The Airplane Factory

Manufacturing Organization DC-SBU-003-X-X-1

Service Bulletin Issue 1, 20/11/2015 Page no: 4

16. It should be noted that the ribs removed from the aircraft should be scrapped and never used on an

aircraft again.

17. Once the new part have been assembled with reference to the rib 601 & bracket assembly page, place

them in the fuselage as the previous parts were positioned.

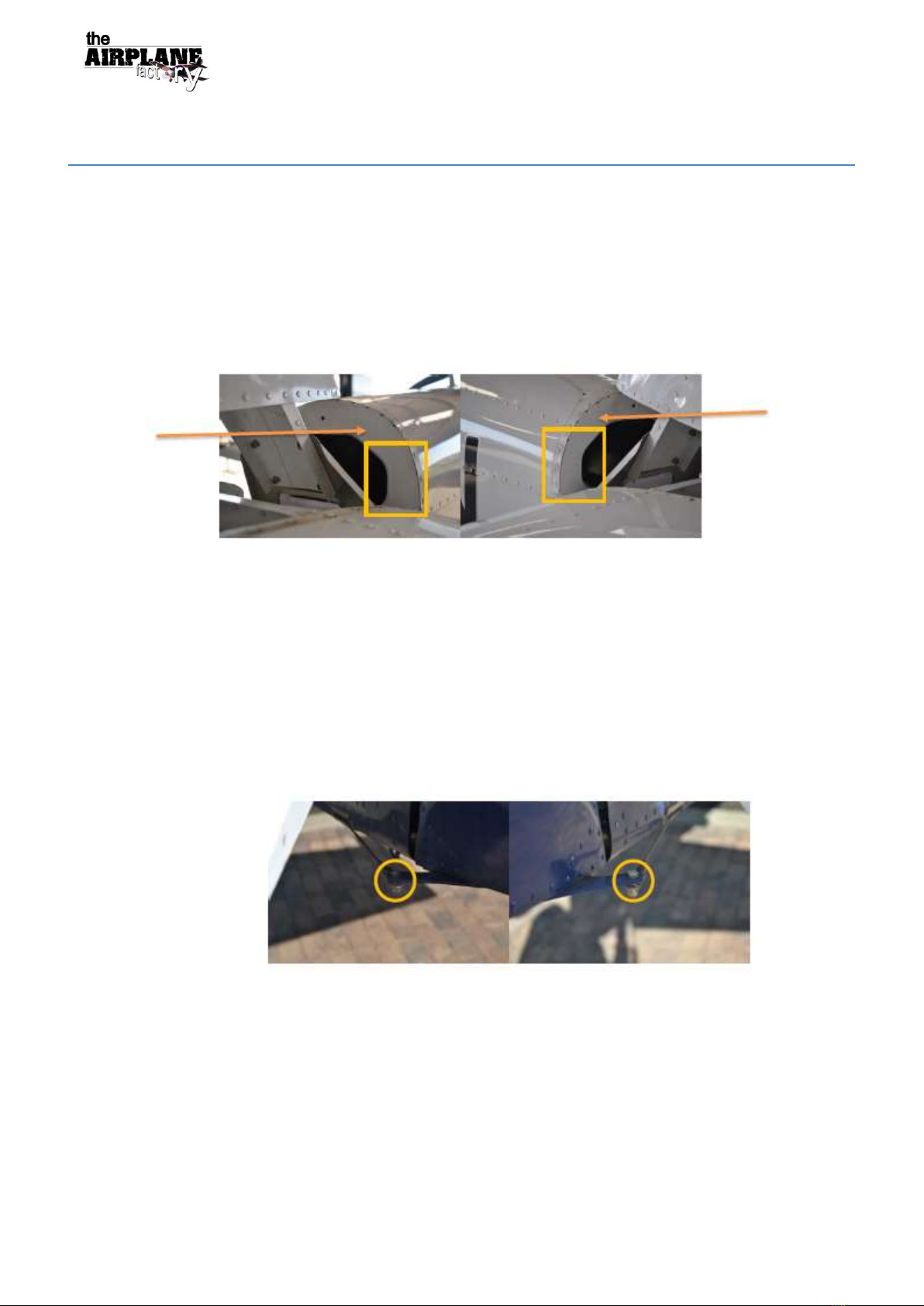

18. Using clecos, cleco every second hole of the rib and bracket to the side of the fuselage which has not had

the skin removed.

19. Place skin (4) onto the fuselage and cleco it in place by placing clecos in every second hole.

20. Rivet each hole with 3.2 mm domed aluminium rivets. It should be noted that with reference to the above

picture, the rivets in the red boxes should be rivets of 4 x 10 mm domed aluminium rivets, the exact place

of these rivets can be found with reference to the rib 601 & bracket assembly instruction page, and these

parts are labelled 3 & 4.

21. Remove all the clecos and rivet all the open holes where the clecos were. Ensure the correct rivets are

used in the correct places, refer to step 20.

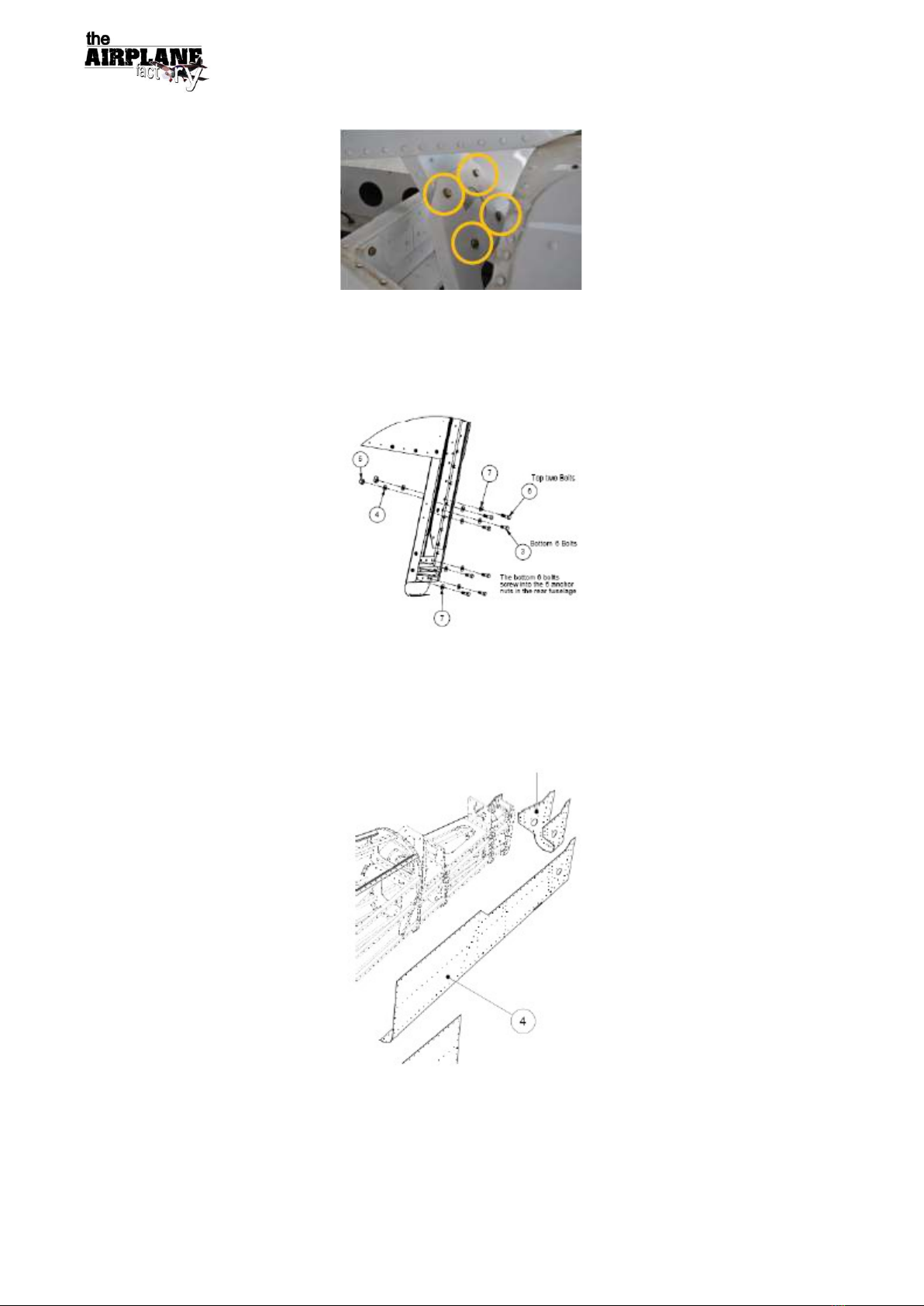

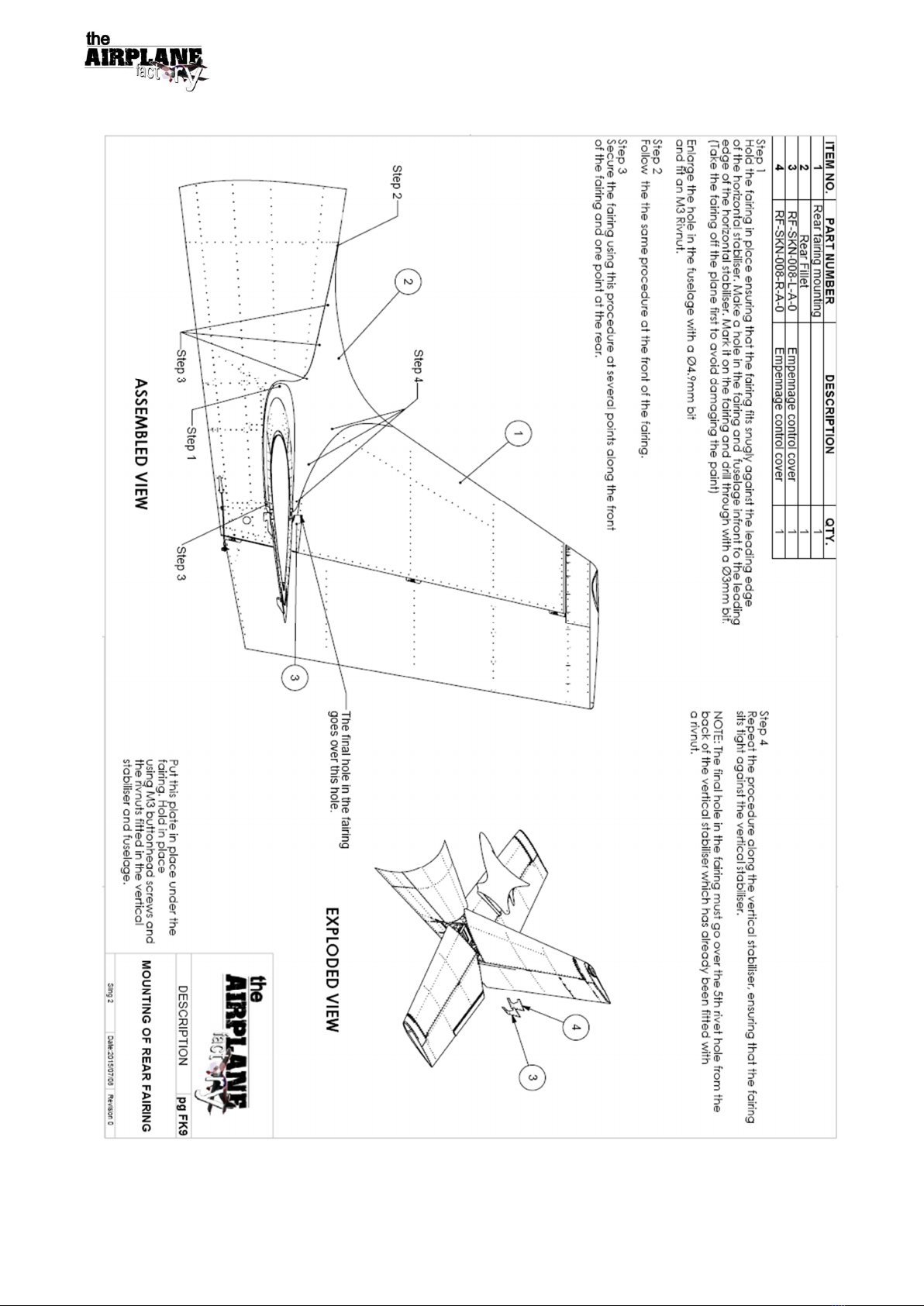

22. Attach the horizontal stabiliser to the fuselage by means of tightening all 8 of its bolts to the mounting

brackets of the fuselage. These bolts need to be torqued to a value of 2.0 – 2.7 NM or 1.475 – 1.991 ft.lb

and torque seal applied over all 8 of these bolts.

23. Attach the vertical fin by means of tightening all 12 bolts to the mounting brackets on the fuselage. These

bolts are to be torqued to the value of 2.0 – 2.7 NM or 1.475 – 1.991 ft.lb and torque seal applied over all

12 of these bolts.

