ALLIANCE ELEVATOR JOURNEY LULA User manual

JOURNEY LULA Owner’s Manual

(Limited Use/Limited Application)

Sales | Service | Installation

80 Hill Avenue | Brantford, Ontario | N3R4H3 | 1.877.707 5004.

IMPORTANT

The Journey Commercial LULA Elevator must be installed, maintained and serviced by an

authorized CAMBRIDGE ELEVATING INC. dealer only. Under no circumstances is anyone

other than a trained and authorized Cambridge Elevating Inc. dealer to install, adjust,

service or modify any mechanical or electrical device on this elevator. As the owner, you

must be aware of your local elevator codes and ensuring periodic elevator maintenace.

Failure to follow this warning can result in safety systems being

compromised or defeated, which can result in serious injury or death.

Cambridge Elevating Inc. Inc. accepts no liability for property damage, warranty claims or

personal injury, including death, in this circumstance. Lift and elevator passenger safety is

the result of countless details in the equipment’s design, manufacture and installation. After

installation, reliable operation and continued assurance of safe operation requires regular

service and inspection to be carried out at an intervals determined by your local elevator

safetey code. Frequent usage and elevator environment may dictate increased service

and inspections. The owner is responsible to ensure that regular service and inspections

occur in a timely manner.

The owner must refer to this manual for operating instructions and precautions for usage of

this Commercial LULA Elevator.

On completion of installation, the dealer must provide the owner with the information

below and ensure it is recorded in the owner’s manual. Any service and/or maintenance

must also be recorded in the Maintenance Record section of this manual by the authorized

Cambridge Elevating Inc. dealer or the owner.

WARRANTY

Your Cambridge Elevating Inc. Dealer will provide a copy of the manufacturer’s limited

parts warranty and documentation relating to any labour warranty offered by your Dealer.

THIS PRODUCT IS DESIGNED AND MANUFACTURED TO EXACT SPECIFICATIONS. MODIFICATIONS

OF THIS PRODUCT IN ANY WAY CAN BE DANGEROUS AND WILL VOID THE WARRANTY.

TABLE OF CONTENTS

GENERAL SPECIFICATIONS Page 1

STANDARD FEATURES Page 1 - 4

OPERATING THE ELEVATOR FROM THE LANDING CONTROLS Page 5

OPERATING THE ELEVATOR FROM THE CAB CONTROLS Page 6

DOOR OPEN BUTTON Page 6

EMERGENCY BATTERY LOWERING Page 6

EMERGENCY LIGHT Page 7

EMERGENCY HANDS - FREE TELEPHONE (OPTIONAL) Page 7

MANUAL LOWERING DEVICE (MACHINE ROOM) Page 8

MAINTENANCE AND INSPECTION CHECKS Page 8

GENERAL SPECIFICATIONS

Load Capacity 1,400 lbs. (635 kg)

Rated Speed 30 feet per minute (0.15 m/s) (Nominal)

Power Supply 220 volt, 1PH, 30 amps | 208 volt, 3PH, 20 amps

Drive System 1:2 Cable Hydraulic

Cab Sizes: 42” Wide x 60” Deep | 48” Wide x 54” Deep | 51” Wide x 51” Deep | Custom

2 stops - 5 stops

Pit Depth Required 14” Minimum 96” Maximum

Overhead Clearance: 11’-6”

Control System Single Automatic Push Button

Floor Selection Magnetic Selector

Sub-Floor Material Plywood

Control Panel Finish Stainless Steel or Brass

Hall Station Finish Stainless Steel or Brass

Motor 5 HP (3.73 kW)

Cab Panel Finish Steel Cab with Plastic Laminate Finish

Lighting Supply 110 volt, 60 Hz, 15 amps

Door Opening 36” x 84” (915mm x 2150 mm) nominal

STANDARD FEATURES

Anti-Creep Re-leveling Device

Automatic Emergency Lighting

Automatic Timed Car Lighting

Digital Floor Indicator in Cab and Hall Stations

Emergency Lowering Valve at Pump

In Car Directional Indicators

Slack/broken Cable Safety Device

Stainless Steel Handrail

Tactile Plates

Upper, Lower and Final Limit Switches

1

STANDARD FEATURES

1) Phase 2 Fire Service Keyswitch (Optional)

The keyswitch in the ON position enables cab controls as per Code A17.1-2007 Section 2.27.

