9

Instructions for using the Vacuum Equalizer with VacStar & STS units:

1. The vacuum relief valve on all units controlled by the Vacuum Equalizer

must be set to the same vacuum level. Set vacuum relief valve on each

unit using the same vacuum gauge.

2. The vacuum relief valve on the pumps must be set higher than the

high vacuum setting of the Vacuum Equalizer. (i.e. if the high setting

on the Vacuum Equalizer is set to 9 in-Hg the vacuum relief valve on

the pumps should be set to 10 In-Hg).

3. The low vacuum setting on the Vacuum Equalizer can be set to 6, 7 or

8 in-Hg, depending on what the end user requires.

4. The delay on and delay off time settings of the Vacuum Equalizer can

be set to their lowest values for the greatest electric and water savings.

Note that if a pump turns “ON” and “OFF” three times within an

hour it will stay powered on for an additional hour before returning to

normal operation. If this happens repeatedly it may be beneficial to

increase the delay off time to prevent this from happening.

Instructions for using the Vacuum Equalizer with VacStar NEO units:

1. Up to four VacStar 20 NEO or four VacStar 40 NEO or two VacStar

50 NEO or two VacStar 80 NEO unit can be controlled by the Vacu-

um Equalizer.

2. All the units must be the same. Do not mix VacStar NEO models.

3. The vacuum settings on all the VacStar NEO pumps must be set to the

same value.

4. The vacuum setting on the VacStar NEO pumps must be set to 1

in-Hg higher than the high vacuum setting of the Vacuum Equalizer.

(i.e. if the high setting on the Vacuum Equalizer is set to 9 in-Hg the

vacuum setting on the VacStar NEO should be set to 10 In-Hg).

5. The low vacuum setting on the Vacuum Equalizer can be set to 6, 7 or

8 in-Hg, depending on what the end user requires.

6. The delay on and delay off time settings of the Vacuum Equalizer can

be set to their lowest values for the greatest electric and water savings.

Note that if a pump turns “ON” and “OFF” three times within an

hour it will stay powered on for an additional hour before returning to

normal operation. If this happens repeatedly it may be beneficial to

increase the delay off time to prevent this from happening.

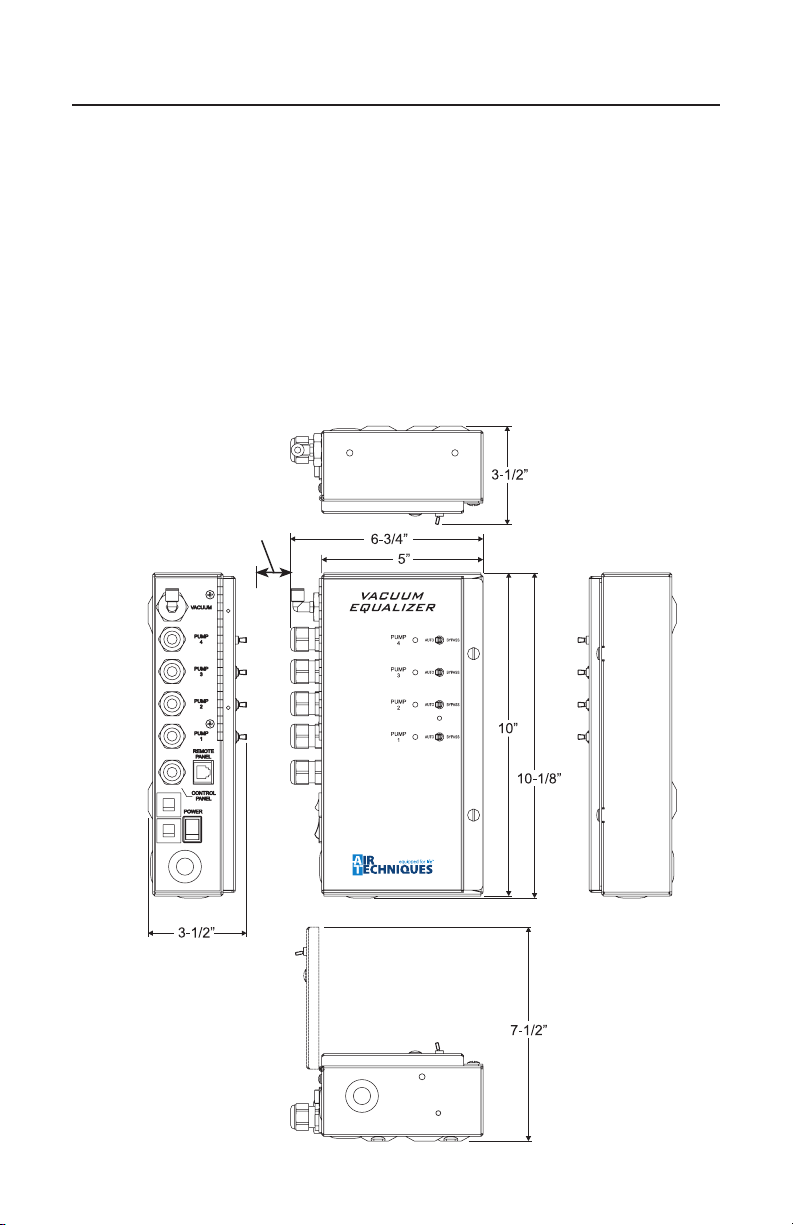

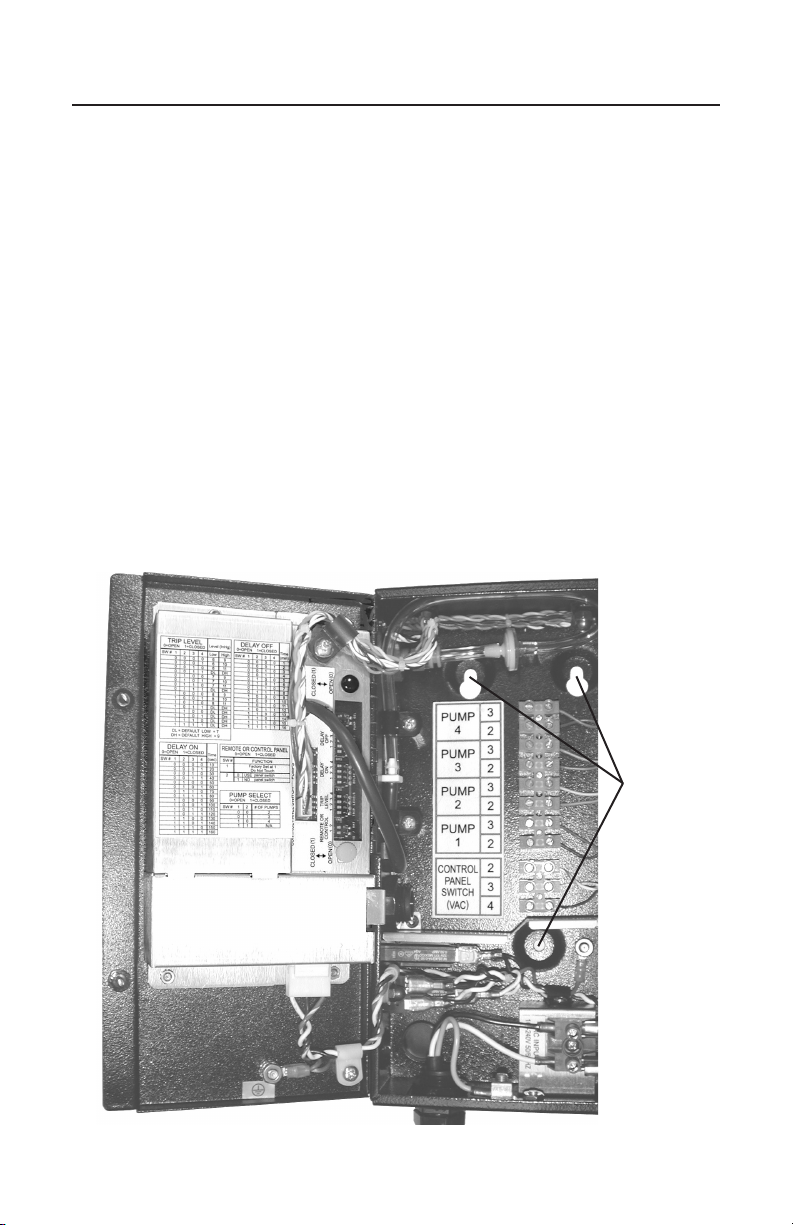

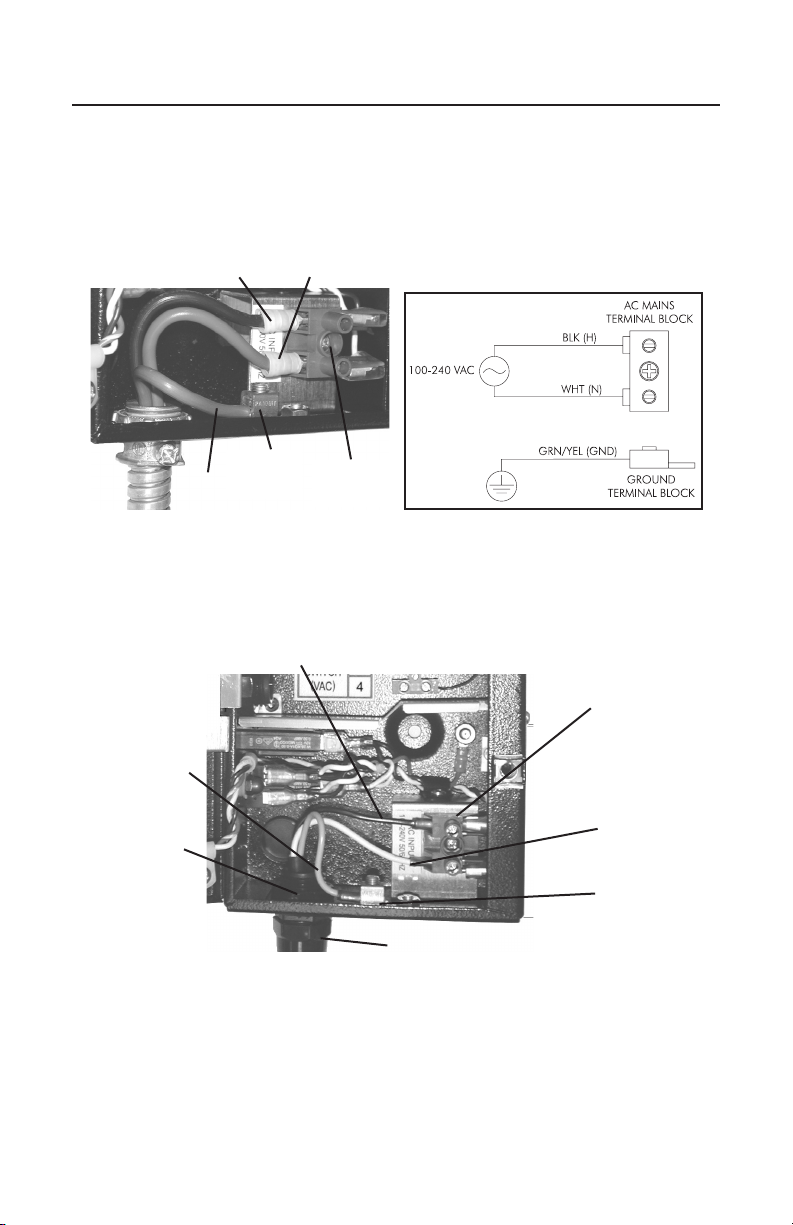

INSTALLATION INFORMATION