Alliance Steel AllianceLok 16 User manual

© Alliance Steel, Inc. 2015

THE NEW AND IMPROVED ALLIANCELOK 16

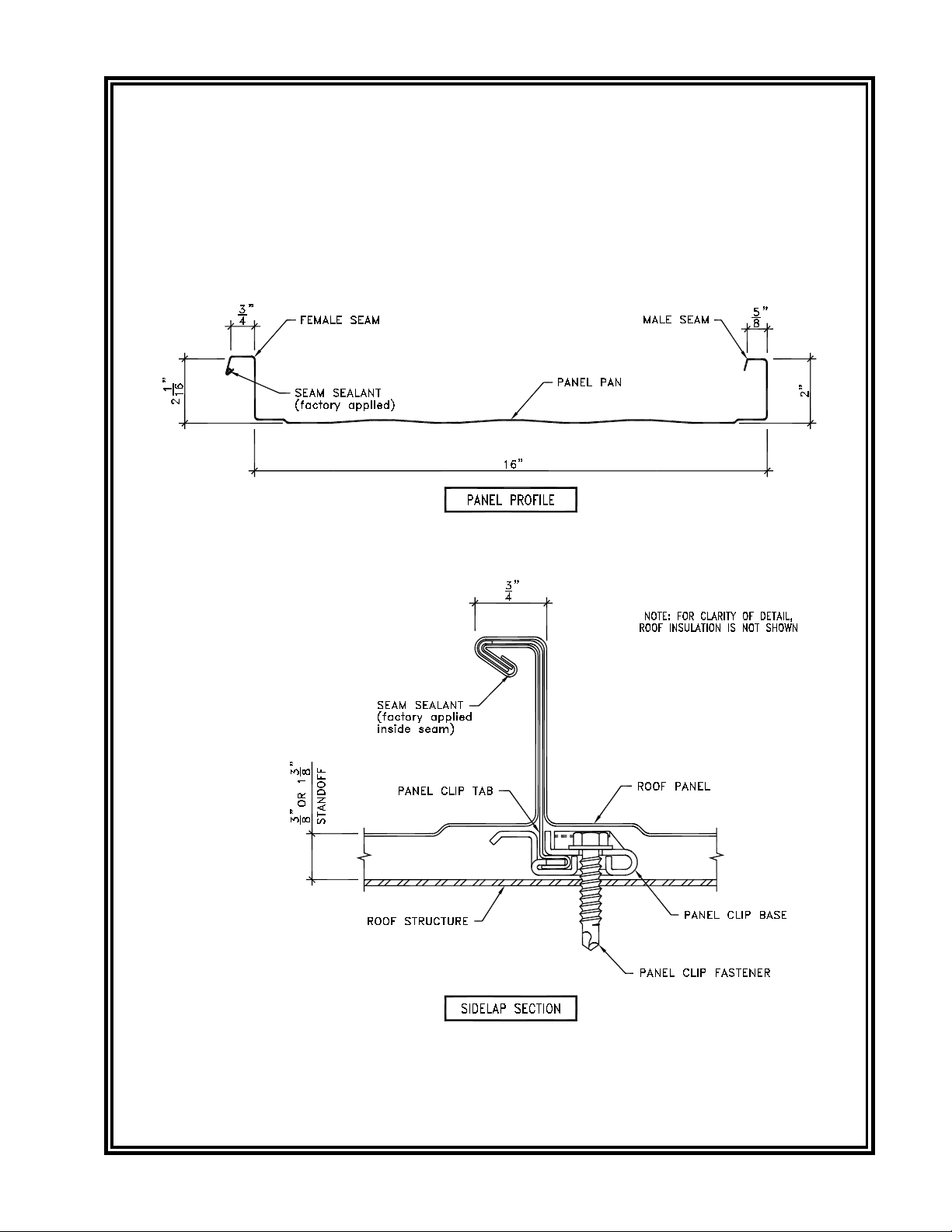

UNIVERSAL STANDING SEAM ROOF SYSTEM

INSTALLATION GUIDE

TripleLok™ Seam

Page 1

Dwg:

Date:

The New & Improved AllianceLok 16 Roof Systems Installation Guide

June 2015

INDEX

1.0 GENERAL

1.1 Purpose of the Installation Guide...................................................................................................... 2

1.2 Customer’s Responsibility ................................................................................................................ 2

2.0 SAFE ROOF INSTALLATION

2.1 Erector’s Responsibility .................................................................................................................... 3

2.2 OSHA................................................................................................................................................ 3

2.3 Walking & Working on Roof Panels .................................................................................................. 3

2.4 Handling Roof Materials in Strong Winds ......................................................................................... 4

3.0 CHECKING THE STRUCTURE

3.1 Completed and Braced ..................................................................................................................... 5

3.2 Lateral Stability ................................................................................................................................. 5

3.3 Alignment .......................................................................................................................................... 5

4.0 RECEIVING & HANDLING ROOF MATERIALS

4.1 Equipment for Unloading and Lifting................................................................................................. 6

4.2 Material Inventory ............................................................................................................................. 6

4.3 Lifting Roof Panel Bundles ............................................................................................................... 6