The keyswitch in the OFF position allows for normal lift operation. The keyswitch in the HOLD

position holds the doors open when the cab is at a landing.

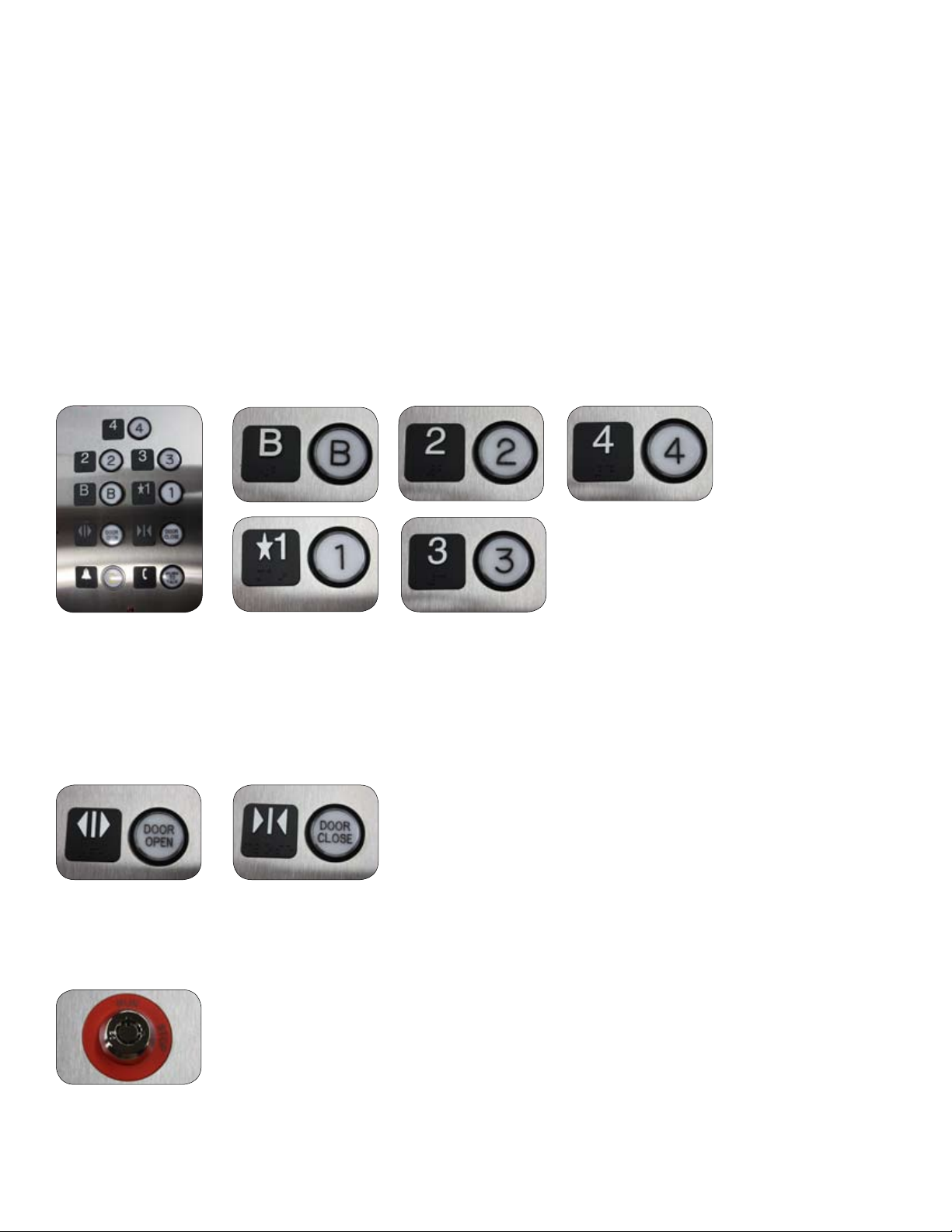

2) Cab Operating Panel (COP) Buttons

Once the selected landing button is pressed, the cab will automatically move to the

landing. The cab will stop when the selected landing is reached.

3) Door Open/Close Buttons

The elevator door will close automatically after a pre-set adjustable time

in seconds. This button can be pressed to open/close the door when the

cab is at a landing.

4) Emergency Stop Keyswitch

The keyswitch can be set to Stop at any time to stop the cab and activate the alarm buzzer.

2

STANDARD FEATURES

5) Alarm Button

The button can be pressed at any time to sound the alarm in case of an emergency.

6) Emergency Light | Digital Position Indicator

The COP emergency light remains ON to provide cab lighting in the event of a main power

failure. The emergency light uses an uninterupted power supply system with an automatic

recharger.

7) Landing Hall Call Station Controls

Hall Call Stations are installed at all landings to move the cab to the landing from which it is

being called. The position indicator displays the oor the cab is at. An optional keyswitch

limits the elevator’s use to authorized persons only. An optional Hoistway Access Hall Station

Keyswitch enables service hoistway access, used with the COP Hoistway Access Keyswitch.

8) Landing Door and/or Gate Interlock

The Landing Door/Gate lock prevents the movement of the cab unless the door/gate is in

the closed and locked position. If the door/gate is not completely closed, the cab will not

move.

3

STANDARD FEATURES

9) Emergency Battery Operation

In the event of a building power failure, the door/gate system is provided with an temporary

power back up system to continue the opening operation for a number of times. On resuming

normal building power, the back up system will turn OFF and begin automatic recharging.

10) Car Top Inspection Station (CTIS)

The CTIS is installed on all lifts and must be operated by qualied inspectors or Cambridge

Elevating Inc. dealer only. Set to NORMAL for normal lift operation, set to INSPECT with all

doors closed and locked for inspection purposes. Press and hold the ENABLE/SAFETY button,

then press and hold UP or DOWN button to run the cab in the selected direction. Set to the

red Stop Button RUN to allow the cab to run UP/DOWN during inspection, set to STOP to stop

the cab from running at any time.

11) Car Top Prop (When required by site conditions)

The Car Top Prop must be operated by qualied inspectors or Cambridge Elevating Inc.

dealers only. It is supplied when insufcient overhead hoistway clearance exists. Raise and

rotate the Prop counter-clockwise to the service position before operating the CTIS. Ensure

the Prop is stowed to normal position before the lift is returned to normal operation.

TO PREVENT SHEAR HAZARDS WHEN OPERATING THE CTIS, ALWAYS KEEP ALL BODY PARTS

INSIDE THE CAB ROOF EDGES AND AWAY FROM ANY HOISTWAY EXTRUSIONS. THE PIT PROP

MUST BE SET TO THE SERVICE POSITION (WHEN EQUIPPED).

4

OPERATING THE ELEVATOR FROM THE LANDING CONTROLS

To call Elevator to the Appropriate Level:

1) Press the CALL ELEVATOR button. The cab will automatically stop at your landing.

2) When the cab reaches the landing, the door lock on the landing door will automatically

release, then if the elevator is equipped with our Automatic 2-Speed Horizontal Sliding Doors

follow this procedure:

a) When the elevator reaches the landing, the sliding doors will open automatically. Enter

the cab and, after a few seconds, the doors will close behind you. Once inside the cab, lock

wheelchair wheels.

NOTE:

When using the landing controls, the cab can only be moved (called) to the level from which

you are calling. When using the control buttons in the cab, the cab can be moved to any

level.

WHEELCHAIR WHEELS MUST BE LOCKED AT ALL

TIMES WHEN THE ELEVATOR IS MOVING.

5

OPERATING THE ELEVATOR FROM THE CAB CONTROLS

1) If sitting in a wheelchair, set the brake on the wheelchair wheels or, if standing, hold on to

the handrail.

2) Press the appropriate oor button to “send” the cab to the desired landing.

3) When the cab reaches the landing, the door lock on the landing door will automatically

release, then: If the elevator is equipped with our Automatic 2-Speed Horizontal

Sliding Doors follow this procedure:

a) When the elevator reaches the landing, the door will “chime” and the sliding doors will

open automatically. Exit the cab and after a few seconds the doors will close behind you.

b) If cab is equipped with a gate, slide the gate open at this time and then open the manual

swing landing door. Exit the cab. Close the gate and then the landing door.

