducts are free

d) no smoking when refuelling and treatment of fuel spillage in craft

e) check for possible damage of fuel lines

f) avoidcontactofammablematerialswithhotengineparts

g) do not store equipment containing petrol in compartments not designed for this

purpose.

2. FIRE-FIGHTINGEQUIPMENT

2.1 FIREEXTINGUISHER

Anautomaticreextinguisheristtedintheenginecompartmentonstarboardside.

The1Kgcapacityofthereextinguishercanprotectanenginecompartmentupto1,7.Theprotec-

ted space of the boat is 1,25 .

The red light on the pilot desk blinks when:

1. thereisnotenoughpressureinthere-extinguisher.

2. there-extinguisherhasbeenactivated.

How it works:

Thepresenceofpersonnelisnotneeded.Unitinterventionisdonebysealbulbrupture.

Increaseoftemperatureduringrstperiodofre(93°)willcauseabulbbreaking,followedbythe

dischargeoftheextinguishingunit.Incaseofreinenginecompartment,theoperatorisinformedbya

red light blinking on the pilot desk. Tocheck,usereportinstalledonstarboardsideofsteeringconsole.

ChecktheengineroombypushingopentheFirePort.Incaseofre,putoutusingreextinguisher.

The boat owner/operator shall

-havere-ghtingequipmentcheckedattheintervalsindicatedontheequipment,

-replacereextinguisherifexpiredordischargedbydevicesofidenticalre-ghtingcapacity.

Responsibility of boat owner/operator

a) toensurethatre-ghtingequipmentisreadilyaccessiblewhentheboatisoccupied

b) toinformmembersofthecrewaboutlocationandoperationofre-ghting

equipment

WARNING never obstruct safety controls, e.g. fuel valves, switches of the electrical

system.

WARNING never modify any of the craft‘s systems (especially electrical, fuel) or allow

unqualiedpersonneltomodifyanyofthecraft‘ssystems.

WARNING never smoke while handling fuel.

HAZARDS & SAFETY

m3

m3

Electrical System - Risks of re, explosion or electric shocks

FireorexplosionhazardsthatmayresultfromimproperuseofelectricDCsystems:

a) battery selector switches positioned in engine compartment;

b) For description see pictures of switch panel(s);

c) Information about changing fuses can be taken from the general layout and picture indicating fuse

position, type and capacity;

d) when changing fuse, ensure that engine is not running and ignition and electricity circuit

is OFF.

e) recharging of batteries controlled by automatic voltage sensitve switch:

when disconnecting/reconnecting battery check proper „+/-“ connection.

WARNING never work on the electrical installation while the system is energized.

WARNING never modify the craft‘s electrical system or relevant components.

Installation, alterations and maintenance should be performed by a competent

technician.

WARNING never alter or modify the assessed current amperage of overcurrent

protective devices.

WARNING never install or replace electrical appliances or devices with components

which exceed the rated current amperage of the circuit.

WARNING never leave the craft unattended with the electrical system energized,

exceptautomaticbilgepump,reprotectionandalarmcircuits.

Risk of falling overboard

Should a member of the crew fall overboard, turn the steering wheel to move the propeller away from

the person. Turn off the engine when the person is alongside the vessel and throw him/her a line/lifebuoy/

ladder.

Theyshouldberecoveredusingthexedboardingladderttedtotheboat‘stransom.

HAZARDS & SAFETY

Operating Your Tender

New Engine Break-In Period

NOTICE

Continued wide open throttle runs and

prolonged cruising without speed variations

should be avoided.

This can cause engine damage during the

break-in period.

Abreak-inperiodof10hoursisrequiredbeforecontinuousoperationatfullthrottle.

Amaximumof3/4throttleisrecommendedtoachieveagoodbreak-in.Briefaccelerationandspeedvariations

provide a good break-in.

Steering Sytems

Installedsteeringsystemdesignedexclusivelyforjetboatsfeaturingaarcangle135°locktolock,aspecial

steering cable plus an assortment of mounting options.