4.4 Field Storage of Roof Materials ........................................................................................................ 7

4.5 Handling Individual Roof Panels....................................................................................................... 8

5.0 ROOF INSTALLATION BASICS

5.1 Proper Tools..................................................................................................................................... 9

5.2 Equipment List .................................................................................................................................. 9

5.3 Sealants............................................................................................................................................ 9

5.4 Fasteners.......................................................................................................................................... 10

5.5 Field Cutting Panels and Flashing .................................................................................................... 11

6.0 ROOF PANEL LAYOUT

6.1 Sheeting Direction and Modularity.................................................................................................... 12

6.2 Layout & Checking for Coverage...................................................................................................... 12

6.3 Appearance Considerations.............................................................................................................. 12

7.0 INSPECTION OF ROOF ASSEMBLY DURING INSTALLATION

7.1 Importance of Inspection .................................................................................................................. 13

7.2 Inspection List................................................................................................................................... 13

8.0 STANDARD PARTS

8.1 General ............................................................................................................................................. 16

8.2 Standard Parts Details...................................................................................................................... 17

9.0 ROOF INSTALLATION DETAILS

9.1 General ............................................................................................................................................. 22

9.2 Preparation for Roof Panel Installation ............................................................................................. 23

9.3 Roof Panel Installation...................................................................................................................... 29

9.4 Termination Panel Installation........................................................................................................... 54

9.5 End Dam Installation......................................................................................................................... 62

9.6 Gable Trim Installation ...................................................................................................................... 70

9.7 Rake Transition Trim Installation....................................................................................................... 76

9.8 Ridge Cap Installation....................................................................................................................... 79

9.9 High Eave Transition Trim Installation .............................................................................................. 86

9.10 Eave Gutter Installation .................................................................................................................. 90

9.11 Hip and Valley Installation............................................................................................................... 94

The New & Improved AllianceLok 16 Roof Systems Seaming Guide............................................................ 97

The New & Improved AllianceLok 16 Roof Systems Architectural Details ................................................... 117

The New & Improved AllianceLok 16 Roof Systems Maintenance & Warranty Info .................................... 141

INDEX

Page 2

Dwg:

Date:

The New & Improved AllianceLok 16 Roof Systems Installation Guide

June 2015

1.0 GENERAL

1.1 Purpose of the Installation Guide

This Installation Guide is provided to Alliance Steel,

Inc. (“Alliance”) customers and their erectors as the

recommended procedure for the correct assembly of the

AllianceLok 16 Roof System.

This guide is intended to be used in conjunction with the

project’s Erection Drawings to help plan and organize

the installation of the AllianceLok 16 Roof System. The

Erection Drawings identify the applicable roof conditions

and govern specic part arrangements. This Installation

Guide will help you identify parts, establish the installation

sequence, demonstrate correct assembly, and point out any

areas or procedures requiring special emphasis or attention.

This Installation Guide applies to the standard AllianceLok

16 Roof System. Custom roof conditions, including custom

details and instructions, will be covered by the Erection

Drawings. In case of conict between this Installation

Guide and the Erection Drawings, the Erection

Drawings will have precedence.

1.2 Customer’s Responsibility

The customer is responsible for proper installation of the

roof in accordance with the Erection Drawings and this

Installation Guide, and in accordance with good engineering

and construction practices.

The customer must take the responsibility for selecting

a competent erector, insist that the work be performed

by qualied and experienced standing seam metal roof

installers, insist that the erector take time to study and

understand this guide, then assure that the erector correctly

follows the guide’s instructions.

Alliance does not guarantee and is not liable for the quality

of erection. Alliance is not responsible for building defects

that may be attributed to improper erection or the negligence

of other parties.

Clarification concerning the AllianceLok 16 roof

installation should be directed to the Alliance Customer

Service Department.

Contact the Alliance ofce:

Alliance Steel, Inc.

3333 S. Council Road

Oklahoma City, OK 73179-4410

(405) 745-7500 or (800) 624-1579

GENERAL

1.3 Weather Tightness Warranty Requirements

(if applicable)

Depending upon the type of warranty, Alliance may

require the roof installer to be certied by the manufacturer.

Warranty requirements should be veried on contract with

Alliance.

Alliance must approve in writing all roof penetrations prior

to installation. This includes but is not limited to; Roof Curbs,

Vent Pipes, & Mechanical Equipment. Submittals should

be forwarded to Alliance for review.

It is the customers responsibility to coordinate warranty

inspections with the Alliance warranty department.

Any special applications with regards to the weather

tightness of this roof system should be brought to the

attention of the warranty department at Alliance.

Page 3

Dwg:

Date:

The New & Improved AllianceLok 16 Roof Systems Installation Guide

June 2015

2.0 SAFE ROOF INSTALLATION

2.1 Erector’s Responsibility

The erector of the roof system is responsible for the safe

execution of this Installation Guide. These instructions are

intended to describe the sequence and proper placement

of parts. They are not intended to prescribe comprehensive

safety procedures.

If the erector cannot safely assemble the roof in accordance

with these instructions, it is the responsibility of the erector

to stop the work and contact Alliance to determine alternate

assembly procedures.

