New Master 35 Petrol/Gasoline Impact Wrench

BEFORE using the Impact Wrench read these safety instructions CAREFULLY and ensure you fully

UNDERSTAND them. DO NOT allow untrained personnel to use the Wrench.

1. Wear suitable PROTECTIVE CLOTHING, safety

boots, goggles, gloves and ear protection

according to Company rules, working

conditions or Government/State Legislation.

2. The effect of vibration exposure can be

REDUCED by following a number of simple

rules :-

a) Always wear protective gloves and keep

hands warm and dry.

b) Ensure Wrench is properly maintained.

c) Do not use worn Sockets and ensure

Wrench Anvil is replaced when worn.

Use of our NO GO GAUGE allows quick

and easy checks on Socket Square

Drive and Anvil wear.

d) Share the workload whenever possible.

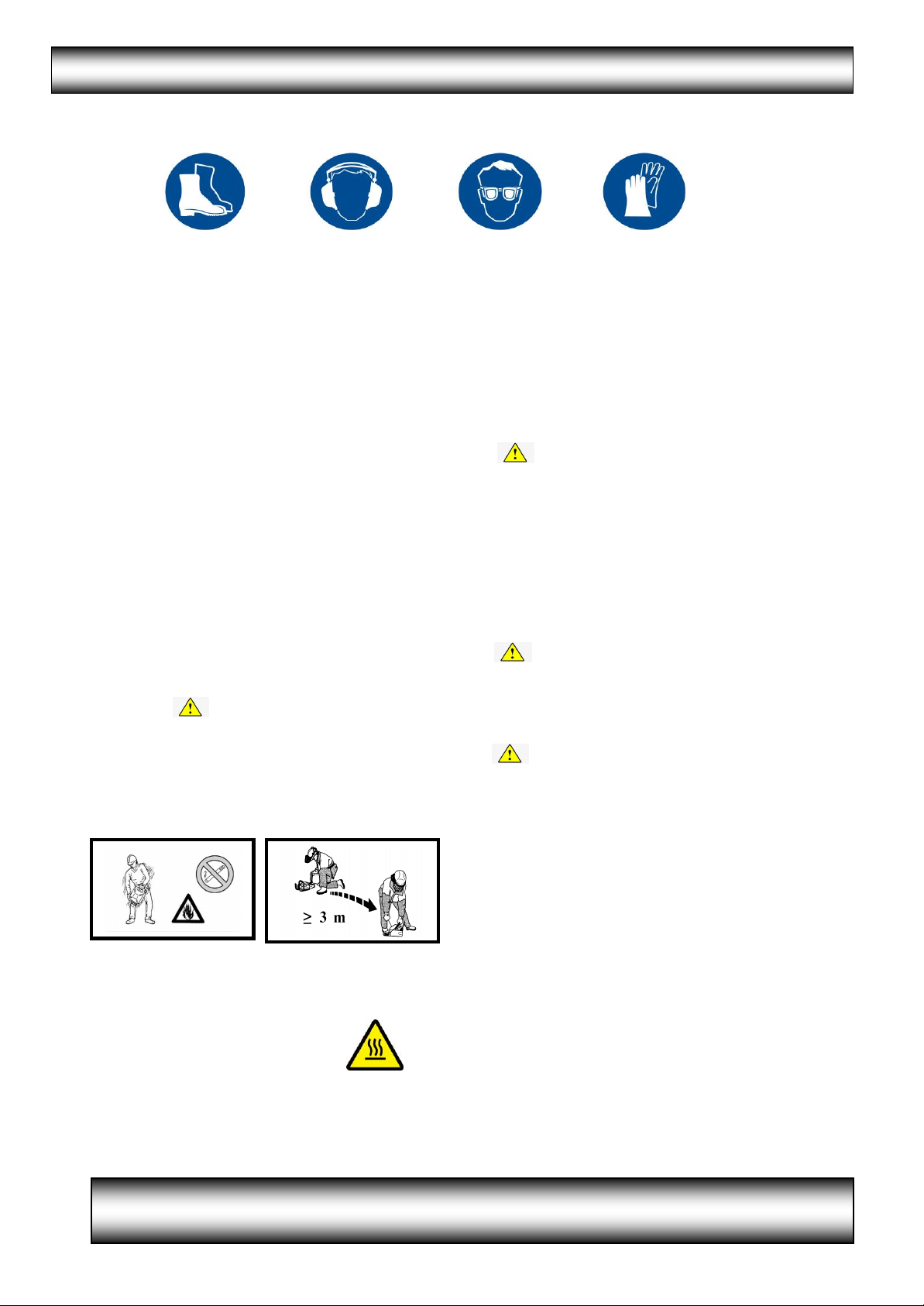

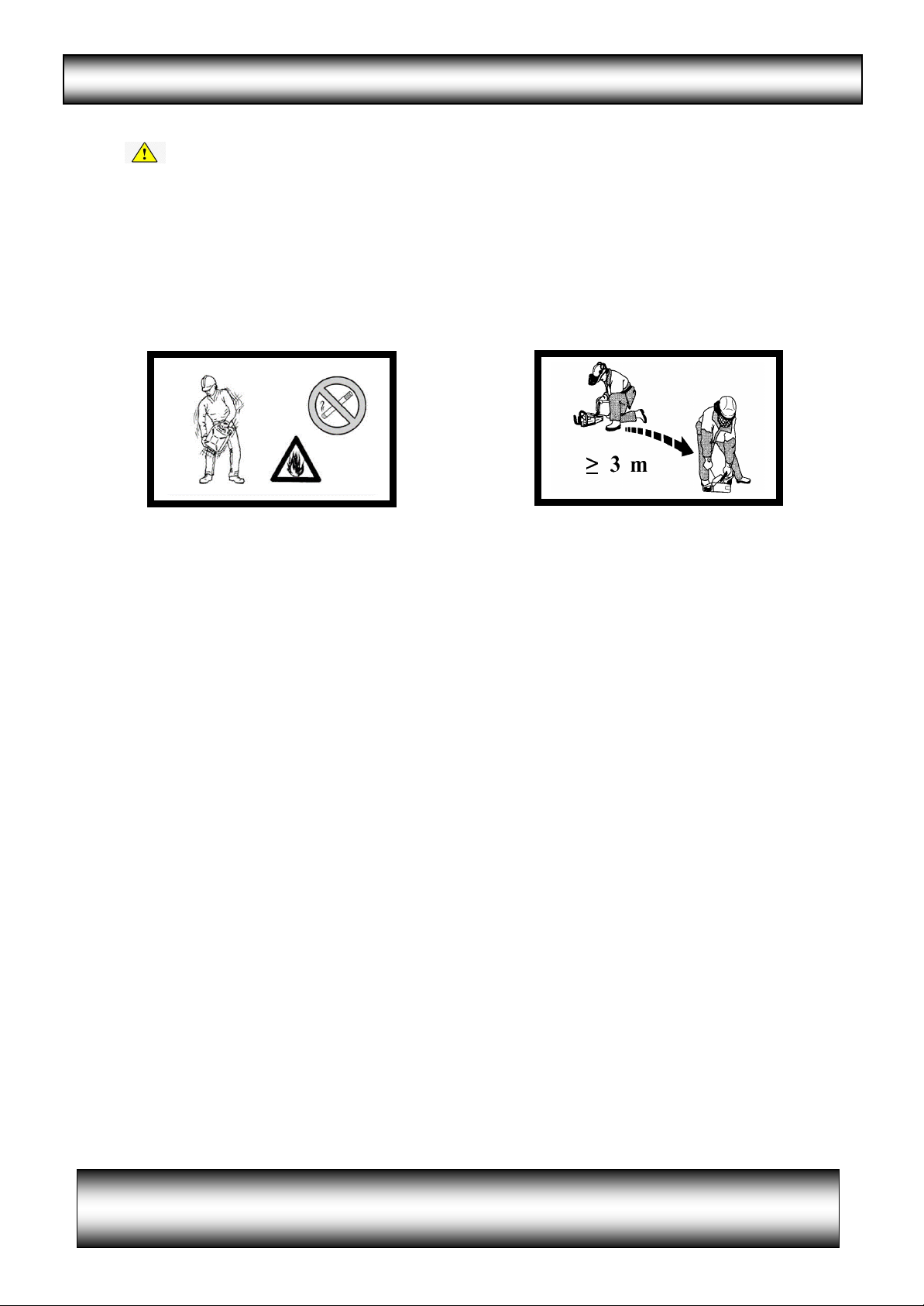

3. FILL the fuel tank carefully BEFORE starting the

Wrench in a well ventilated area and avoid

spillage. Use the Fuel Funnel provided or a

Safety Fuel Can. DO NOT fill or add oil while the

Motor is running. Allow machine to cool before

re-fueling, DO NOT over fill, allow for

fuel expansion. Keep well away from naked

flames or equipment which generates sparks

e.g Rail Saw or Rail Grinder. Do not leave the

mixture in the fuel tank for any prolonged

period of time.

4. The exhaust is fitted with a Catalytic

Converter to reduce emission levels to meet

EUR5 and EPA 3 Standards.

