51.800.627.4499

Subject to change without notice: RENEWAIRE.COM | 1.800.627.4499 54 Subject to change without notice: RENEWAIRE.COM | 1.800.627.4499

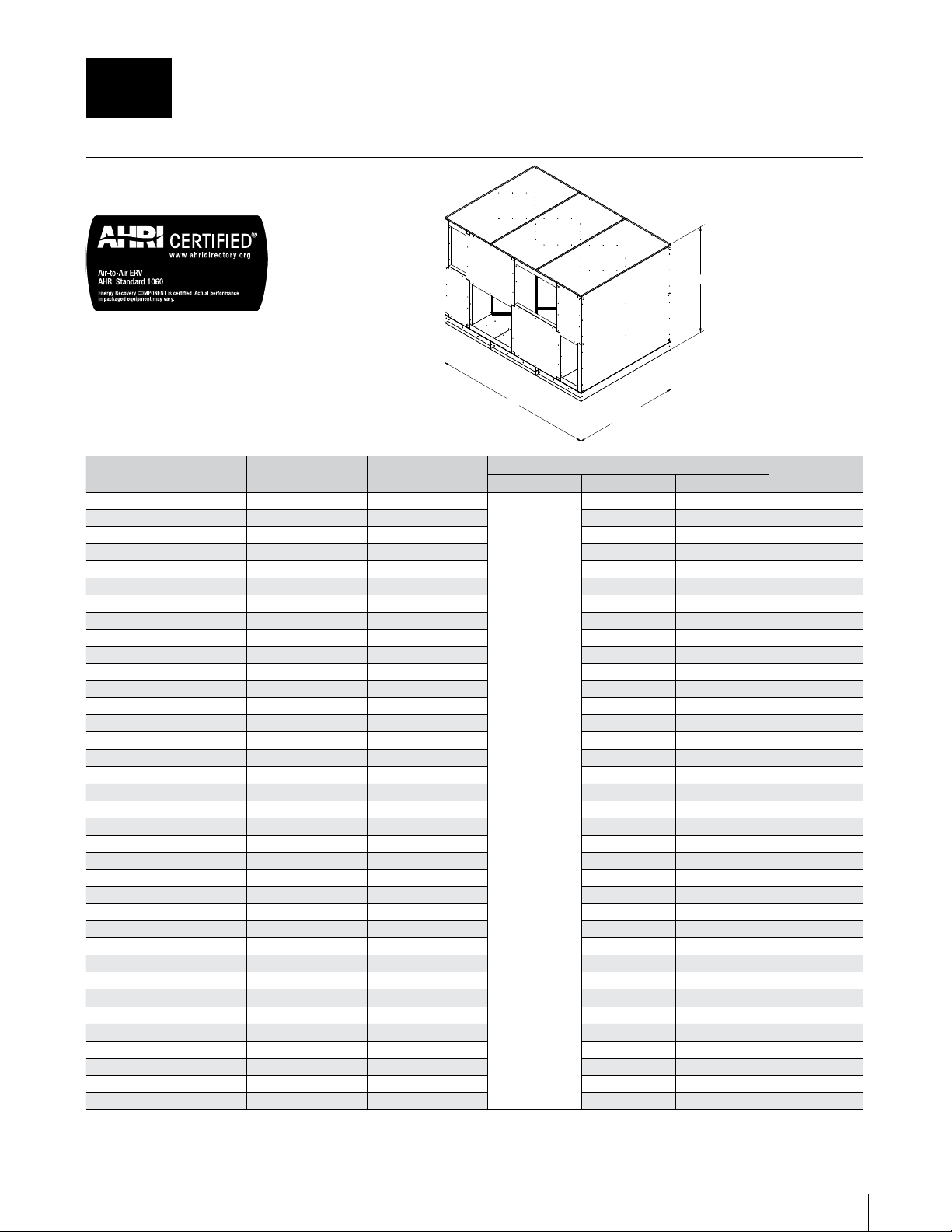

SPECIFICATIONS & DIMENSIONS

Unit

(Cores High and Wide)

Typical Airflow Range

(CFM)

AHRI 1060 Certified

Cores (L125-G5)

Unit Dimensions Weight

(lbs.)

