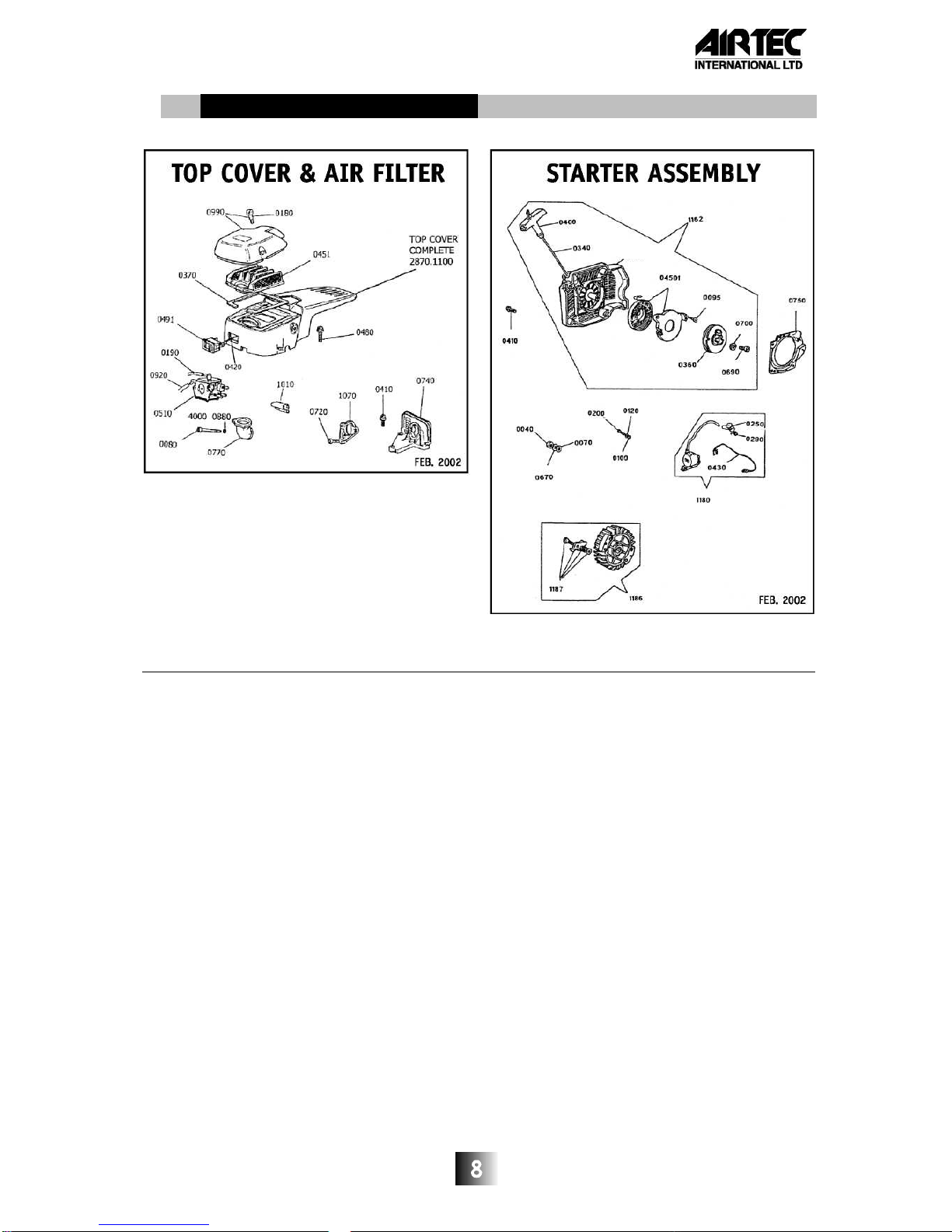

8. DISMANTLING MOTOR (See Exploded Diagram Drawings on Pages 8, 9, 10, 14 & 16 .

1. REPLACEAIRFILTER4003.0451

Unfasten two Screws 0180 on Filter Cover

0990 and lift off. Remove and replace Air

Filter.

2. REMOVINGTOPCOVER2870.1100

Loosen three Screws 0480. Push rubber air

intake 0770 through Top Cover. Remove wires

from On/Off Switch 0491 noting position for re-

connecting. Refit using Air Intake Tool Part

No. 4002 9005.

3. REPLACINGFUELPRIMER

ASSEMBLY4003.0810

Remove Screws 2303.0315 and take off Bulb

Protector 2650.1010 and pull Primer from

Motor.

Please note : for Primer re-connection connect

Pipe 1190 from Fuel Tank to "out" port and Pipe

0910 from the Carbrettor "in" port.

4. REPLACINGSTARTER

RECOILSPRING4003.04501

Follow procedure for replacing Pull Cord -

See 7.4 on Page 6.

With the pulley separated from Starter

Housing, remove the two Screws.

Remove old Spring Cassette and replace

with new one. Refit screws.

When refitting Starter Housing pull Starter

Cord to ensure it operates before tightening

Screws.

Please Note:

TheSpringintheCassetteCaseis

pre-tensioned. Always handle with care.

5. REMOVINGFLYWHEEL

4003.1186

Fit Piston Stop Tool 10.00022 into Cylinder

and remove Flywheel Nut 0040. Remove

Flywheel Ratchet Assembly1187. Using

Puller 10.00049 with Screws 10.00362 remove

Flywheel. Take care not to lose Key0220.

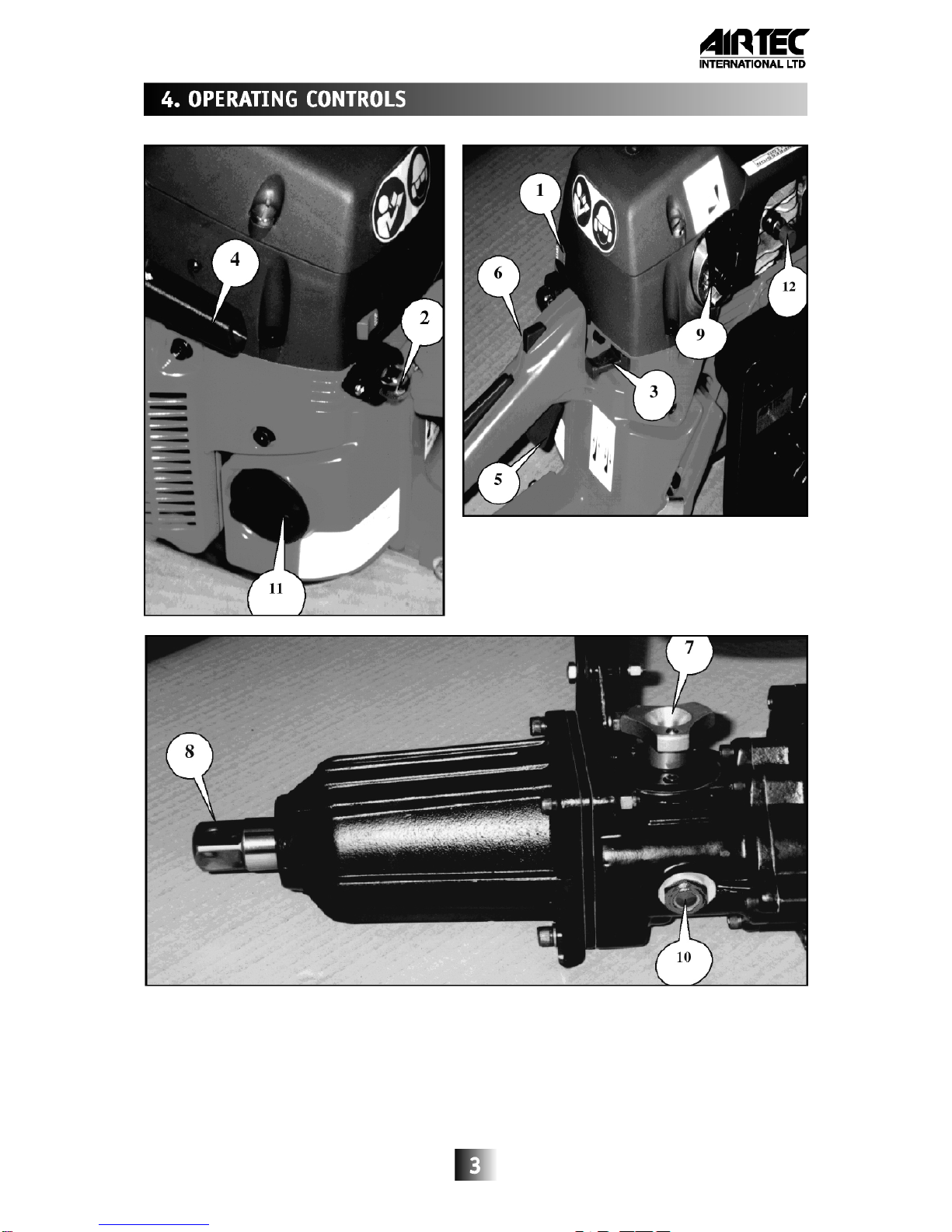

6. REMOVINGEXHAUSTGUARD8AND

MUFFLERASSEMBLY4003.0850

Remove five Screws 7 holding Exhaust

Guard and lift off. Unfasten two Screws 0640

on inside of Exhaust Box and remove it and

Gasket 0860 from Motor.

Ensure Motor/Muffler is warm when

re-fitting Screws

7. REMOVING THECARBURETTOR

4003.0510

RemovetwoScrews0080, Screw0720 andFuel

Pipes 0190 & 0920 from Carburettor making

sure to note re-connecting positions.

Disconnect Choke Linkage 0880 and Throttle

Linkage 1020 and remove Carburettor.

8. DISMANTLINGMOTORFROM

IMPACT UNIT

Remove Carrying Handle 97 and four Screws

24 holding Clutch Support Flange 18 to Engine

Flange 9. Pull apart.

9. REMOVINGCYLINDERANDPISTON

4003.1165

Remove three Screws 0410 holding Carburettor

Flange 0740 to Casing. Depress Spring Clip

0390 behind Carburettor Flange and pull from

Cylinder. Loosen four Screws 0630 holding

down Cylinder and lift off. Remove Spring Clip

4001 4200 from inside Piston and Gudgeon Pin

0800. Lift off Piston 1120. Check Piston Rings

0820 for wear and replace if necessary.

Rebuild in reverse order.

Please Note: If Clutch is to be removed

leave Cylinder and Piston in position until

after this is done.

10. REMOVINGCRANKCASE4003.1150

& 4003.1169 FROM FUEL TANK

4003.1045

Remove Screws 0110 to allow Crankcase to

be disconnected from Fuel Tank.

11. REMOVINGCRANKSHAFT 4003.0985

Remove seven Screws 4001.1100 from Clutch

side of Crankcase. Run Flywheel Nut 0040

onto Crankshaft 0985 until flush with the end.

Hold Crankcase tightly and using a soft faced

mallet tap against the Flywheel Nut until the

Casing splits.

Please Note: a) It is advisable to replace all Gaskets

and Seals when rebuilding Motor.

b) If Primer Bulb 0810 is burst

disconnect two Fuel Pipes 0910 and

1190 and plug the holes.

DO NOT CONNECT THE PIPES

TOGETHER Replace Primer Bulb

Assembly as soon as possible. (see

section 8.3)

7