DOOR OPEN BUTTON

Located on the cab control panel of elevators equipped with 2-Speed Horizontal Sliding

Doors. The door open button has the following function:

When the elevator is at a landing level, the 2-Speed Horizontal Sliding Doors can be opened

by pressing the Door Open Button. Normally the doors will have opened and already closed

automatically when arriving at the landing. The Door Open Button allows the door to be

reopened.

EMERGENCY BATTERY LOWERING

This feature allows the lowering of the cab from inside the cab itself, without having to

get someone to manually lower it from inside the machine room. This device operates on

batteries and is only activated in the case of a main building power failure. The operation is

as follows:

1) Press any button below the oor where the elevator is located. The elevator will descend

and stop at the landing.

2) Upon arrival at the desired oor, the automatic doors (if equipped) will open. Exit the cab.

6

EMERGENCY LIGHT

In the event of a main power failure, the emergency cab light will light automatically.

EMERGENCY HANDS - FREE TELEPHONE

1) If your lift is equipped with an Emergency Hands-Free Telephone, press and hold down the

button in the telephone box to activate the phone line. A short time delay (adjustable by the

installing technician) will occur.

2) Release the button once the call is picked up by the telephone line. The system will

automatically dial out to a pre-programmed telephone number as set up by the installing

technician

MANUAL LOWERING DEVICE (MACHINE ROOM) (Figure 4)

TO BE DONE BY TRAINED PERSONAL ONLY!

In the event of power failure, the cab can be moved to a lower level manually by using the

following procedures:

1) Obtain the key to unlock the door to the machine room where the elevator pump unit is

located.

2) Instruct the person(s) in the elevator to remain calm and stay well back from the door of

the elevator. Ease their concern by telling them your intentions.

3) Switch the main disconnect switch to the “OFF” position for the main power supply to the

elevator pump unit.

4) Locate the red Manual Lowering Knob on the pump unit. Twist the Manual Lowering Knob

to lower the cab. See Figure 4. Maintain constant pressure on the knob until the elevator

reaches the lowest landing and stops automatically. (Although you may not be able to see

the elevator, this is readily

detected since there will be no further noise as the oil ows to the reservoir.)

7

MANUAL LOWERING DEVICE (MACHINE ROOM)

5) Obtain the special door release key and open the lower landing door. Assist the

passenger(s) from the cab.

6) After the passenger(s) have exited the cab, make sure hoistway door is closed, reconnect

disconnect switch inside the machine room and lock door behind you.

7) Return the key and special door release key to its original storage area.

UNDER NO CIRCUMSTANCES SHOULD THE PUMP

CONTROLS OR VALVE SETTINGS BE ADJUSTED

EXCEPT BY AN AUTHORIZED CAMBRIDGE ELEVATING INC.

DEALER.

8

MAINTENANCE AND INSPECTION CHECKS

Regular maintenance will keep your elevator in proper operating condition. Please

remember local elevator codes, as the owner of this elevator, you are responsible for making

sure that maintenance and upkeep are done on a regularly scheduled basis by licensed

technicians.

To ensure proper operating condition of your unit, the items listed below must be inspected

and, if necessary, serviced periodically as per local requirements. Additional inspections may

be required depending on usage.

1) Tighten all rail and cab fastening bolts.

2) Lubricate the door mechanism and adjust the door closure if required.

3) Inspect the travelling cable for wear. Replace if any cuts or damage to the jacket is

evident.

4) Check for any hose/pipe leaks. Replace and/or tighten the ttings to correct any

hydraulic leaks found.

5) Check the uid level of the pump reservoir (with the elevator at its lowest landing), and

ll as required. (Use Grade 32 Hydraulic Oil). There must be at least 1” (25 mm) of oil on the

dipstick.

6) Tighten any hose connections or bleeder valves found loose. Check the hydraulic cylinder

(jack) for any leaks. If necessary, the packing seals may have to be replaced.

7) Replace the batteries inside the control panel as indicated on the battery label.

8) Activate and test the safety mechanism.

9

Table of contents