Allegro A89301 User manual

User Manual

A89301 Application Note

UM-A89301 February 27, 2019

Summary

This application note provides step-by-step instructions on how to use the A89301 Evaluation Board to program the Allegro

A89301 motor controller IC. In addition, this document contains feature descriptions and detailed circuit descriptions that are

not shown in the datasheet.

Table of Contents

Summary ............................................................................ 1

Step-by-Step Instructions ...................................................... 2

Step 1: Evaluation Board Connections................................. 2

Step 2: Launch the GUI ..................................................... 3

Step 3: Load saved parameters, if previously saved .............. 5

Step 4: Configure the basic parameters ............................... 6

Step 5: Start the motor....................................................... 7

Step 6: If motor does not move at all ................................... 8

Step 7: If motor shakes a little and stops.............................. 9

Step 8: If motor spins more than 5 cycles and stops ............ 10

Step 9: While the motor is spinning, go to the Status page;

click ‘Read Status’..........................................................11

Step 10: Adjust the motor inductance ................................ 12

Step 11: Fine tune the general parameters......................... 16

Step 12: PID Parameters ................................................. 17

Step 13: Startup Mode and Startup Settings....................... 18

Step 14: Lock detect parameters....................................... 20

Step 15: Speed control mode ........................................... 21

Step 16: Other settings .................................................... 22

Step 17: MOSFET CISS settings (CISS tab)....................... 25

Step 18: Save the settings and write into the EEPROM ....... 26

Default values of Allegro-only bits ..................................... 27

Note 1. How to determine the number of poles ................... 28

Note 2. Testing the IPD performance ................................. 29

Note 3. Debugging the lock detect feature.......................... 31

Note 4. Testing Motor Startup ........................................... 33

Other Operating Features of A89301 .................................... 34

Motor Operation Status Readback .................................... 34

I2C Hardware Connection ................................................ 35

OCL and OCP ................................................................ 35

OCP Masking Time and Filtering Time ............................... 35

Bus Current vs. Q-Axis Current......................................... 36

Gate Driver .................................................................... 36

Current Limit Level Ramping Up With Speed...................... 36

Charge Pump Capacitor Selection .................................... 37

2

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

STEP-BY-STEP INSTRUCTIONS

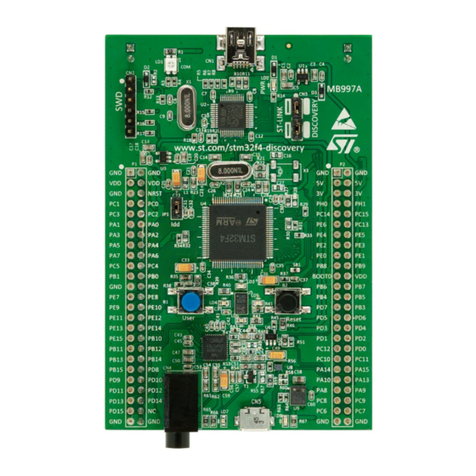

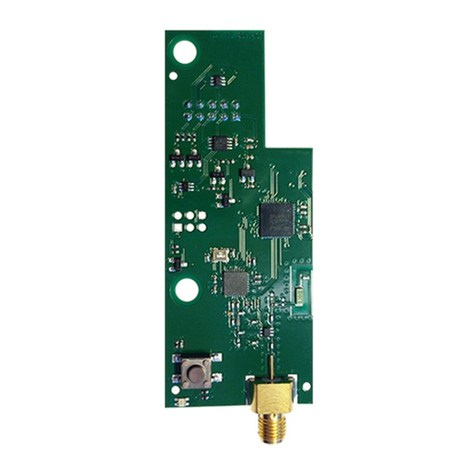

Step 1: Evaluation Board Connections.

B. Connect

power cables to

VBBIN and GND

A. Connect USB

cable to computer

C. Set the switch

to U1 PROG E. *Do NOT

connect motor

phases

SA,SB,SC yet

* The default sengs in the A89301 may

not be appropriate, which could cause

damage to the IC or motor. Sengs should

be veried before connecng a motor.

F. Turn on power

(to rated voltage)

D. Set JMP2 to

upper posion

3

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 2: Launch the GUI.

4

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 2: Launch the GUI. (continued)

B. If you see this error message,

install the USB to I2C chip driver

(FTDI D2XX). Check USB cable

connecon.

C. Make sure the power supply is

ON, and the switch is set to ‘U1

PROG’.

