4/8/2008R series service manual

PAGE OF 20

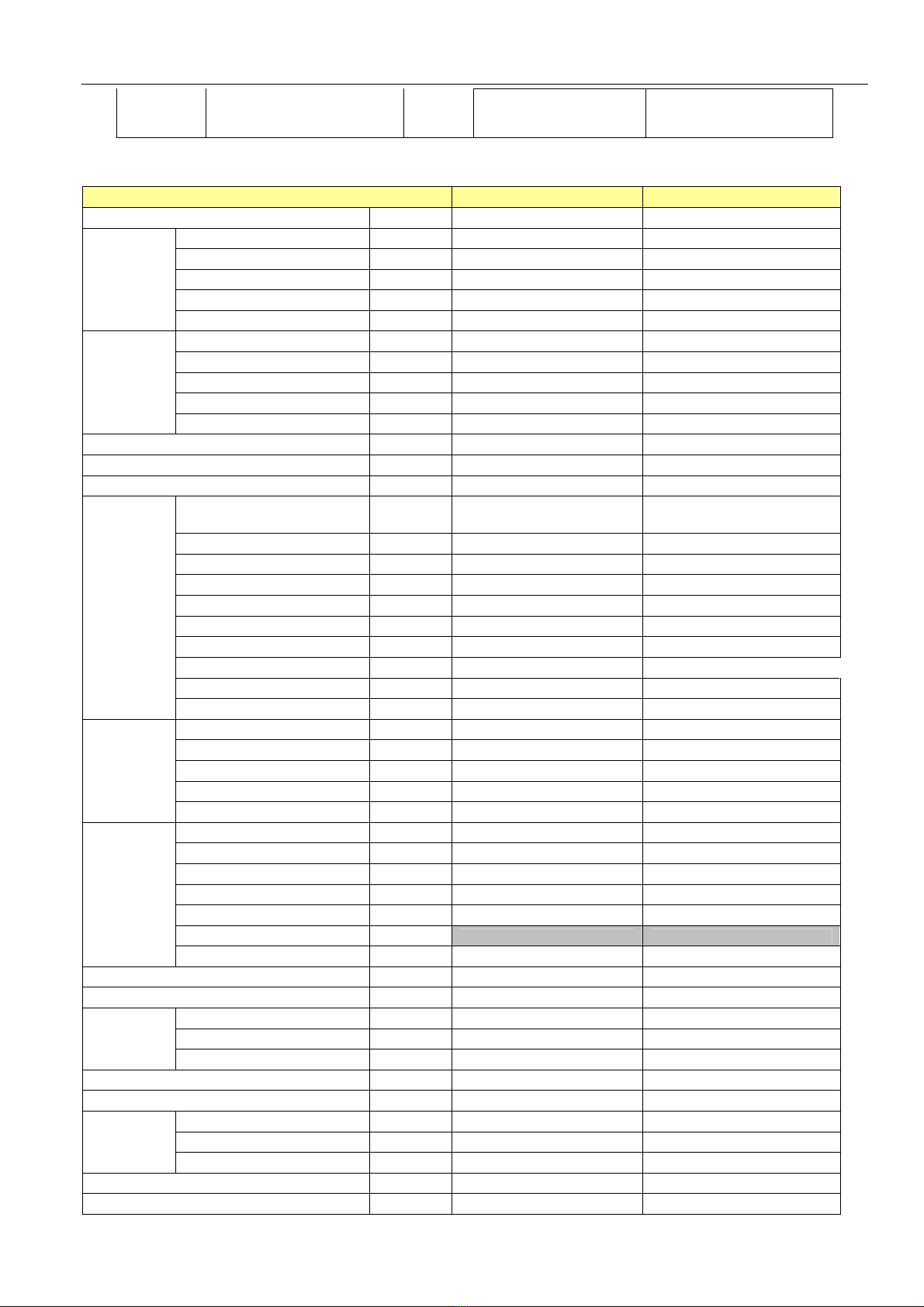

Thermostat t pe

Electronic control

Operation temp ℃ 17-30

Ambient temp ℃ 18~43(cooling); -7~24(heating)

Outdoor Model MSM-27HRN1 MSM-30HRN1

Power suppl Ph-V-Hz 1Ph,220-240V~,50Hz 1Ph,220-240V~,50Hz

Btu/h 27000 30000

W 7913 8792

Input W 2570 2880

Rated current A 13.1 13.7

Cooling

EER w/w

3.03 3.02

Btu/h 30000 34000

W 8792 9965

Input W 2700 3070

Rated current A 13.3 14.2

Heating

EER w/w

3.22 3.22

Max. input power W 3600 3600

Max. current A 16.6 16.6

Starting current A 31.8 31.8

Model

PA200X2CS-4KU1;

PA145X2C-4FT

PA200X2CS-4KU1;

