AHE00060EN 1904

4

Alfa Laval is a trademark registered and owned by Alfa Laval Corporate AB.

Alfa Laval reserves the right to change specification without prior notification.

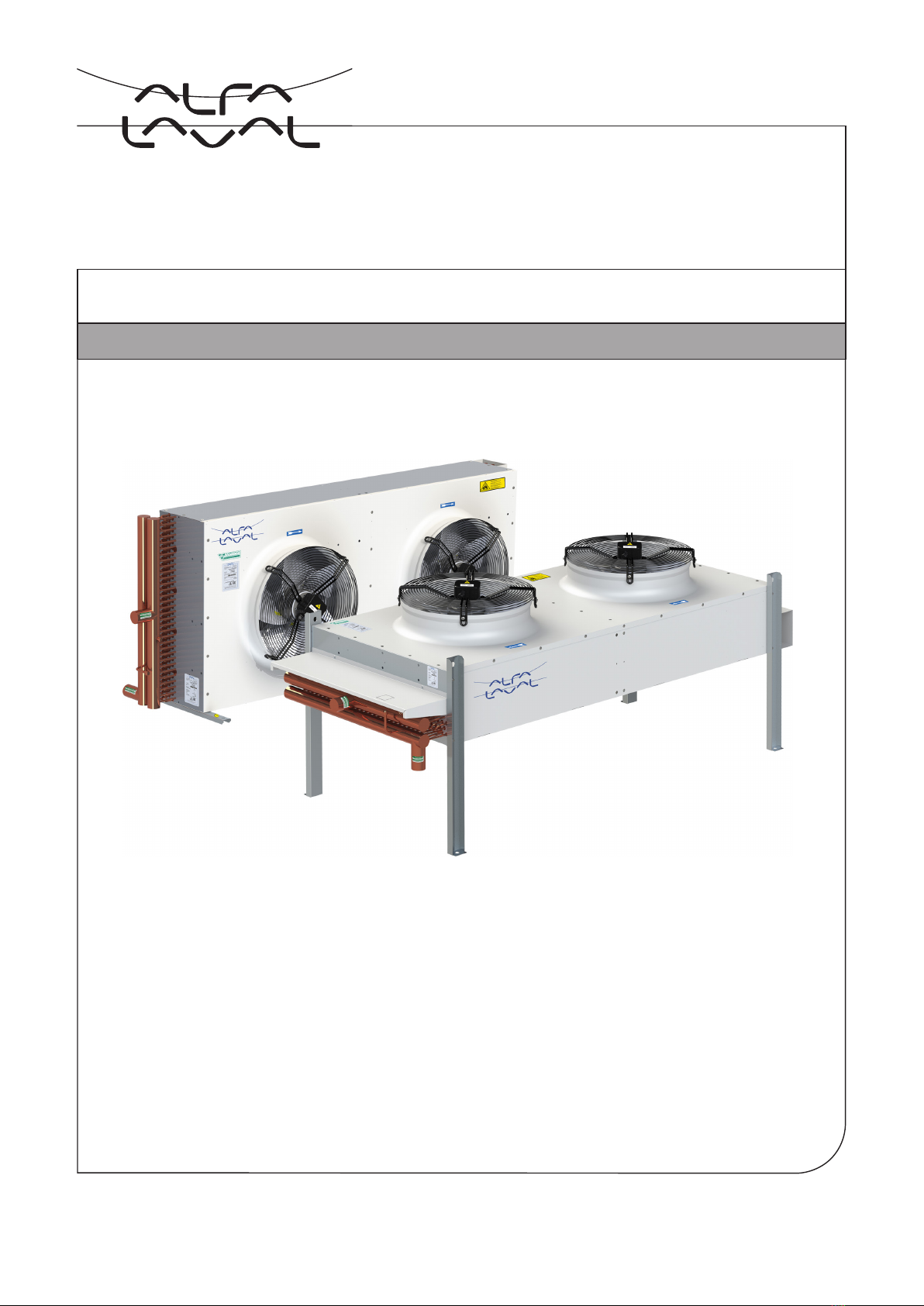

2 Product description

2.1 General information and application

AlfaBlue Junior is a competitive condenser (AG) and gas cooler (XG) line that offers excellent per-

formance, allowing easy installation on site and an outstanding integration with other components.

High efficient fan motors combine excellent sound characteristics and low energy consumption.

AlfaBlue Junior AG condensers can be used in commercial refrigeration and HVAC installations.

AlfaBlue Junior XG gas coolers have been specifically designed for CO2refrigerant systems.

• AG condensers suitable for all HFO/HFC refrigerants.

• AG capacity range (SC2): 5.6 up to 260 kW.

• XG capacity range: 3.2 up to 230 kW

(air temp. = 35°C, CO2 at 90 bar, gas temp. in/out = 120/38°C)

2.2 Standard configuration

Finned coil:

Innovative coil design manufactured from Cu tubes (K65 for XG) and aluminium turbo fins.

Standard fin spacing 2.1 mm. Each heat exchanger is leak tested with dry air (nitrogen for XG) and

finally supplied with a nitrogen pre-charge.

Model Design pressure Test pressure

AlfaBlue Junior AG(H) 33 (45) bar 47 (65) bar

AlfaBlue Junior XG 120 bar 172 bar

Construction:

Patented coil frame design allowing thermal expansion and offering protection against vibration.

Corrosion resistant casing material, powder coated RAL9002. Separated fan sections.

Fans:

High efficiency AC or EC fans and low power consumption. Available in 3 fan diameters 350, 500

and 630 mm, different power supplies (230/50-60/1, 400/50/3, 480/60/3) and four noise levels.

Protection class IP 54 according to DIN 40050.

AC motors are fitted with integrated thermo contacts to provide reliable protection against thermal

overload (terminals in the box).

2.3 Options

• Switch on/off (SW)

• Connection box for electrical power connection (CB)

• Fan speed control 230/1 and 400/3 (FP)

• Coil options:

- Epoxy coated aluminium fins (EP)

- Seawater resistant aluminium AlMg fins (SWR)

- Copper fins (CU)

- F-coat treatment (FC)

- Industrial fins (IF)

- Fin spacing 2.5 mm. Other fin spacings on request.

• Vibration dampers (VD)

• End covers (CV)

• Mounting feet kit for vertical airflow

• Stainless steel header tubes for on-site welding connections (XG only)