D. Try talking to the IC again. (As I2C_SDA

is shared with funconal mode FG pin, it

is possible the rst aempt failed because

the FG is pulled low).

To guarantee this won’t happen again in

the future, disable the FG funcon:

5

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 3: Load saved parameters, if previously saved.

Device parameters can be saved to a file. If a file for this (or similar) application has been created, open that file. Verify the Allegro-

only bits in the file are their default values.

B.

C.

E. F.

A.

D.

6

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 4: Configure the basic parameters.

Note: These numbers do not need to be very accurate; use the best estimation. There is fine tuning later in the process.

The number of pole pairs. For example,

12 pole motor: input 6 pole pairs.

See NOTE 1 to determine the number of poles.

The supply voltage that motor will be

working at. For example:

•Computer fan, 12 V power supply:

input 12 V.

•Supply voltage speed control, range

8 V to 24 V: input 24 V.

•Lithium baery system, voltage

11.1 V to 12.6 V: input 12 V.

Expected motor speed at ‘Rated Voltage’,

normal load condion, and 100% control

demand.

For example, pedestal fan, 1300 rpm with

blades and 1450 rpm without blades:

input approximately 1300 rpm.

Motor operaon current under ‘Rated

Voltage’, with normal load condion.

Rated Voltage, Rated Speed, and Rated

Current must be consistent.

Motor phase to center tap resistance,

measure phase to phase R and divide by

two.*

*Be sure to use an accurate mmeter. A ber oon may be to

apply a current through the motor, measure voltage across it, and

calculate resistance.

In the “Advanced” page, there is a

parameter defining the current sensing

resistor value. Program this value

appropriately.

7

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 5: Start the motor.

A. Connect motor phase A, B, and C.

B. Keep ‘Set speed demand via I2C’ checked.

C. Select the speed demand to 50%, and click Toggle Run/Stop.

The motor should start spinning.

If it does, go to step 9.

If not:

Doesn’t move at all,

go to step 6.

Shook a li�le bit

then stopped, go

to step 7.

Spun more than 5

cycles and stopped,

go to step 8.

8

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 6: If motor does not move at all:

A. Look at the LED indicator

connected to the Fault pin,

and follow the fault table to

determine the root cause.

B. If the LED is o, connect a current probe and

voltage probe to the motor outputs and check

if there is any current / voltage output to the

motor phase. If there is voltage but no current,

check motor phase connecons.

C. If the fault indicator LED is showing the “zero speed demand”, double

check the I2C speed demand seng is correct.

D. Toggle Run/Stop to retry startup.

9

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 7: If motor shakes a little and stops:

B. If it is OCP, check the phase output

wire connecons.

C. Otherwise, it is likely lock

detecon. If so, lower/slow down

the acceleraon seng. Note there

are two acceleraon ranges.

D. Toggle Run/Stop to retry the startup.

A. Look at the LED indicator

connected to the Fault pin,

and follow the fault table to

determine the root cause.

10

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 8: If motor spins more than 5 cycles and stops:

B. The problem is likely lock detec�on. If so,

go to the Standby / Protec�on page and

disable all the lock detect features.

C. Toggle Run/Stop to retry the startup.

A. Look at the LED indicator

connected to the Fault pin,

and follow the fault table to

determine the root cause.

D. One by one, enable each lock detect

feature to determine which is the cause of

the fault and which can be re-enabled.

11

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 9: While the motor is spinning, go to the Status page; click ‘Read Status’.

A. While the motor is spinning, go to the Status page. Click ‘Read Status’.

B. The system diagnos�cs

func�on will show you IC

temperature, motor

speed, supply current,

phase current, and supply

voltage. Compare the

supply current and voltage

data with the result

showing on the power

supply.

C. The Control demand is the amplitude that is

commanded (it should match the I2C speed demand

value). The Amplitude command is the actual

amplitude provided to the motor phase. If the

command is less than the demand, it is because of the

current limit. This problem is solved in Step 11.

12

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 10: Adjust the motor inductance.

A. Motor inductance is difficult to measure—it

varies with opera�on frequency, phase

current (satura�on), and also with the rotor

posi�on. Thus, A89301 provides an easy

method to adjust the inductance value and

achieve the best efficiency.

B. While the motor is spinning, connect a current probe to phase A, and connect a

voltage probe to phase A.

C. Enable the open window which is a debug

func�on. Remember to disable the

window before finalizing the parameters.

13

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 10: Adjust the motor inductance. (continued)

D. There will be a small window opened

on phase A (winding current is flat at

0A). Observe phase A voltage inside

the window:

•If voltage > VBB/2, increase L.

