© Copyright 2009 all rights reserved

3

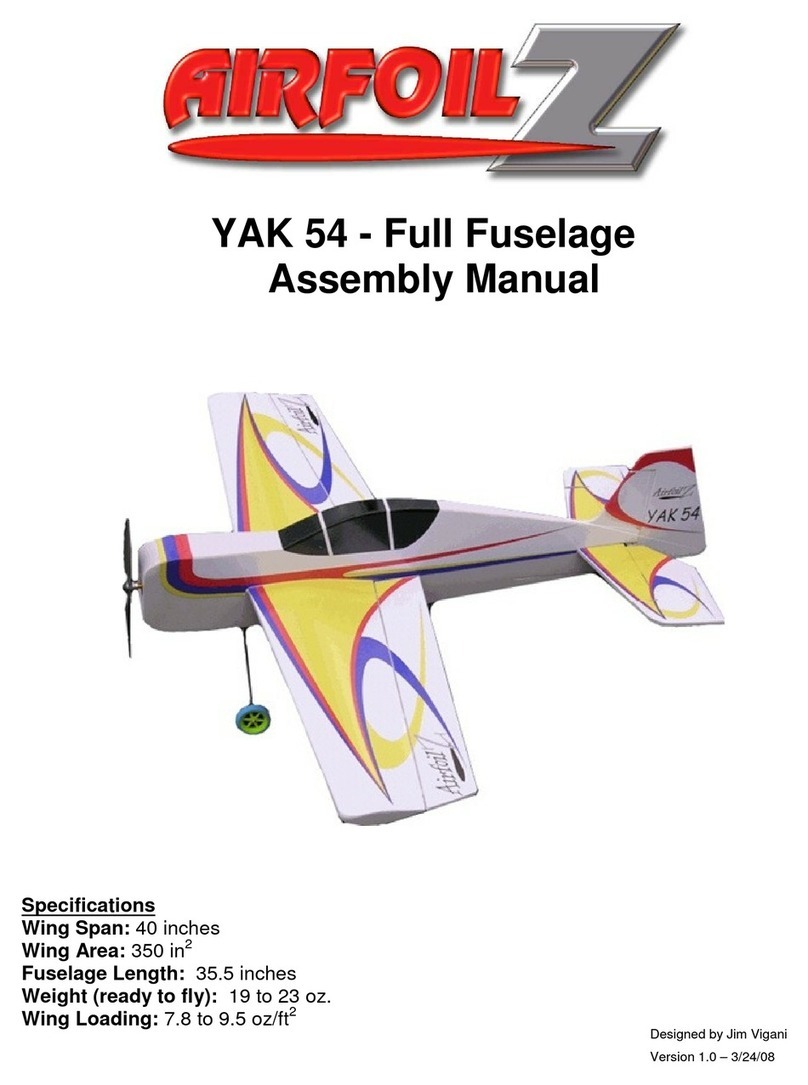

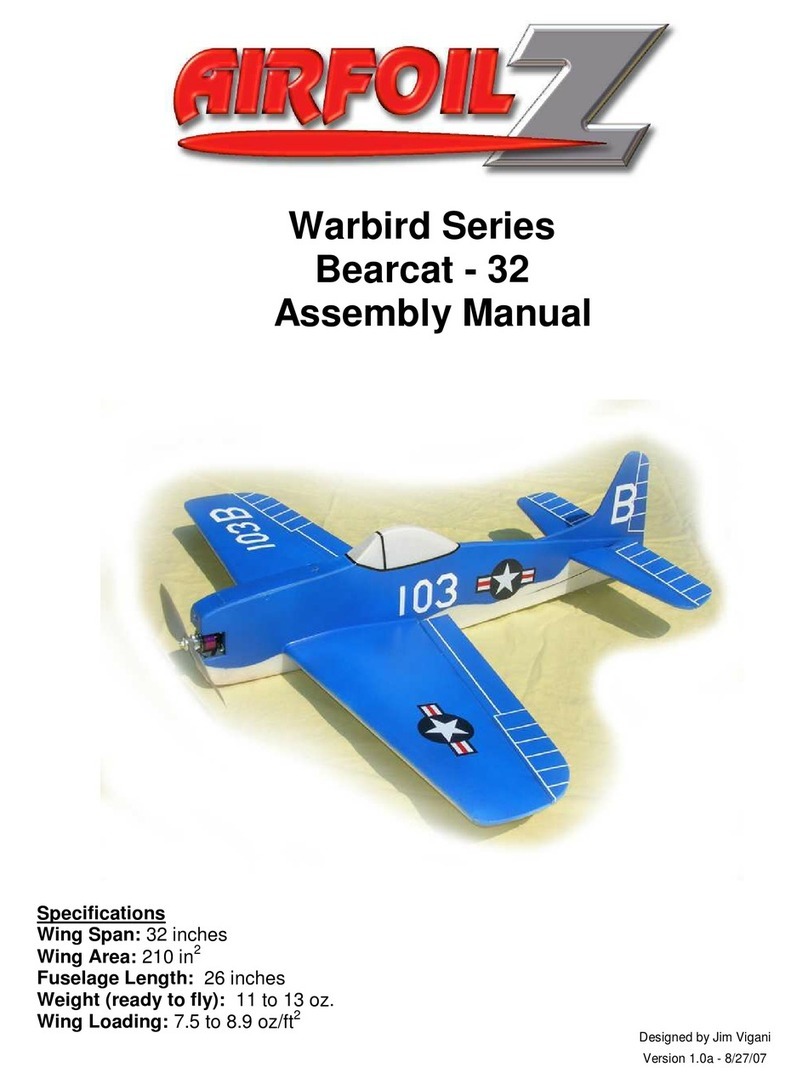

Introduction:

Thank you for choosing one of the AirfoilZ NX Profile Series airplanes. We have taken great care to

provide a design and kit components that, when properly assembled, will give you a high quality

model with outstanding performance. While the assembly is not complicated, the quality and

ultimate performance of your model will depend on the care you take while building. Please read

these instructions carefully and be sure that you understand them before you start. Take

care to assemble the components as shown and in proper alignment.

Please note that the material used for some of the parts shown may be

different in from those provided in the kit. The installation of these parts

is unaffected by the material change.

Warning

This radio-controlled model is not a toy and, if operated inappropriately can cause serious

bodily injury and property damage. It is the buyer’s responsibility to assemble the kit correctly

and properly install the motor, radio and all other equipment. The model must always be flown in

accordance with the safety standards of the Academy of Model Aeronautics (AMA).

This model is designed for high performance. While it is reasonably simple to assemble, it is not

intended for the novice flier. Do not attempt to learn to fly with this model! If you are an

inexperienced modeler, we recommend that you get the assistance of an experienced modeler to

help you with the assembly and initial flights. There are many local clubs that can offer help with

assembly and flight instruction. Information on local clubs can be found through the Academy of

Model Aeronautics. The AMA has over 2500 chartered clubs throughout the country. Information

on the AMA can be found at www.modelaircraft.org.

We do not recommend the use of hot glue for mounting components such as servos, control horns,

receivers or speed controls.

Recommended Power System:

This plane has been designed to use a 175 to 250 watt power system. Recommended motors

include the Common Sense E5 –L -13, Hacker A20-20L, Scorpion 2215-18, or AXI 2217-16. The

prototype was flown with the Common Sense E5-L-13. a 25-amp Pheonix ESC, and a 1500 mAh,

3S Li-poly battery with a APC 10x5Epropeller. Other power systems with similar capabilities can be

used. Performance will vary depending on the specific power system selected. For information on

alternate power systems please visit http://3dxhobbies.com or your local hobby shop.