Scheme showing parts:

1. Pivot-conduittting

2. Bushing for cable cond. ftg. Pivot

3. Pivot - cable terminal end

4. Bushing for cable term. end pivot

Helm Cable Bracket Hardware Kit

5. Locknut(3/8-24)-conduitttingpivot

6. Lock Washer for 3/8-24 Locknut

7. Locknut (1/4-20) - cable terminal end pivot

8. Lock Washer for 1/4-20 Locknut

9. Hex Bolts (anti-vibratory patch) - bracket

Fuelling

Your new vessel has been thoroughly checked and tested, as well as drained fo fuel prior to delivery.

Please follow these steps when fuelling:

Step 1: Switch off the engine.

Step2: Removetheseatcushioninordertoaccessthellercap.

Step 3: Re-fuel in a ventilated area.

Step4: Donotoverllthetank;also,donotspillfuel.

Step5: Closethefuelcaprmlywhennished.

THEAREAAROUNDTHEFUELFILLERSHOULDNOTBEWETASWATERMAYENTERTHEFUEL

TANK.

CAUTION: NEVER USE FUEL CONTAINING ETHANOL

UseoffuellabeledE15isprohibitedbyUSEPARegulations.

1

2

7

8

3

4

9 (3 Required)

5

6

OPERATING YOUR TENDER

Steering Wheel Removal

CAUTION: DO NOT REMOVE WHILE OPERATING

Step 1: Hold your steering wheel centered from both sides.

Step 2: Pull the quick release to unlatch the steering wheel then pull towards you.

Step 3: To attach the wheel, hold it centered above the shaft and gently push down

until it locks.

NOTE: Grease the mechanism every two weeks and before winter storage

Check List

Caution:Tubesmustbeinatedinthecorrectsequencetopreventover-inationBefore Use

1

1.1 Setvalvesto„closed“andinatetubesevenly,startingatrear/right,rear/left,thenforward

valves.

1.2 Check bilge for fuel or water contamination.

1.3

1.4

1.5

Tighten footwell drain plugs.

Check bilge for fuel or water contamination.

Ensure towing valve is set to open position.

Check that engine cover latches are secure.

The engine must be at operating temperature before an accurate level is indicated on

the dipstick

Oil Level

Check

2

2.1 The oil level should be between MIN and MAX on the dipstick as shown below.

2.2 Do not screw cap into check level.

2.3

2.4

Usethecorrectgradeofoil.(Recommended0W40fullysynthetic)

Donotoverll.

Safety

Check

3

3.1 WARNING: ALWAYS attach the safety lanyard to your leg when engine is running. As a safety

check, test the lanyard for its functionality by pulling it away from its seating - the engine

should stop.

3.2 WARNING: NEVER operate the boat when bathers are using the boarding ladder. The reverse

deectormightcauseseriousinjury.

3.3

2.4

WARNING: NEVER investigate the engine compartment while the engine or the ignition is on.

Donotoverllanyuids.

Check List

Make sure to start your boat in a water depth of minimum 0.9 m /3 ft.Starting

your Boat

4

4.1 Turn on the battery isolator.

4.2 Run engine room blower for 5 minutes.

4.3

4.4

4.5

Secure any loose ropes that could get sucked into the jet unit.

Ensure the shift lever is in neutral position.

Connect the safety lanyard to your leg/body.

WARNING: Personal injury may result if lanyard is not attached!

4.6 Press the ignition button until the engine starts. 1. Battery isolator switch.

2. Keyswitch.

Note:Atleast10secondsshouldbegivenbeforeturningoffthebatteryisolatoraftertheenginehasbeen

switchedoff.NoncompliancewillresultindatalosswithintheenginesECU.

MIN MAX DO NOT THREAD IN TO CHECK!

operating

range

OPERATING YOUR TENDER

Anchoring, mooring, towing and lifting

CAUTION Always tow or be towed at a slow speed. Never exceed the hull speed

when being towed.

CAUTION A tow line shall always be fastened in a way that it can be released

when under load.

The owner/operaor of the boat should ensure that mooring lines, towing lines are

adequate for the vessel‘s intended use.