2.2 OSHA

The Occupational Safety and Health Act (OSHA) has

promulgated many regulations applicable to the

installation of this or any other roof system. These

regulations, identied as Part 1926, Safety and Health

Regulations for Construction, are available from any

government bookstore. The objective of the OSHA

standards is to protect the worker from injury or illness.

These OSHA regulations should be recognized as job site

requirements and be fully complied with.

Failure to do so may result in substantial nes in the event

of an OSHA inspection. Safe installation practices may

be further dened and made mandatory by state or local

ordinances.

Maintaining good housekeeping on the jobsite is

recognized as being important to both OSHA compliance

and to successful job completion.

2.3 Walking & Working on Roof Panels

Do not walk on the last installed panel run, as the

unsecured edge could collapse under a person’s weight.

When installing clips or making endlap connections, etc.,

stand where the Roof Structural will support your weight.

An approved and safe walking platform should be used

in high trafc areas to prevent the Roof Panel from being

deformed, scratched, or scuffed.

A. PLACING PANELS ON THE STRUCTURE

Do not place bundles of panels on the Roof Structure

without rst verifying the structure will safely support the

concentrated weight of the panels and the weight of the

installation crew. Some Roof Structures may not be

designed to support the weight of a full panel bundle without

additional structure support.

B. WALKING ON ROOF PANELS

Do not use a Roof Panel as a working platform. An

unsecured panel could collapse under the weight of a

person standing between purlins or at the panel end.

C906.200

SAFE ROOF INSTALLATION

Assembled

Sidelap

(Typ.)

Leading Roof Panel

Unassembled

Sidelap

CAUTION — INCORRECT

DO NOT step on leading (unsecured) Roof Panel.

Assembled

Sidelap (Typ.)

Leading Roof Panel

Unassembled

Sidelap

CORRECT

Step ONLY on secured Roof Panels

Page 4

Dwg:

Date:

The New & Improved AllianceLok 16 Roof Systems Installation Guide

June 2015

2.0 SAFE ROOF INSTALLATION

2.3 Walking & Working on Roof Panels (Continued)

C. SAFETY EQUIPMENT

The use of safety equipment for the Roof Panel installation

is recommended at all times during the installation process.

However, when using lanyards, ensure that the clasp, belt

hooks and wire cables are covered in such a manner that

they will not scratch the panel surface if accidentally dragged

along the panel.

D. CREW SIZE

The length of the individual Roof Panels should be

considered when determining the crew size. It is

recommended that under normal conditions, there be

one person for every ten feet of panel length, plus one.

E. PANEL OVERHANG

Do not stand on the end of unsupported (cantilevered)

panels at the eave or ridge. Standing on the cantilever

portion may result in panel collapse.

F. POINT LOADS

When properly supported by the structurals, panels are

designed to support uniform loads, which are evenly

distributed over the panel surfaces. Point loads that occur

in small or concentrated areas, such as heavy equipment,

ladder or platform feet, etc., may cause panel deformation

or even panel collapse.

G. SLICK SURFACES

Panel surfaces and structural steel surfaces are hard,

smooth, and nonabsorbent, which causes these surfaces

to be very slick when wet or covered with snow or ice.

Even blowing sand or heavy dust can make these surfaces

difcult to walk on without slipping.

Unpainted panel surfaces are often coated with oil to

accommodate the panel-fabrication process. Although

designed to wash away or evaporate during normal weather,

the oil on new panels can be extremely slick, especially

during periods of light rain or dew.

Caution must be exercised to prevent slipping and falling

onto the roof surface or even sliding off the roof. Non-slip

footwear is a necessity and non-slip working platforms are

recommended.

H. ELECTRICAL CONDUCTANCE

Metal panels are excellent electrical conductors. A common

cause of injury is the contact of metal panels with power

lines during handling and installation. The location of all

power lines must be noted and, if possible, agged. The

installation process must be routed to avoid accidental

contact with all power lines and high voltage services and

equipment. All tools and power cords must be properly

insulated and grounded and the use of approved ground

fault circuit breakers is recommended.

I. FALSE SECURITY OF INSULATION

Blanket and board insulation blocks the installer’s view of

the ground below the roof. Serious injury can occur when

the installer gets a false sense of security because he

cannot see the ground and steps through the insulation.

J. SHARP EDGES

Some edges of panels and trim are razor sharp and can

cause severe cuts if proper protective hand gear is not

worn. Be careful not to injure others while moving panels

and trim.

2.4. Handling Roof Materials in Strong Winds

Do not attempt to move panels in strong winds. Wind

pressure can easily cause a man to lose balance and fall.

Strong wind uplift on a panel can lift the weight of the man

carrying the panel.

Loose, wind borne panels are very dangerous and can

cause severe injury and damage.

Secure stacks of panels with banding or tie-downs, so

wind will not blow the panels off the roof. Clamp individual

unsecured panels to the Roof Structurals. Clamp or block

panel bundles and accessory crates to prevent them from

sliding down the roof slope.

SAFE ROOF INSTALLATION

Table of contents

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual