1

1.GENERALITES .............................................................................................................................................. 1

2.PRESENTATION ........................................................................................................................................... 3

3.INSTALLATION ............................................................................................................................................. 3

Choice of the place ............................................................................................................................................ 3

Implantation ........................................................................................................................................................ 3

Reception – Storage .......................................................................................................................................... 3

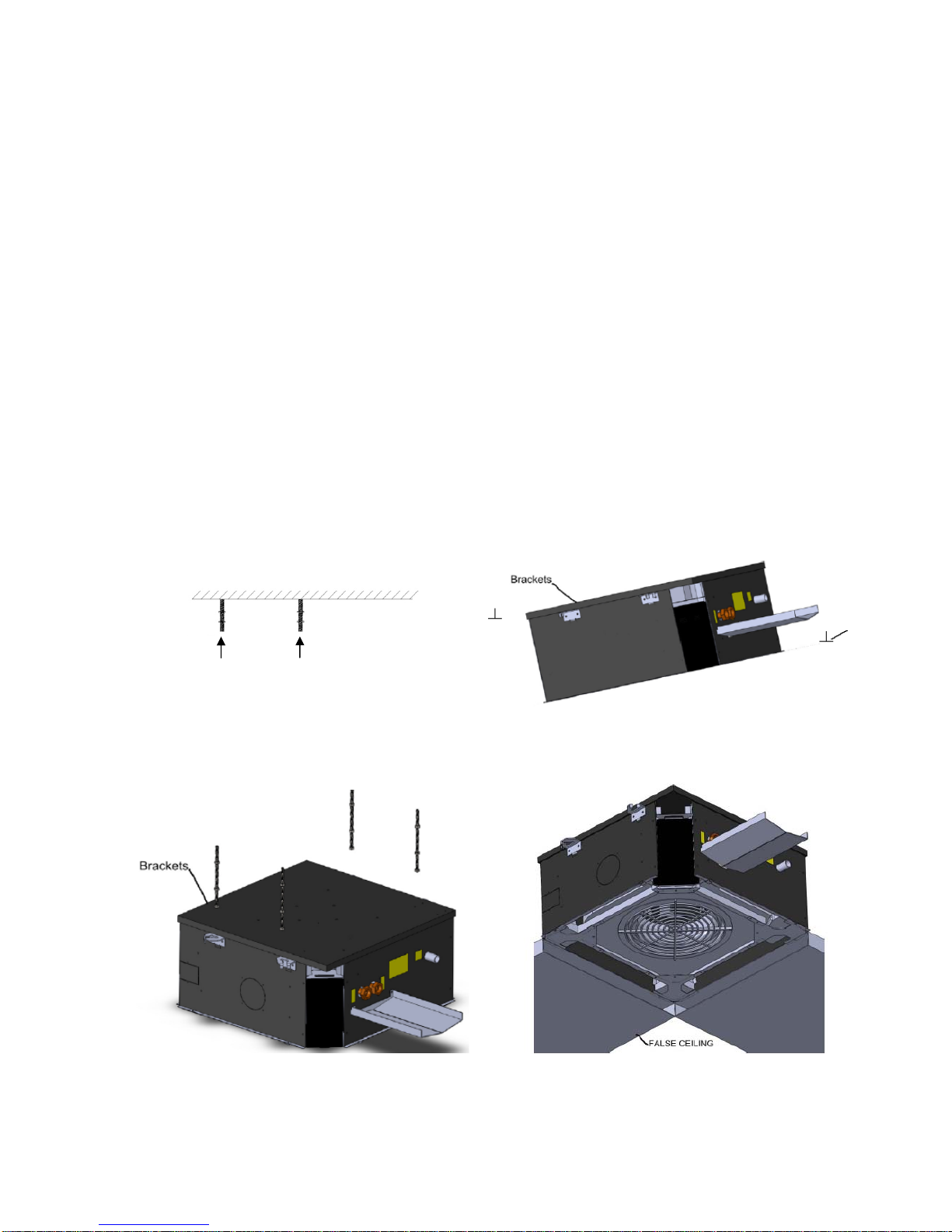

Fixation .............................................................................................................................................................. 3

Condensate drain .............................................................................................................................................. 7

4.FRESH AIR CONNECTIONS ....................................................................................................................... 8

5.HYDRAULIC CONNECTIONS ...................................................................................................................... 9

Instructions ......................................................................................................................................................... 9

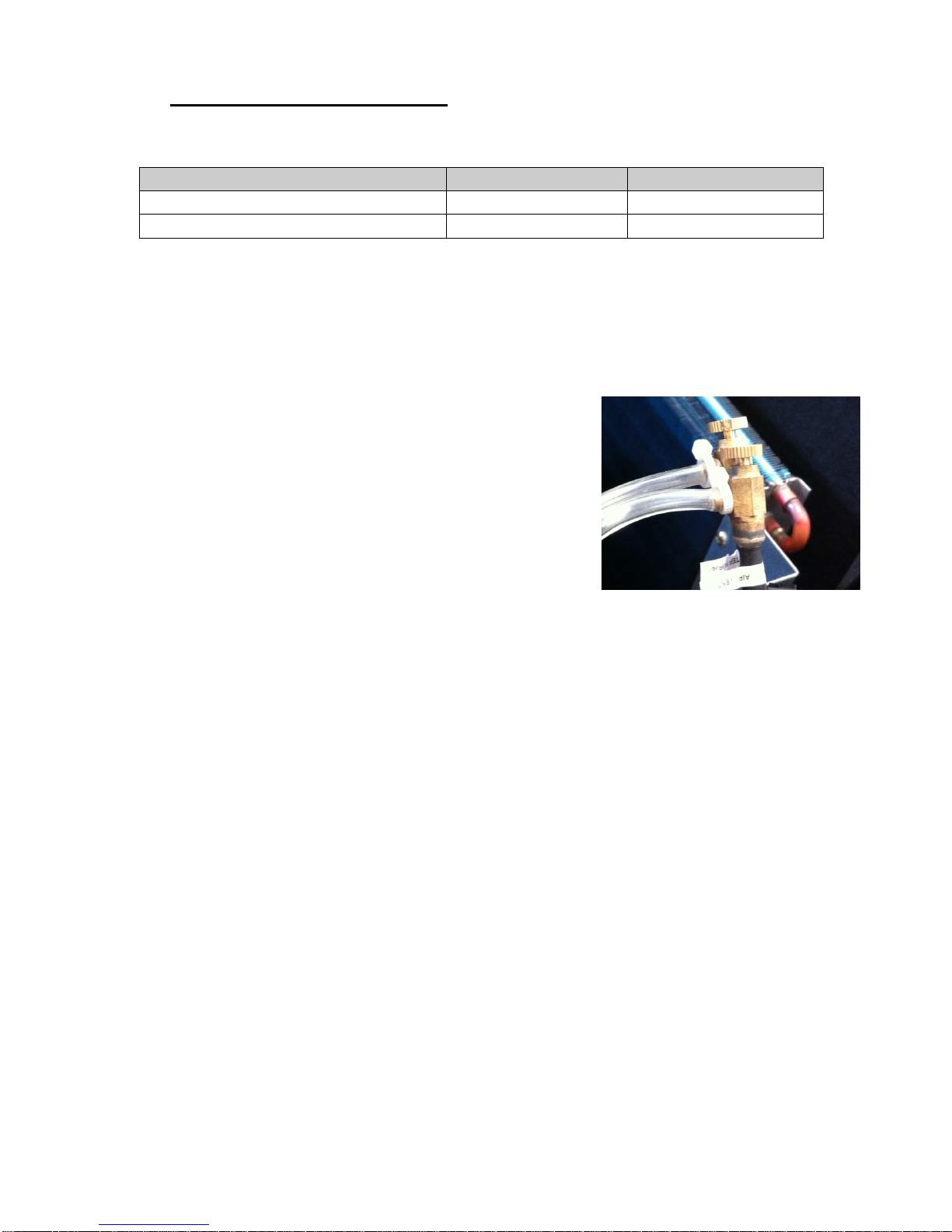

Control valves .................................................................................................................................................... 9

External Drain Pan ............................................................................................................................................ 11

6.ELECTRIC CONNECTIONS ........................................................................................................................ 12

Motor power ...................................................................................................................................................... 12

Electric power auxiliary heating resistor ........................................................................................................... 12

Electrical connections (4 Pipes) ........................................................................................................................ 13

Electrical connections (2 Pipes + Electrical heater) .......................................................................................... 14

7.BOX CONTROL ......................................................................................................................................... 195

Description ........................................................................................................................................................ 15

Control logic ...................................................................................................................................................... 16

8. LED INDICATION AND ERROR DESCRIPTION ....................................................................................... 17

9.SPEED CONTROL BOX .............................................................................................................................. 18

10.DIMENSIONS AND WEIGHT ...................................................................................................................... 19

11.START-UP ................................................................................................................................................... 21

12.MAINTENANCE ......................................................................................................................................... 262

Removing the internal components .................................................................................................................. 22

Fan motor replacement .................................................................................................................................... 23

Replacement control box .................................................................................................................................. 23

Condensate pump replacement ........................................................................................................................ 24

Replacing electrical resistance ......................................................................................................................... 25

Long shutdown periods ..................................................................................................................................... 25

User guide ........................................................................................................................................................ 25

13.SPARE PARTS .......................................................................................................................................... 266

To get all the air flow and acoustic performances, refer to the general catalogue and/or the BALI datasheet

(available on www.aircalo.fr)