The craft is equipped with the following strong points:

Item Location Strength, kN (kg)

3MooringCleats seeGeneralLayout 7(700)

1TowingEye ForesideStern 8,5(850)

The owner is responsible for using adequate mooring lines, towing lines and anchor chain and lines.

Thebreakingstrengthofthelinesusedshallnotbemorethan80%ofthebreakingstrengthofthe

associated strong point.

The crew needs to familiarize themselves with the equipment.

TOWING VALVE

CAUTION:Engineoodingmightoccur.Towingvalvetted.

Valve must be in CLOSED (lever vertical) position during towing and

OPEN (lever horizontal) position during use.

Failure to observe correct valve position will result in

serious engine damage.

TOWING VALVE

OPEN FOR

RUNNING TENDER

CLOSED FOR

TOWING TENDER

After Use: Flushing Procedure

Itismandatorytoushengineofsaltwaterafteruseandpriortostorage.Failuretocarryoutushingwill

signicantlyreducethelifeofenginecomponentsandmayinvalidatewarranty.

DO NOT operate throttle out of water.

It is also advised to thoroughly wash the jet pump area with fresh water to remove all salt residues.

CAUTION:EngineMUSTbeonbeforewaterisconnected.Riskofengineoodingexistsifwater

remains on after the engine has been switched off.

1. Connectafreshwaterhosetotheushingattachmentcoupling.Pressouterringtoengageand

release adaptor.

2. Start engine.

3. IMMEDIATELY turn the water supply on.

4. Runengineatidleforapprox.1minutetocompletelyushtheopenloopcoolingsystem.

5. Turn off water supply.

6. Allowtheenginetorunfornolongerthan10secondstoallowwatertoexitthecoolingsystem,then

turnofftheengine.Disconnectthehoseformthetheushingattachment.

7. Check bilge of boat and dry any residual water. Remove footwell drain plugs.

Accelerate & Brakes

Thethrottle/gearleversarettedontherighthandsideofthesteeringwheel.

Theleft(red)levercontrolsthethrottlefrom0(leverdown)to100%(leverup).Therightleverhas2positions:

1. Middle (Forward / Neutral)

2. Down (Rear)

To move forward, the right lever has to be in the middle position. To engage the forward gear, gently push the

left (throttle) lever forward. This will move the craft forward. The throttle lever controls the speed.

Pushing the right lever down will engage the brake. In order to stop the craft, hold the right lever down and set

thethrottleto0%.Whenthecrafthascometoastop,movetherightleverbacktothemiddleposition.This

will engage the neutral gear.

For further information contact your authorized dealer.

1. Start / Stop Button

2. Bilge Pump Buzzer

3. Fire Extinguisher Alarm Button

4. Throttle Lever

5. Gear Lever

5

3

2

1

4

OPERATING YOUR TENDER

General Layout

1. Front step-plate with rope roller and navigation lights

2. „Push-down“ mooring cleat

3. Front seat (splash-water-resistant locker under seat)

4. Front / Rear lifting points

5. Front foot well drain

6. Strap handles

7. Seat(fueldeckllerunderneath,starboardside)

8. Side step plates

9. Engine compartment cap with white all-roung light

10. Aft foot wells drains

11. Aft lift points

12. Pilot seat

13. Grab rails

14. Towing ring

15. Swimming platform (foldable retract)

16. Aft step plates

17. Drain plugs

18. Drainskinttings

19. Flushing connector

20. Bilge pump outlet

21. Tie-down rings

22. Retractable ladder

23. CraftIdenticationNumber

24. Depth Transducer

23

21

22 20

17 17

19

21

18

330

305

23

21

21

17

17

22

19

18

24

GENERAL LAYOUT

12

3

4

4

65

7

8

8

9

10

10

11

11

12

13

13

14 15

16

16

NOTES:

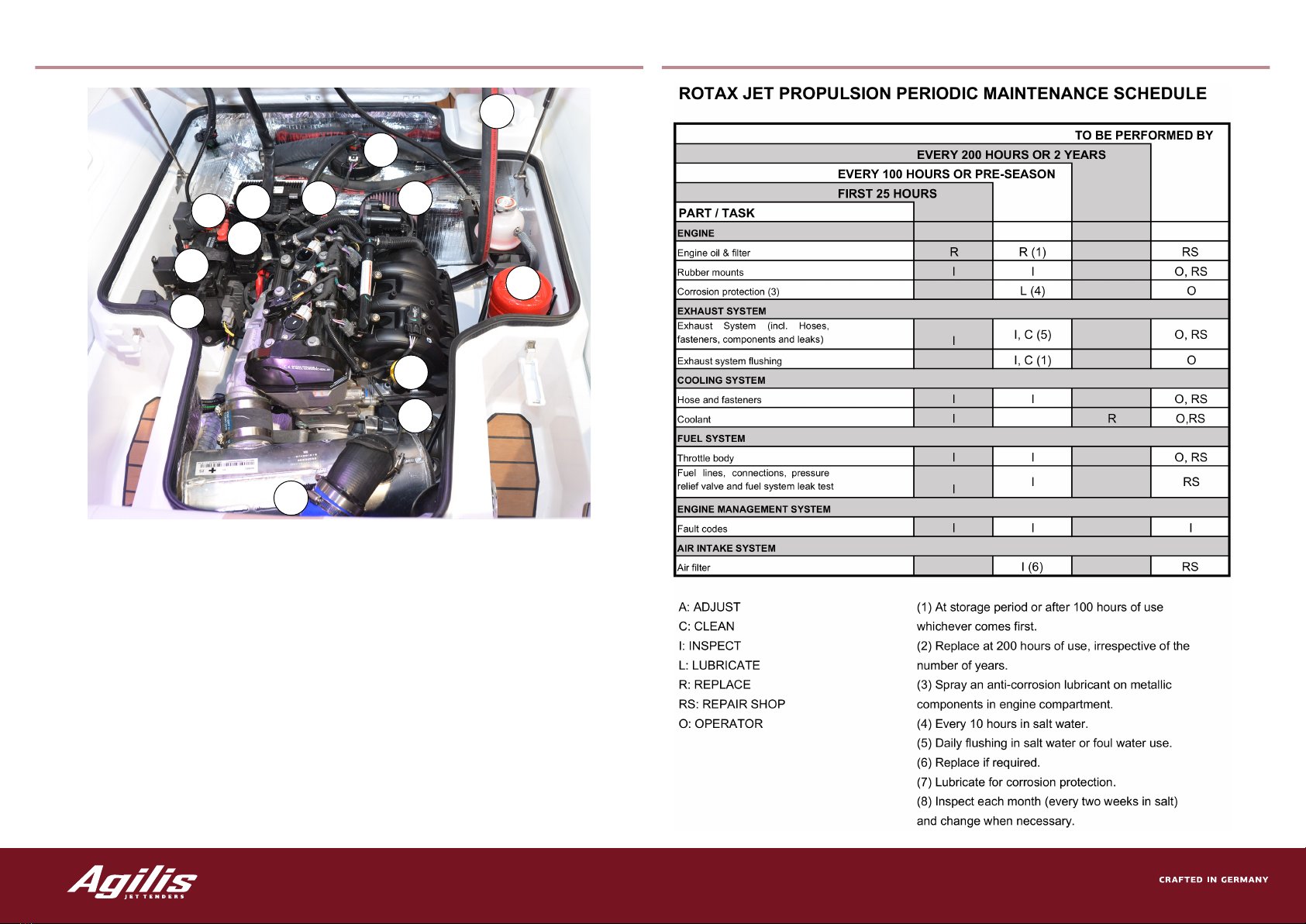

Engine Compartment

3

1

6

5

4

11

8

12

10

9

7

2

3

1. Towing Valve

2. MainCircuitBreaker(50amp)

3. Battery Switch

4. Service Battery

5. Bilge Pump

6. Fuel Tank

7. Deck Filler (fuel)

8. Engine Air Filter

9. EngineBattery

10. OilDipstick

11. GasFireExtinguisher

12. Engine Oil Filter

GENERAL LAYOUT

Full Inspection Maintenance Table

Winter Storage

Due to temperature changes and humidity, the boat has to be stored in a dry and aerated place.