It will become HOT during and

after use.

Please AVOID direct contact.

5. Know where the controls are and how to

use them and be able to STOP the Wrench

quickly in an emergency.

6. Do Not Operate in confined spaces because of

the danger of Carbon Monoxide being present.

7. Remove FUEL FILLER CAP CAREFULLY as

pressure can build up in the tank. This is very

important in warm weather, if the Wrench has

been left in an exposed area or after

prolonged periods of use.

8. Do not wear hanging jewellery, a tie or

loose or torn clothing.

9. Take up a FIRM footing and maintain a balanced

body position

10.Check pull cord is not frayed or worn.

11.Use only IMPACT QUALITY Sockets and

Accessories

HAND Sockets must NEVER be used

12.Use Rubber Rings and Steel Pins or other

suitable retaining devices to retain the

Socket or Accessory onto the Square Drive.

DO NOT use twigs, wire, nails or plastic

straps.

13.Set the GEAR CONTROL in NEUTRAL before

starting.

14.Check the Wrench for damage regularly.

Ensure fasteners are tight at all times.

A poorly maintained Wrench will be inefficient

and produce extra noise and vibration

15.Switch OFF ENGINE BEFORE transporting

the Wrench to another location.

16.Take CARE when LIFTING or carrying the

Wrench - weight with fuel and excluding

accessory approximately 18.5Kgs (40 ¾ lbs)

17.The engine has a break in period of 5 to 8

hours. During this time the engine may emit

some smoke.