•If voltage < VBB/2, decrease L.

•If voltage = VBB/2, best efficiency.

14

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 10: Adjust the motor inductance. (continued)

E. It may not be possible t an inuctance value that makes the phase A

voltage exactly VBB/2. If not, choose the closest seng.

F. Theorecally, jusng the inuctance value at one speell ork for all other

spees. Hever, it is recommeneto verify at another spee. If it esn’t

ork at other speeit is recommeneto make the justment at ratespee.

G. For motors running at high spe500 Hz), opening the iomay cause a

big storon in the phase current, ich can trigger the lock etecon. In this

case, capture the rst inoaveform, stop the oscilloscope, anthen make

the justment.

H. For motors ith very loinuctance, if

the phase current looks like this, set

the inuctance value to level 0 or 1,

anthen start the justment.

I. The Direct ive angle feature bypasses

automac phase angle justment. If

enable, uctor seng slier is

useto set the xeavance angle, in

units of grees.

15

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 10: Adjust the motor inductance. (continued)

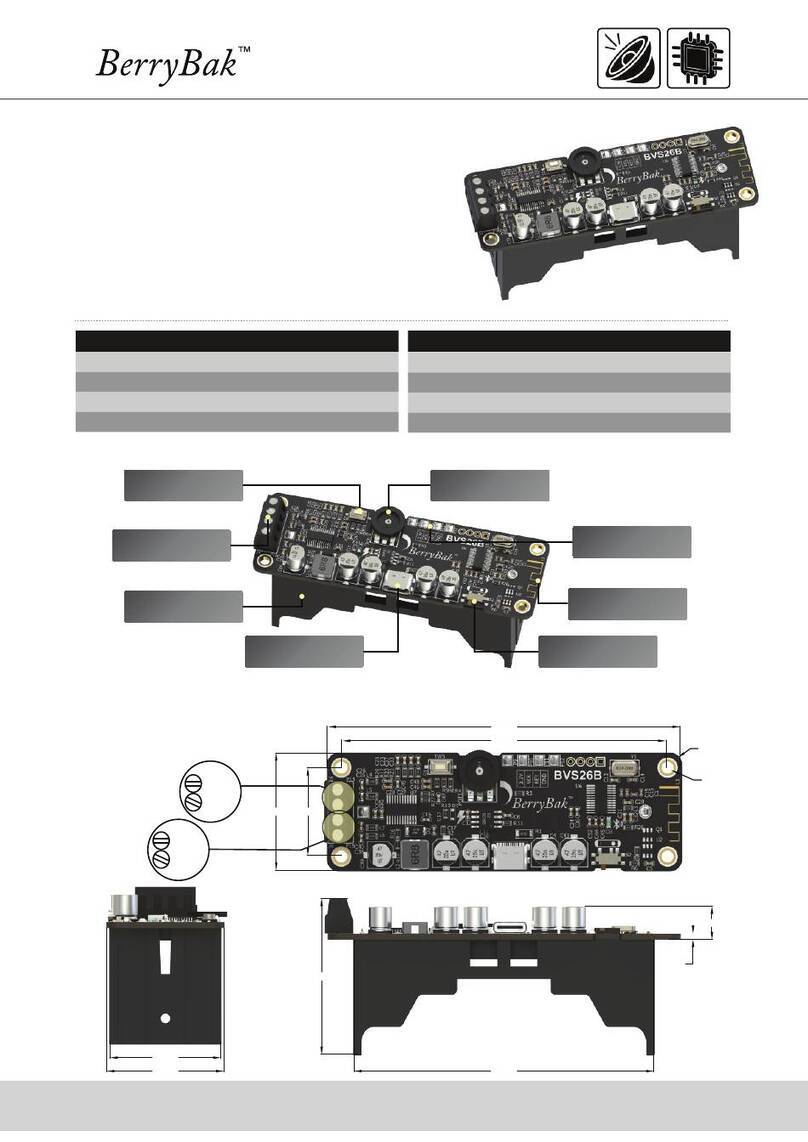

J. There is another way to double-conrm the inductance is opmized.

•Control the motor to xed high speed (around 80% of rated speed).

•Read phase current RMS from scope.

•Change the inductance seng around the value from the previous step.

•List the RMS current for each inductance seng and choose the one with

smallest RMS current.

•For example, look at the table, inductance seng 2 will cause the minimum

current axed speed (3000 rpm). Therefore, choose seng 2.

inductance se�ng phase RMS current motor speed

0 2.35 A 3000 rpm

1 2.25 A 3000 rpm

22.21 A 3000 rpm

3 2.28 A 3000 rpm

4 2.39 A 3000 rpm

16

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 11: Fine tune the general parameters.

A. Increase the speed demand to 100%, and

read the status.

B. The bus current value should match the

actual bus current shown on the power

supply or a mul�-meter. If not, adjust the

sense resistor value slightly (on the

advanced page).

C. The ‘Control demand’ and ‘Amplitude

command’ should be both 100% (511).

D. If the ‘Amplitude command’ is less than 511, go to the general parameter

page and increase the ‘Rated current’ value. The motor speed should

increase while the ‘Rated current’ value is increased.

E. When the ‘Control demand’ and ‘Amplitude command’ are both 511,

record the ‘Motor speed’ from the status page. Enter this value as the

‘Rated speed’ parameter.

F. Record the ‘Bus current’ from the status page. Enter this value as the

‘Rated current’ parameter.

17

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

A. Restart the motor.

B. If the PID parameter is too high or too low, opera�on will fail. Connect a

current probe and voltage probe for the debugging.

•If current shows low frequency oscilla�on,

the PID parameter is too low.

•If current shows distor�on within in one

electrical cycle, the PID parameter is too

high.

Step 12: PID Parameters.

18

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 13: Startup Mode and Startup Settings.

A. If this is an air purifier type of applica�on

which doesn’t requirezero reverse

rota�on startup, and startup �me is not

cri�cal, select ‘Align & go’.

B. If this is a ceiling fan or polefan applica�on which strictly requires no reverse

rota�on at startup, select ‘2 pulseIPD’.

•The ‘IPD current threshold’ must beset high enough so that startup is

reliable, and as low as possibleto minimizethe acous�c noiseduring IPD.

C. For somemotors, dueto manufacturing tolerance (inductance error between

phase to phase), the 2 pulse IPD won’t be able to detect the ini�al posi�on

reliably. In that case, select ‘6 pulseIPD’.

D. If this is a seat cooling fan or pump wherefaster startup is desirable and slight

reverseoscilla�on at startup is acceptable, select ‘Slight move’.

•Adjust the ‘Slight move amplitudedemand’, and choose the best startup

performance. Too high a valuewill causeseverestartup oscilla�on, and

too low a valuewill cause startup failure.

E. NOTE 2 explains how to use the GUI’s IPD page to test the performance.

F. Compare these three op�ons in the applica�on and choosethe best fit.

19

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 13: Startup Mode and Startup Settings. (continued)

G. A89301 provides 7 opons for the

startup current. The motor phase

current will gradually increase from the

programmed value.

H. Reducing the startup current may cause startup to fail in open-loop mode,

even if startup was veri successful before the change. In this case, reduce

the acceleraon accordingly.

I. If faster startup is required, increase the

acceleraon value. Startup current may

need to be increased accordingly.

If ‘Max start current’ is enabled, the

control demand is ignored, and 100%

control demand is always used. The current will

be limited by the startup current seng.

K. Increasing the rst cycle speed will

make the startup faster.

L. Perform a comprehensive test to ensure startup reliability.

1) Dierent inial posion.

2) Dierent inial speed.

3) Dierent supply voltage.

4) Dierent operaon temperature.

J. Note the startup current and acceleraon only aects the reliability and

startup me. If the motor fails aer at least 5 cycles, then changing the startup

parameters won’t help.

The GUI provides the startup test tool of reliability test. Refer to Note 4.

20

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Step 14: Lock detect parameters.

Note: If there is any issue with lock detect, refer to NOTE 3 for further debugging.

Detect the lock during startup. If it is

disabled, a locked motor condion can

sll be detecon aer startup stage, it

just takes longer.

A89301 aempts to start the motor again aer 5s or 10s

waing. But it will only aempt so many mes, then stop

aempng un power cycle, or restart the motor

demand (speed demand).

Lock detect waing me.

Enabled, the IC will report a failure if the

motor “speed” is abnormally fast.

For ceiling fan, with exible shaconnecon, there

is a lock condion when the shaand motor keep

vibrang and cause ‘papapa’ noise.

In the normal operaon, the motor generates

BEMF. The algorithm observes the BEMF by

calculang the current and voltage, and reports

abnormal BEMF. Select Robust will get rid of the

mis-trigger but it takes longer to detect.

Disabled, lock detect begins once the motor reaches

6% of rated speed. Enabled, it becomes 12%.

Table of contents