D . DESCRIPTION OF THE ALGLASS BURNER

Built to operate on various types of glass making furnaces, the material used is especially suited for this

purpose.

In general, the metals used offer a good resistance to corrosion for the burner's "cold part", and good

resistance to temperature and oxidation for the "hot part".

Generally speaking, all of the metal alloys employed are perfectly compatible with pure oxygen using.

Each burner metal component part bears its production file number.

The burner block is refractory material. This refractory material is chosen to be compatible with the

particular glass making process and the type of superstructures.

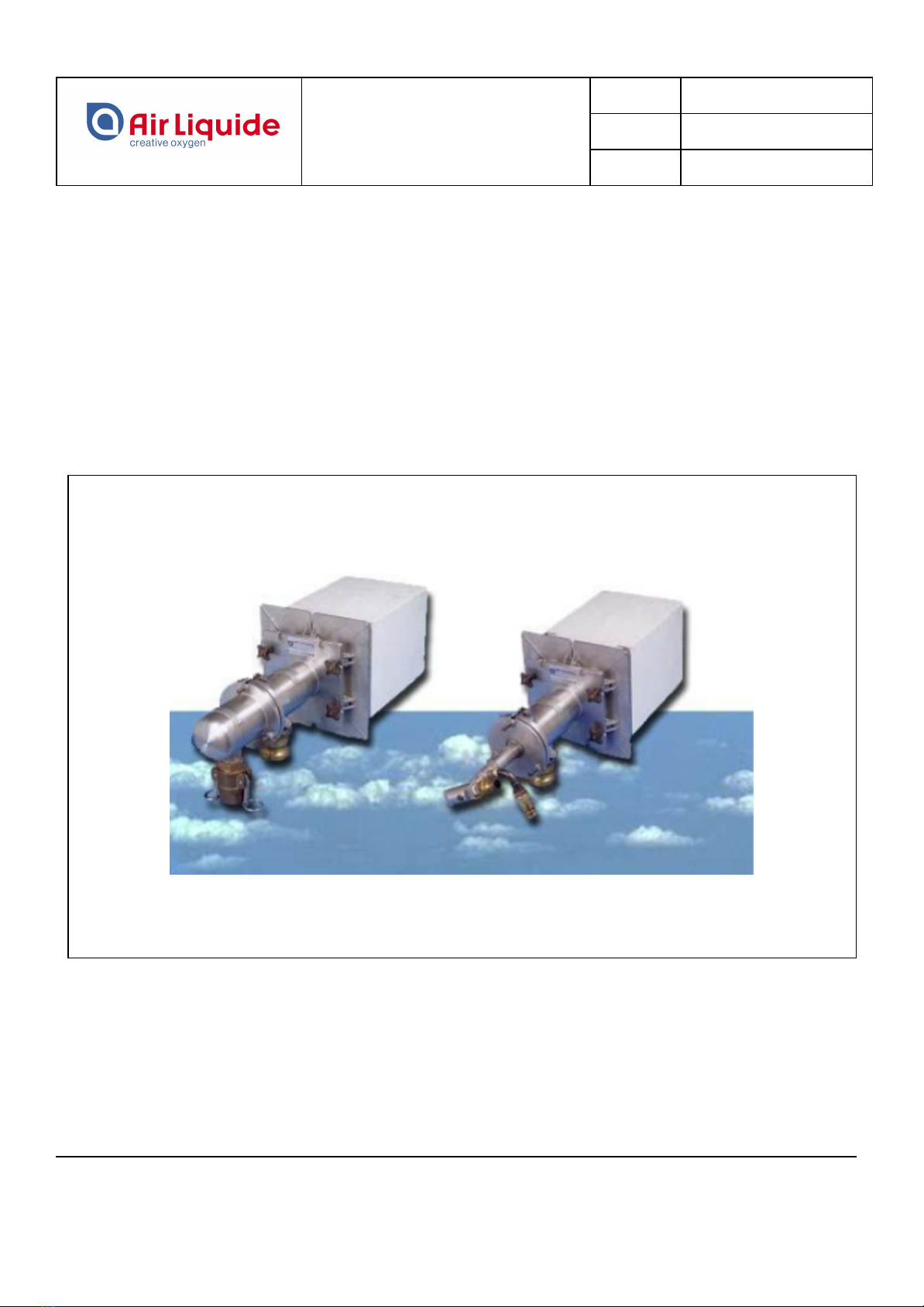

The gaseous fuel version of the ALGLASS burner comprises six component parts, and the liquid fuel

version comprises five parts.

The gas/fuel oil burner consists of the following parts. (Fig.1)

●The burner block made of refractory material.

●The fixation system for mounting the burner body on the block, consisting of two half sections.

●A ceramic packing to be positioned between the burner block and the burner body.

●The burner body with its VITON O-ring, mounted in the flange groove and a closing flange to be

mounted back on the body.

●A gas lance with 1, 3 or 5 tubes.

●A dual lance with injector and nozzle

All data shown on this page are subject to change without notice.

This document contains proprietary information of AIR LIQUIDE.

They cannot be copied nor disclosed to a third party without its previous consent.