© 2007 ALL RIGHTS RESERVED 3

INTRODUCTION

1POWER SYSTEM

2

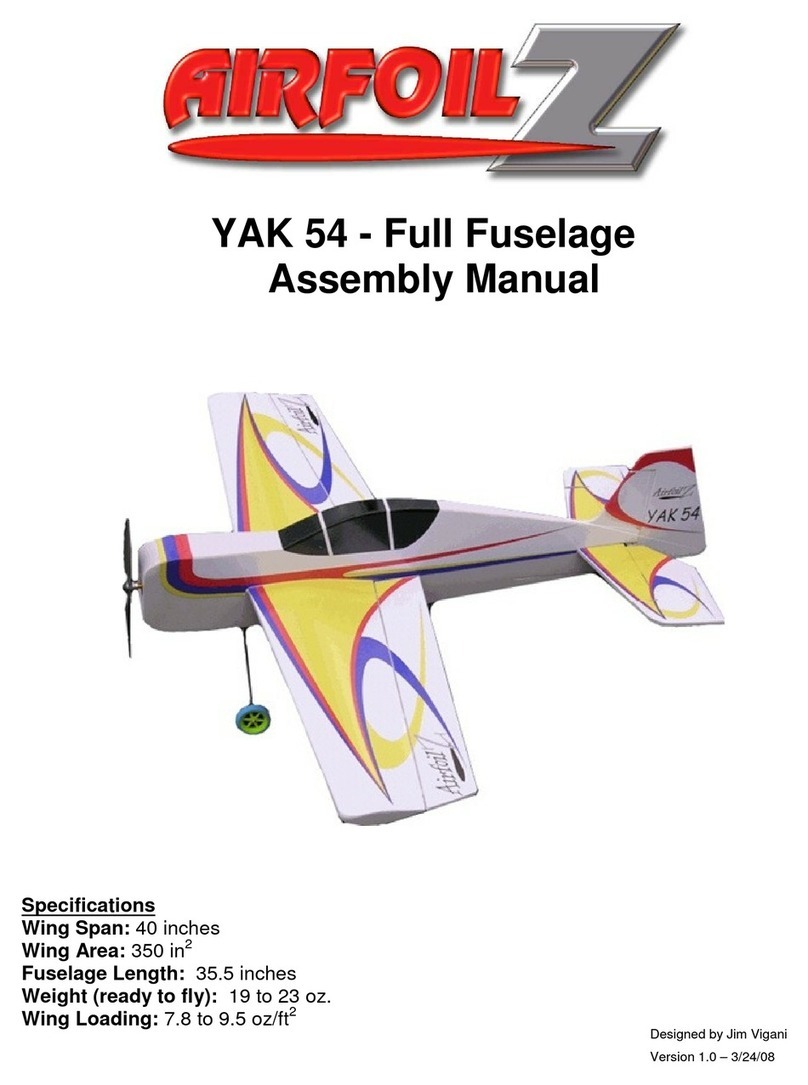

Thank you for choosing the AirfoilZ Yak54 airplane. We

have taken great care to provide a design and kit com-

ponents that, when properly assembled, will give you

a high quality model with outstanding performance.

While the assembly is not complicated, the quality and

ultimate performance of your model will depend a great

deal on the care you take while building. Please read

these instructions carefully and be sure that you under-

stand them before you start. Take care to assemble the

components as shown and in proper alignment.

This plane has been designed using a Hacker A20-20L

Brushless Motor with a Hacker X-20 Speed Controller and

Thunder Power 1320 mah, 3S Li-poly battery, turning an

APC, 10 x 4.7 Slow Flyer propeller. Other power systems

with similar capabilities can be used. Performance will

vary depending on the specic power system selected.

For information on alternate power systems please visit

http://www.airfoilz.com/forums.

ADDITIONAL ITEMS

3

In addition to the kit contents, we recommend having

the following building supplies on hand to complete the

kit assembly in accordance with this manual.

Foam safe (odorless) CA

Foam safe CA“Kicker”

Thin CA

Gorilla glue and/or 5 and 15 min epoxy

JB Weld

Double back tape or spray adhesive

Low tack masking tape (blue painter’s tape)

Sanding block with 100 grit sandpaper

Sanding stick or emery board (150 grit)

Craft Popsicle-size wooden sticks

Soldering iron and resin core solder

1/32 inch and 3/32 inch diameter drill bits

Exacto knife with #11 blade

Utility knife

Small square

36 inch ruler

Needle nose pliers

3/8 inch diameter brass tubing

½ inch diameter brass tubing

Dremel tool with abrasive cuto wheel

Diagonal cutting pliers

REQUIRED

Building Supplies

3.1

RECOMMENDATION

This radio-controlled model is not a toy and, if operat-

ed inappropriately, can cause serious bodily injury and

property damage. It is the buyer’s responsibility to as-

semble the kit correctly and to properly install the mo-

tor, radio, and all other equipment. The model must al-

ways be own in accordance with the safety standards

of the Academy of Model Aeronautics (AMA).

This model is designed to be fully 3D capable. While

it is reasonably simple to assemble, it is not intended

for the novice ier. Do not attempt to learn to y with

this model! If you are an inexperienced modeler, we

recommend that you get the assistance of an experi-

enced modeler to help you with the assembly and ini-

tial ights. There are many local clubs that can oer

help with assembly and ight instruction. Information

on local clubs may be found through the Academy of

Model Aeronautics (AMA) at www.modelaircraft.org.

The AMA has over 2500 chartered clubs throughout

the country.

We do not recommend the use of hot glue for mount-

ing components such as servos, control horns, receiv-

ers, or speed controls.

WARNING