Contents

1 Important information..............................................................................3

1.1 Disclaimer..................................................................................................................................... 3

1.2 Intended use................................................................................................................................. 3

1.3 Where to find product information................................................................................................3

2 Product description................................................................................. 4

2.1 General information and application.............................................................................................4

2.2 Standard configuration..................................................................................................................4

2.3 Options..........................................................................................................................................5

2.4 Code description...........................................................................................................................5

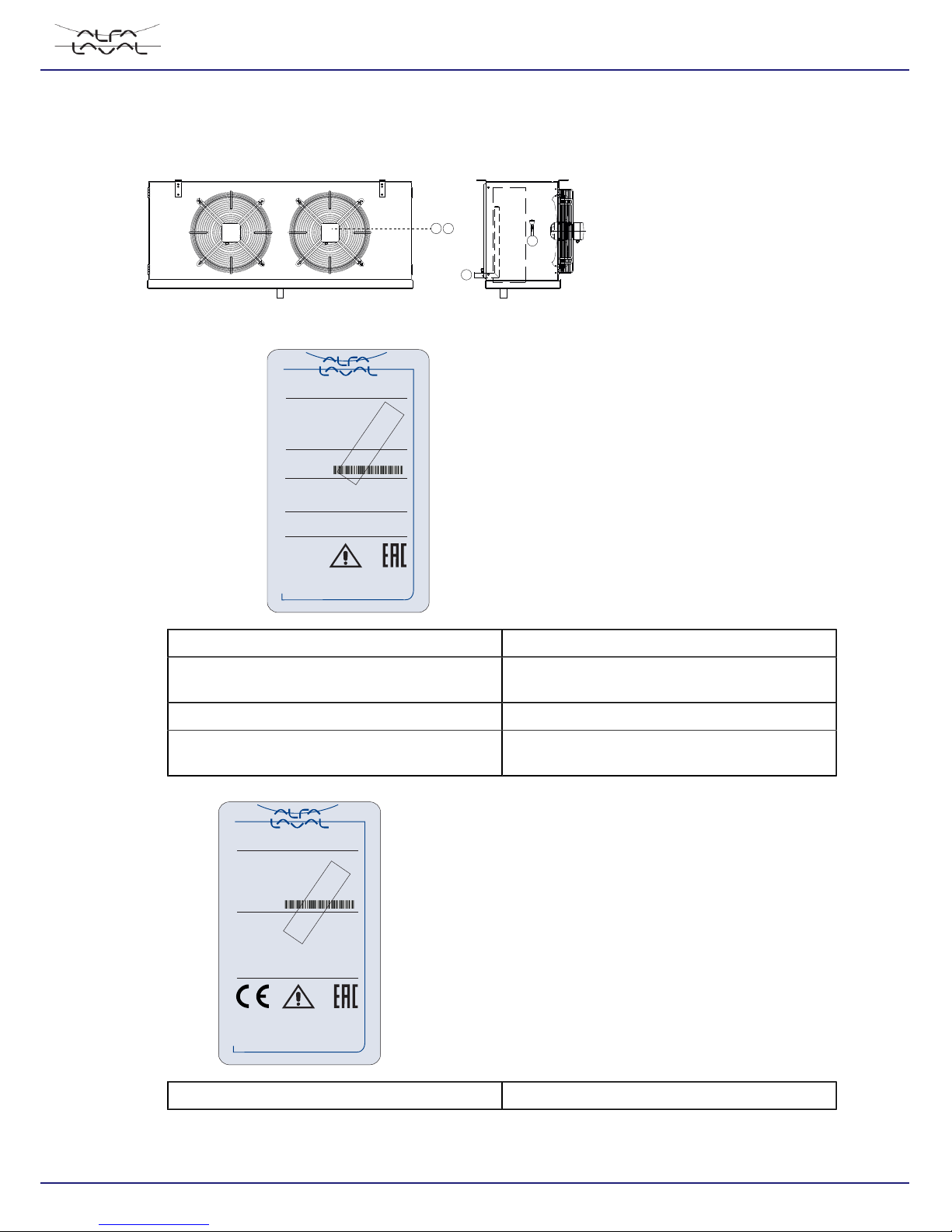

3 Product labels.......................................................................................... 7

4 Unpacking and lifting............................................................................ 10

4.1 Unpacking................................................................................................................................... 10

4.2 Lifting...........................................................................................................................................12

5 Installation...............................................................................................15

5.1 Mounting dimensions..................................................................................................................15

5.2 Mounting bracket........................................................................................................................ 17

5.3 Technical spaces........................................................................................................................ 18

5.4 Refrigerant connections..............................................................................................................19

5.5 Hotgas connection (optional)......................................................................................................19

5.6 Drain line.....................................................................................................................................20

5.7 Electrical connections................................................................................................................. 21

5.7.1 Electrical connections 1-phase AC fan motors.............................................................22

5.7.2 Electrical connections 3-phase AC fan motors.............................................................23

5.7.3 Electrical connections 1-4 EC fan motors 1-phase (2-speed, CC250 only).................. 24

5.7.4 Electrical connection for 1-4 EC fan motors 1-phase with 0-10V speed regulation..... 25

5.7.5 Electrical connection for 1-4 EC fan motor 3-phase with 0-10V speed regulation...... 27

5.7.6 Electrical connection for electric defrost CC400 & CC500........................................... 28

5.7.7 Electrical connection for electric defrost CC250 & CC350........................................... 29

5.7.8 Electric defrost capacities............................................................................................. 29

6 Maintenance............................................................................................33

6.1 Fan replacement.........................................................................................................................33

6.2 Driptray........................................................................................................................................33

6.3 Side covers................................................................................................................................. 34

6.4 Coil heater elements replacement..............................................................................................34

6.5 Driptray heater elements replacement....................................................................................... 35

7 Spare parts............................................................................................. 37