Buoyancy Tube:

Beforestoringyourboat,deateandrinsethetubesthoroughlytoremovealldebris.Leavetodrybefore

polishing.Thetubesshouldbestoredslightlyinated.

Battery:

Thisboatusesawetcellbattery.WhenstoringtheboatforWinter,disconnecttheearthterminal.Usean

accumatetoextendbatterylife.

Fuel System:

Fillthetankcompletelybeforestorage.Useafuelstabilizertominimisefuelbreakdown.

Cables:

All control cables should be greased at both ends.

Cooling System: Proceed as in chapter Flushing Procedure to remove debris that may be found in the raw

watercoolingcircuit.Checktheanti-freezecontentoftheenginecoolant.Usefrostprotectionsuchasdistilled

watermixedwithpropyleneglycoltoa1:1ratio.Usethesamemixtureintheopenloopsystem.

Engine Oil:

The engine oil should be changed prior to storage. Leaving used oil in the engine for longer periods may cause

corrosion.

Cylinders:

Approximately10mlofcleanengineoilshouldbelledintoeachsparkplug.Starttheengineafewtimes

before screwing back the spark plugs.

Hull & Deck:

Thedeckshouldbecleansedonaregularlybasis.Useamilddetergentandwarmwater.Rinsethoroughlyto

removedebris.BothhullanddeckshouldbepolishedregularlytoprotectfromUVchalking.

Corrosion Protection:

White grease, i.e. Vaseline, should be applied to the battery isolator switch, upholstery press studs and the

running light pole base. Spray the key switch with a maintenance spray. Engine, electrical connections, helm,

and jet pump area should be maintained with corrosion guard.

WINTER STORAGE

Agilis Warranty

Ourwarrantycoversyourboatfor2yearsor60hoursfromthedateoftheoriginalregistration.

On purchasing a craft, Agilis provides you with with the original registration card. This card should

belledandsentbacktoAgiliswithin30daysafterregistration.

Agilis guarantees to the original purchaser that all seams of the ination valves, tubes and the

fabricusedtoconstructthetubeswillbeawlessoveraperiodof3yearsfromthedateoforiginal

registration.

Forcommercialuseourwarrantycoversyourvesseloveraperiodof4monthsor60hoursfromthe

original date of registration. Agilis warranty is limited to repairing or replacing defective parts.

AgilisWarrantyDOESNOTCOVERnormalwearandtear,anyminorboatdamage,tubesexposed

to corrosive chemicals, parts installed by third party personnel, boats purchased for commercial or

governmental use, defects caused by non-adherence to instructions.

The warranty claim must be approved in writing by Agilis Jet Tenders. The original owner must send

awrittennotication,acopyofhisreceipt,aphotographofthedamageto

Agilis Jet Tenders, Lohfeldstr. 2, 52428 Jülich, Germany

ofce:(+49)2461-3403330

fax:(+49)2461-34033313

Afterapproval,Agiliswillsendawrittennoticationtotheownerwheretosendtheboatforrepairor

replacement. Repairs will either be taken place by authorized dealers or Agilis Jet Tenders.

Agilis Jet Tenders do not guarantee any work carried out by unauthorized personnel.

All parts replaced under this Warranty become the property of Agilis Jet Tenders.

WARRANTY

Notes

NOTES

We hope that this handbook will help you getting started with your new vessel. It has been

conceivedtobecompactsothattheimportantchaptersareeasytond.

In case you need more support, do not hesitate to contact your authorized dealer or

Agilis Jet Tenders for any inquiries.

We wish you a pleasant trip !

This manual suits for next models

1

Table of contents

Popular Boat manuals by other brands

Rinker

Rinker Cruisers Owner's/operator's manual

Wave Sport

Wave Sport WHITEWATER owner's manual

KAYACAT

KAYACAT PUMA Assembly instructions

Pro-Line Boats

Pro-Line Boats 2010 35 Express owner's manual

KL Industries

KL Industries WaterWheeler ASL Electric owner's manual

Grand

Grand GOLDEN LINE G340N owner's manual