2

HYDROFIT™Owner’s Information Manual

WARNING: The use and ownership of this work is defined in the legend upon the front page hereof.

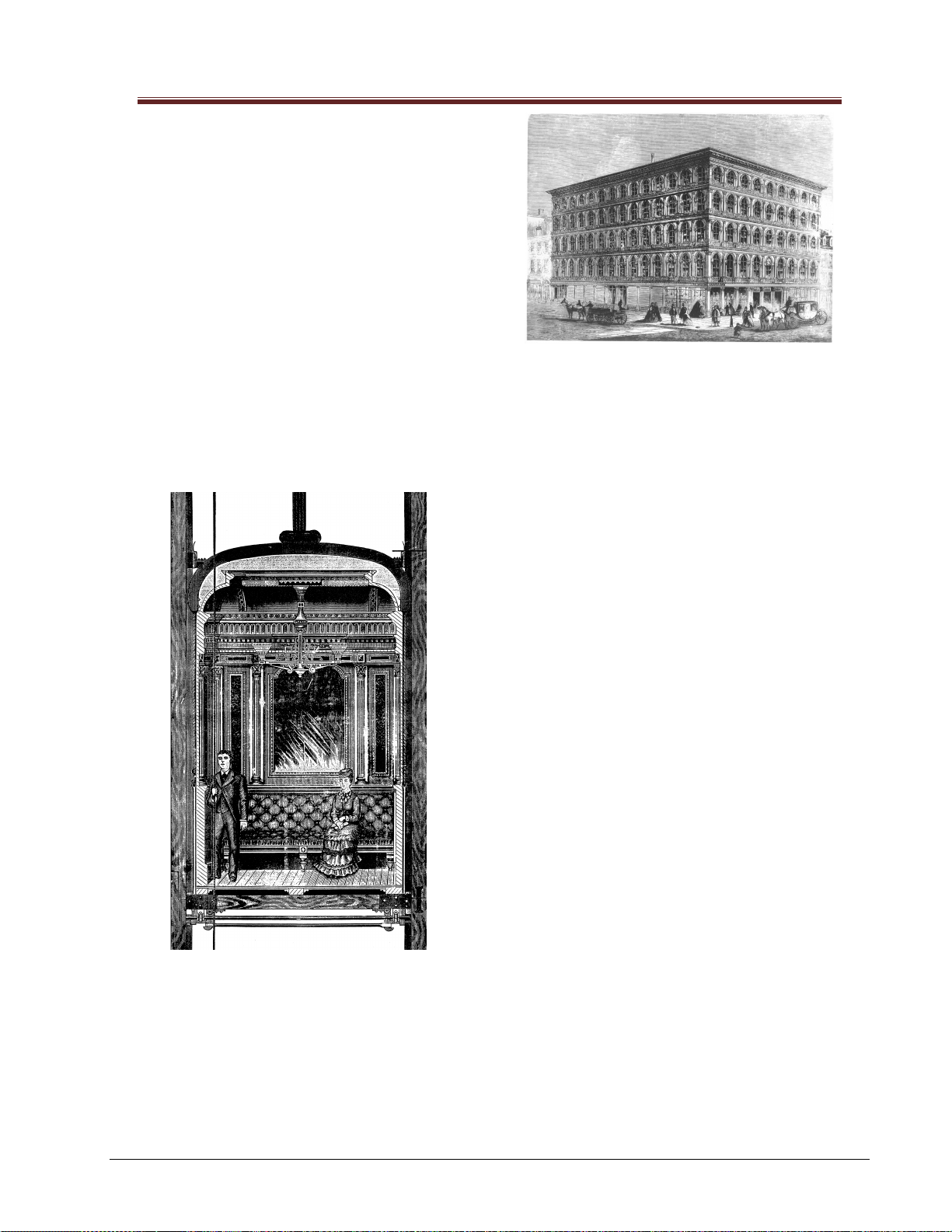

The next problem to overcome was

development of a power source to run

passenger elevators. Factories and

warehouses with freight elevators were

near water, but passenger elevators would

be installed in stores, office buildings, and

hotels, away from any central power source

(this was 22 years before the opening of

the first U.S. electric power station).

Otis’ solution was to invent a small,

oscillating steam engine to power each

elevator. So in 1857, he designed, built,

and installed the first Otis safety passenger

elevator, in the E.V. Haughwout Store in

New York City.

1857: The first passenger elevator ever

built was installed in the E.V. Haughwout

Store in New York City

1873: The elevator operator manipulates

the control rope, regulating the direction

and speed of the car.

Elisha Otis was a master mechanic and

engineer. He obtained many patents in the

1850s, including the safety device he

invented in 1852, the oscillating steam

engine, a brake, steam plows, and a rotary

oven for bakeries.

Unfortunately, at the age of 50, Otis died

suddenly during a diphtheria epidemic in

1861. His sons, Charles and Norton, took

over the business and utilized the elevator

expertise their father taught them. They

renamed the company N.P. Otis & Brother,

then in the late 1860s changed it to Otis

Brothers & Company.

Otis Brothers & Co. patented some 53 new

advancements in elevator equipment,

including hoisting apparatus, brakes, steam

hoist, and pulleys. The brothers continued

to use world’s fairs and industrial fairs to

showcase their elevator technology and

create an international market for Otis

elevators.