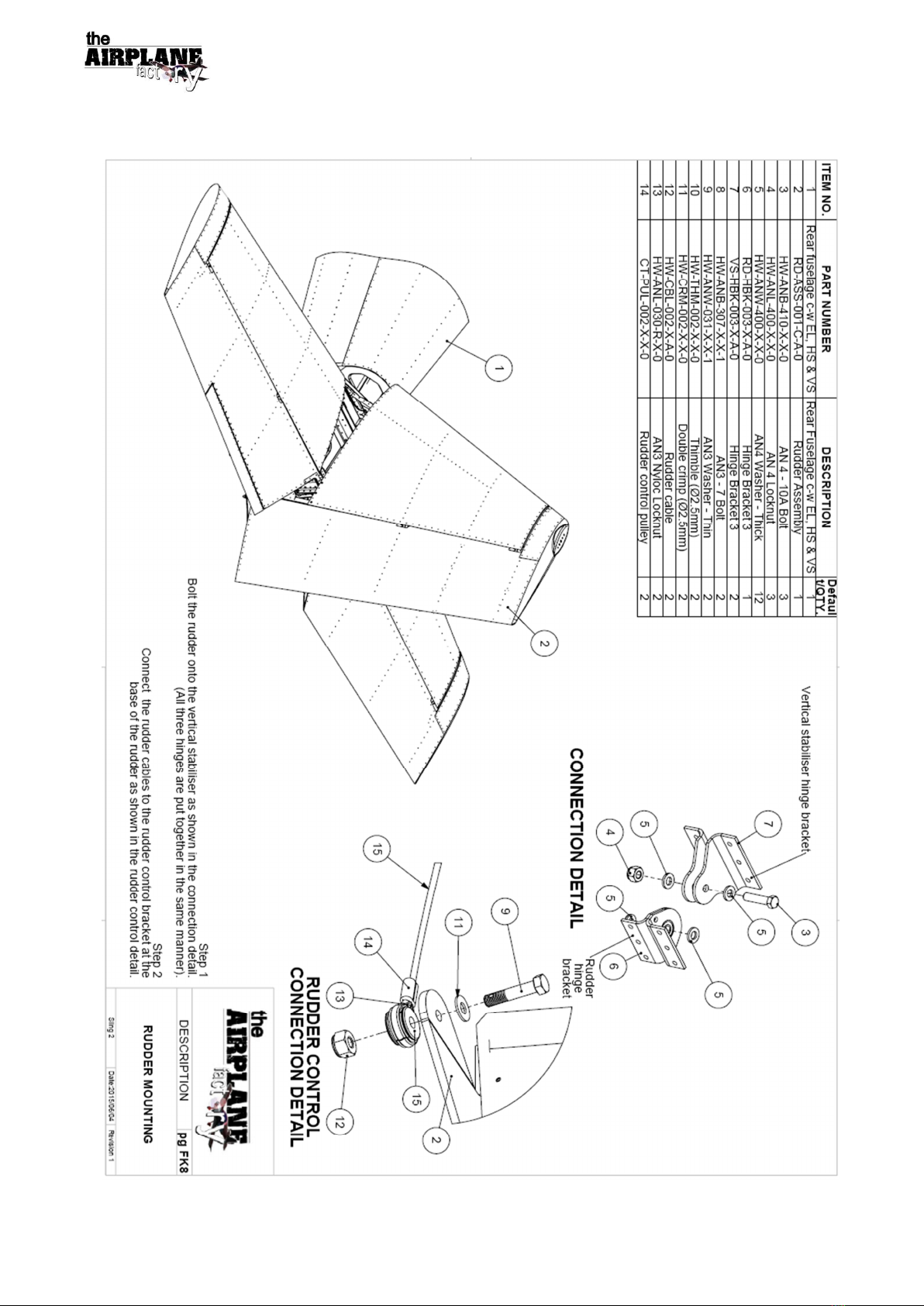

24. Attach the rudders by means of tightening all 3 bolts through the rudder hinges. These 3 bolts should be

torqued to the value of 2.0 – 2.7 NM or 1.475 – 1.991 ft.lb and torque seal applied to all 3 bolts.

25. Connect the strobe light wire and verify that the strobe is serviceable.

26. Using the two 3/8” spanners attach the rudder cables by means of tightening both bolts at the connection

points. These bolts need to be torqued to the value of 2.0 – 2.7 NM or 1.475 – 1.991 ft.lb and torque seal

applied over these bolts.

27. Attach the empennage fairing by means of tightening all the screws using a 2 mm Allen key.