L (Inches) W (Inches) H (Inches)

SA3H3W 2,250–9,900 9

64 1/2

97 3/4 65 5/8 1,300

SA3H4W 3,000–13,200 12 130 1/4 65 5/8 1,675

SA3H5W 3,750–16,500 15 162 7/8 65 5/8 2,049

SA3H6W 4,500–19,800 18 195 3/8 65 5/8 2,424

SA3H7W 5,250–23,100 21 228 65 5/8 2,798

SA3H8W 6,000–26,400 24 260 1/2 65 5/8 3,172

SA4H3W 3,000–13,200 12 97 3/4 85 1/2 1,582

SA4H4W 4,000–17,600 16 130 1/4 85 1/2 2,030

SA4H5W 5,000–22,000 20 162 7/8 85 1/2 2,479

SA4H6W 6,000–26,400 24 195 3/8 85 1/2 2,927

SA4H7W 7,000–30,800 28 228 85 1/2 3,376

SA4H8W 8,000–35,200 32 260 1/2 85 1/2 3,825

SA5H3W 3,750–16,500 15 97 3/4 105 3/8 1,863

SA5H4W 5,000–22,000 20 130 1/4 105 3/8 2,384

SA5H5W 6,250–27,500 25 162 7/8 105 3/8 2,908

SA5H6W 7,500–33,000 30 195 3/8 105 3/8 3,431

SA5H7W 8,750–38,500 35 228 105 3/8 3,954

SA5H8W 10,000–44,400 40 260 1/2 105 3/8 4,477

SA6H3W 4,500–19,800 18 97 3/4 125 1/2 2,203

SA6H4W 6,000–26,400 24 130 1/4 125 1/2 2,819

SA6H5W 7,500–33,000 30 162 7/8 125 1/2 3,435

SA6H6W 9,000–39,600 36 195 3/8 125 1/2 4,051

SA6H7W 10,500–46,200 42 228 125 1/2 4,666

SA6H8W 12,000–52,800 48 260 1/2 125 1/2 5,282

SA7H3W 5,250–23,100 21 97 3/4 145 3/8 2,483

SA7H4W 7,000–30,800 28 130 1/4 145 3/8 3,174

SA7H5W 8,750–38,500 35 162 7/8 145 3/8 3,864

SA7H6W 10,500–46,200 42 195 3/8 145 3/8 4,554

SA7H7W 12,250–53,900 49 228 145 3/8 5,244

SA7H8W 14,000–61,600 56 260 1/2 145 3/8 5,934

SA8H3W 6,000–26,400 24 97 3/4 165 1/4 2,765

SA8H4W 8,000–35,200 32 130 1/4 165 1/4 3,529

SA8H5W 10,000–44,000 40 162 7/8 165 1/4 4,294

SA8H6W 12,000–52,800 48 195 3/8 165 1/4 5,058

SA8H7W 14,000–61,600 56 228 165 1/4 5,822

SA8H8W 16,000–70,400 64 260 1/2 165 1/4 6,587

Performance:

Model: SA3H3W CATALOG

Drawing Type: Unit Dimension

Cross flow arrangements have best thermal

performance compared to parallel flow arrangements.

See IOM for complete thermal performance.

