4

Safety

!Attention

Payattention to the

aeration condition

to avoid anoxic

symptom.

It isnot allowed to put anyheating

apparatusunderthe indoorunits,forthe

heat maycausedistortion of theunits.

Flammableapparatusshouldnot beplaced

inthe place where the airconditionerwind

could reachdirectly, orincomplete burning

of theapparatus

maybe caused.

3-minute protection

Toprotect the unit, compressorcan be

actuated with atleast 3-minute delayafter

stopping.

Close the window to avoid outdoorair

gettingin.

Curtainsorwindow

shutterscan be put

down to avoid the

sunshine.

Do not put flammable spraycloseto the air

conditioner.

Don’t inject flammablespraytowardsthe

airconditioner, which may

cause fire.

Stopping fan rotation

Theunit which stopsoperating willactuate

the fan fora 2-8 min swing every30-60

minutesforprotecting the unit while other

indoorunit arein the operating state.

Powershould be cut off when theair

conditioneris left unused fora long period.

Powerwill be consumed if the air

conditioneris not powered off. The power

switch of the outdoorunit switch should be

powered on 12 hoursin advance before

operation to protect the unitaftera long

period ofstorage.

Defrosting during heating

To improve the heating effect, the outdoor

unit willperformdefrosting automatically

when frost appearson the outdoorunit

during heating (approximately2-10 min).

During defrosting, the fan of the indoorunit

runsata low speed orstopswhile thatof

the outdoorunit stopsrunning.

Do not use waterheaterorlike next to the

indoorunit and the wired controller.

Water/powerleakage orshort circuit may

happen if the steamgenerating apparatus

isworking nextto machine.

Use the fuse with propercapacity.

Metalwiresand copperwires, etc.,

maycause fire orotherfaults.

It cannot be used forthe preservation of

food, living creature, precise instrument

and artworks, etc, otherwise damage

mayoccur.

Plantsand animalsshould not be put to

the placewhere wind of the airconditioner

blowsdirectly, otherwise damage to

themmaybe caused.

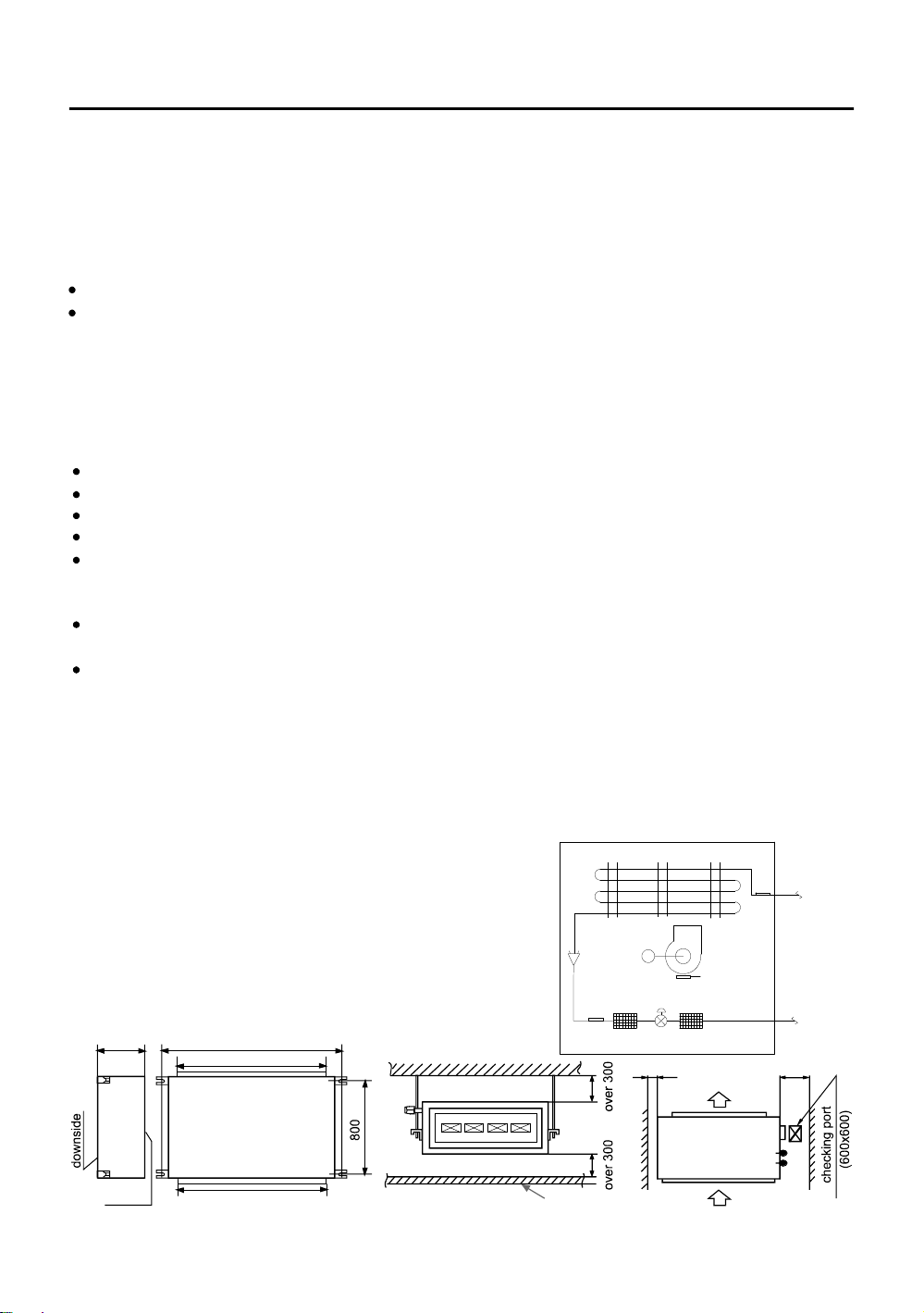

Checkthe mount table

of theairconditionerfordamage fora long

period ofoperation.

If placed on the damaged table, the

unit maydrop down causing damage.

Thisappliance isnotintended foruse by

persons(including children)with

reducedphysical, sensoryormental

capabilities, orlackofexperience and

knowledge, unlesstheyhave been given

supervision orinstruction concerning use

of the appliance bya person responsible

fortheirsafety.

Cleaning the unit with watermaycause

electricshock.

Do not touch the switch withthe wet

hand to avoid powershock.

Stop running and switch off the manual

powerswitch when cleaning the

unit.

During the operation of the controlunit,

don’t switch off the manualpowerswitch

and the controllercan be used. Please do

not pressthe liquid crystalzone of

controllerto prevent damage