PA145X2C-4FT

T pe

ROTARY ROTARY

Brand

TOSHIBA TOSHIBA

Capacit Btu/h 16791+12014 16791+12014

Input W 1670+1200 1670+1200

Rated current(RLA) A 7.81+5.6 7.81+5.6

Locked rotor Amp(LRA) A 57+57 57+57

Thermal protector

Internal Internal

Capacitor uF 45+35uF/370VAC 45+35uF/370VAC

Compressor

Refrigerant oil ml 750+480 750+480

Model

YDK50-4G1 YDK50-4G1

Brand

Welling Welling

Input W 200 200

Capacitor uF 4uFx2 4uFx2

Outdoor fan

motor

Speed r/min 1150 1150

a.Number of rows

2 2

b.Tube pitch(a)x row pitch(b) mm 25.4x24 25.4x24

c.Fin spacing

mm 1.7 1.7

d.Fin t pe (code)

H drophilic aluminium H drophilic aluminium

e.Tube outside dia.and t pe mm Ф9.53, Innergroove tube Ф9.53, Innergroove tube

f.Coil length x height x width mm 813X812X44 813X812X44

Outdoor coil

g.Number of circuits

3/3 3/3

Outdoor air flow m3/h 3200 3200

Outdoor noise level dB(A) 58 58

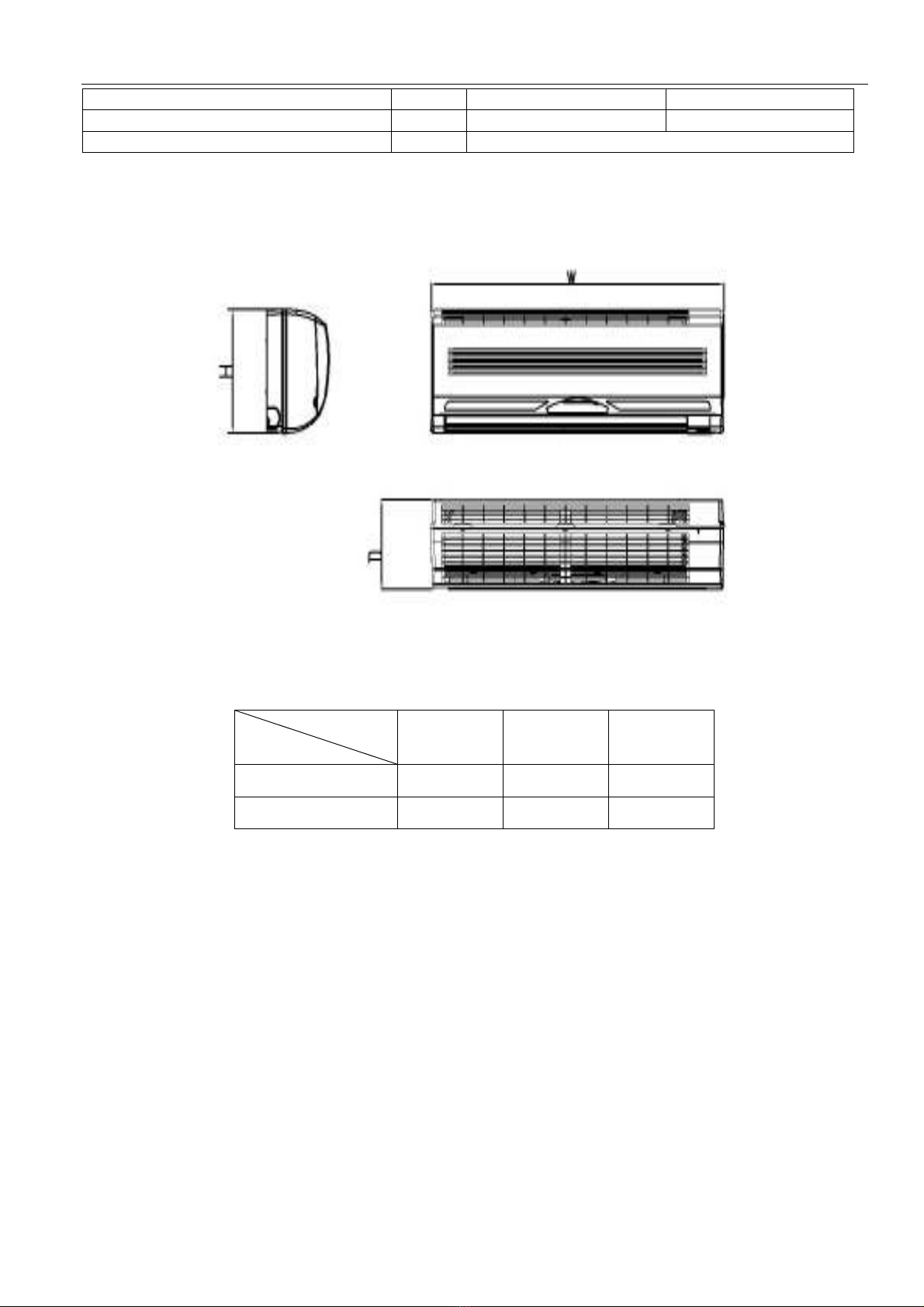

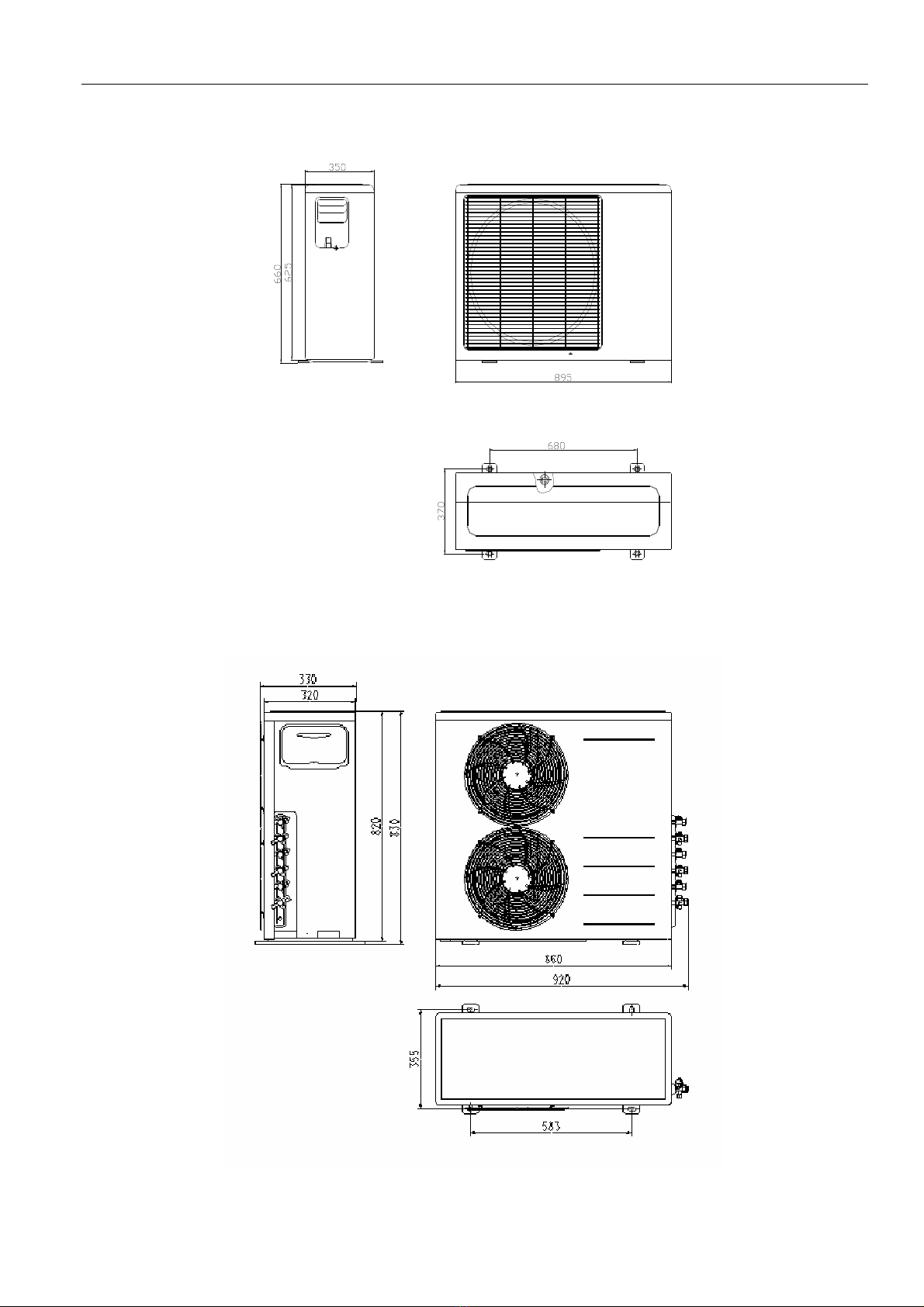

Dimension(W*H*D) mm 860X830X330 860X830X330

Packing (W*H*D) mm 1000X985X425 1000X985X425

Outdoor unit

Net/Gross weight Kg 81/90 81/90

Refrigerant t pe R410A g 1550+1150 1550+1150

Design pressure(Hi/Lo) MPa 4.4/2.0 4.4/2.0

Liquid side/ Gas side mm(inch) Ф6.35/Ф9.53

Ф6.35/Ф12.7

Max. refrigerant pipe length m 15 15

Refrigerant

piping

Max. difference in level m 10 10

Connection wiring

No

Plug t pe

No