Version: FEB20

1 = OA: Outside Air intake

2 = SA: Supply Air to inside

3 = RA: Room Air to be exhausted

4 = EA: Exhaust Air to outside

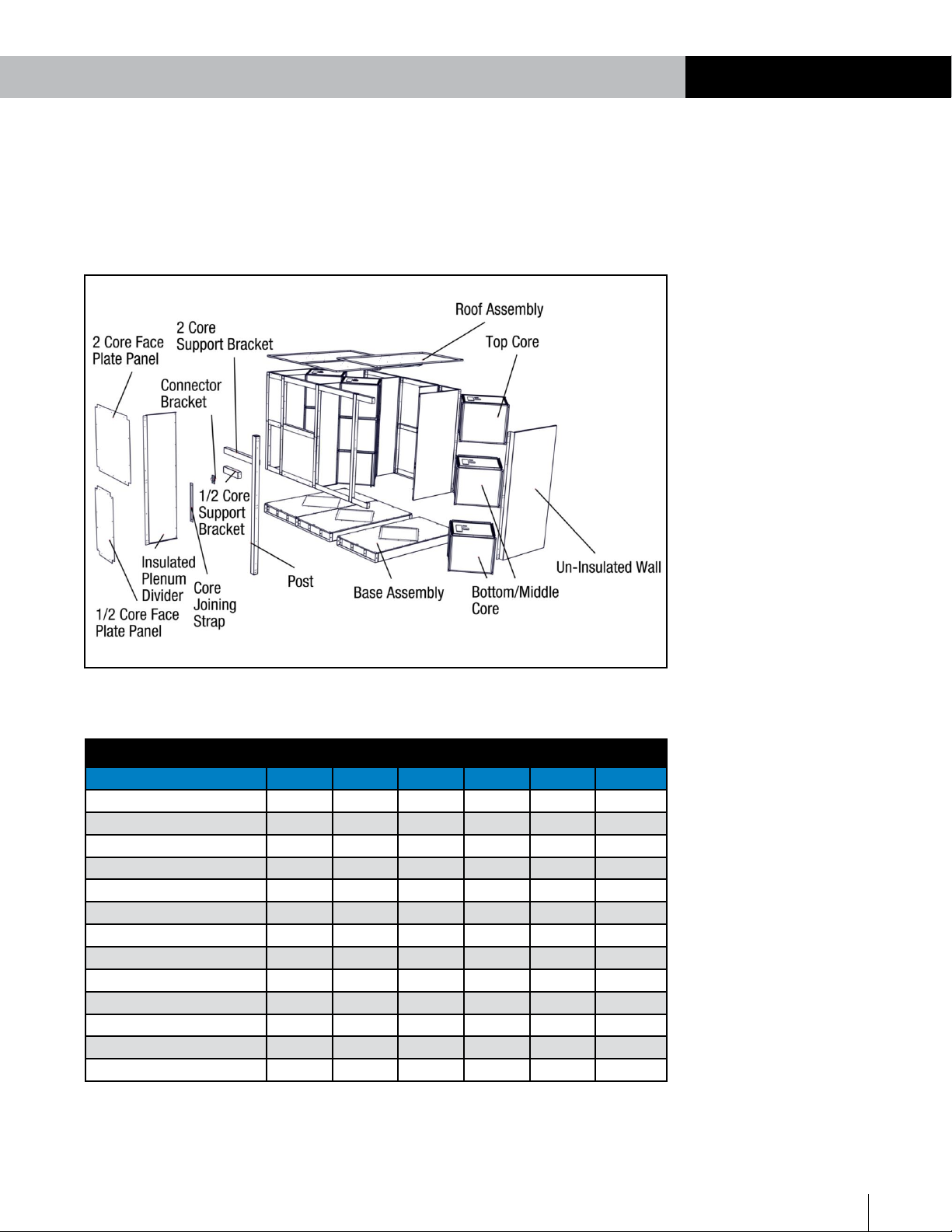

INSTALLATION ORIENTATION

Unit must be installed in orientation

shown.

NOTE:

1. UNLESS OTHERWISE SPECIFIED,

DIMENSIONS ARE ROUNDED TO THE

NEAREST EIGHTH OF AN INCH.

2. SPECIFICATIONS MAY BE SUBJECT

TO CHANGE WITHOUT NOTICE.

3. FILTERS REQUIRED ON UPSTREAM

SIDE OF CORES.

4. UNIT WILL SHIP DISASSEMBLED AND

REQUIRES ON-SITE ASSEMBLY.

5. DUCT WORK SUPPLIED BY OTHERS.

6. AIR STREAMS 1-2 CAN BE

INTERCHANGED WITH AIRSTREAMS 3-

4. EACH AIRSTREAM IS REVERSIBLE.

W

L

64 1/2"

H

SA SERIES DIMENSIONS

SERIESSA Energy Recovery Core Array

Energy Recovery Core is AHRI Certified®