7

Furnace Operation

In the heating mode, gas is burned and the products of

combustion are drawn through a heat exchanger by an

induced draft blower. The flue gases are then exhausted

from your home through a flue pipe system. The furnace

circulator blower passes indoor air over the heat ex-

changer and then through the conditioned space.

Thermostat Functions

This furnace requires a two-stage thermostat. A two

stage thermostat controls which firing rate is used

depending on the temperature difference between the

set point and the room temperature. If the difference is

small, the thermostat will energize the furnace on the low

stage. If the temperature difference is high, the thermo-

stat will energize the furnace on high stage. A two stage

thermostat and furnace properly used will maintain a

much tighter control of temperature than a conventional

single stage thermostat and furnace.

For optimal operation of this furnace, set the thermostat to

the temperature desired. Do not over adjust the thermostat

to turn the heat on. This will cause the high stage heat to

come on when the low stage heat could have satisfied the

demand. Setting the temperature to the desired tempera-

ture will minimize temperature fluctuations.

In addition, there are thermostats that automatically

switch from Heating to Cooling and with night setbacks.

The night set-back, or multiple set-back type, will adjust

the temperature at night or during the day when no one

is at home, saving energy and lowering fuel bills.

General Information

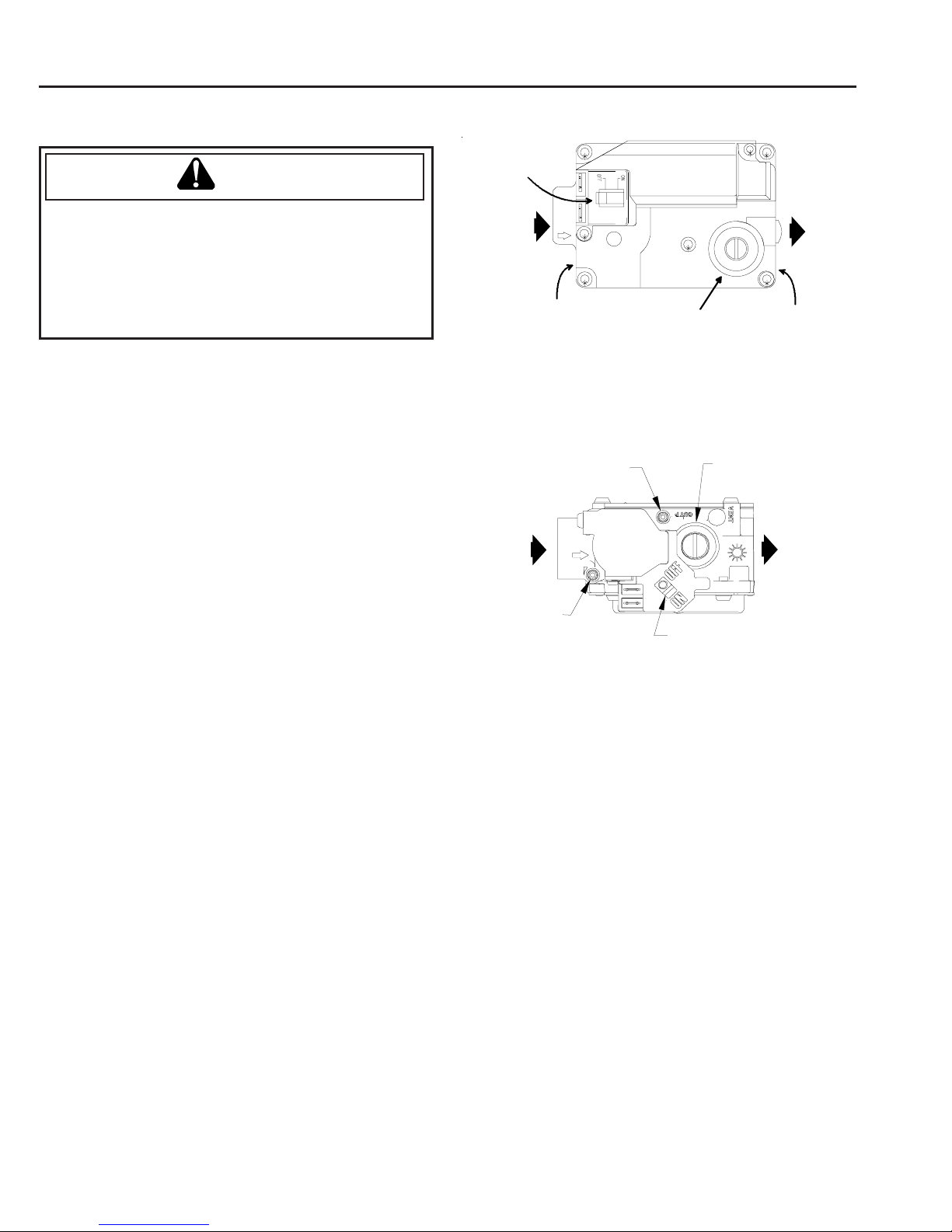

Fan Switch

Cool/Heat

Switch

Cool/Heat

Temperature

Control Dials

Room Temperature

Thermostat

System

Switch

Fan

Switch Action

OFF

UTO None

COOL AUTO System only cools, fan

cycles off and on.

COOL ON System only cools, fan

runs all the time.

HEAT AUTO System only heats, fan

cycles off and on.

HEAT ON System only heats, fan

runs all the time.

OFF ON No heating or cooling,

fan runs all the time.

Typical Thermostat

General Information

WARNING

Electrical components are contained in both

compartments. To avoid electrical shock, injury or

death, do not remove any internal compartment

covers. Contact a qualified servicer at once if an

abnormal condition is noticed.

Notice:

Do not use this furnace if any part has been under water.

Immediately call a qualified servicer to inspect the

furnace and to replace any part of the control system and

any gas control which has been under water.

Keep both doors in place except for inspection and

maintenance. An interlock switch prevents furnace

operation if the blower door is not in place.

Dehumidistat

The dehumidistat (not included in furnace) controls

excessive humidity in the home. To operate, set the

dehumidistat to the desired relative humidity level. If the

cooling system is wired to the furnace controls and is

running, the furnace blower will lower its speed to

improve dehumidification, if needed.

Refer to Specification Sheet for available dehumidistats

(not included in furnace).

Self Diagnostic Electronic Control Module

Certain furnace models are equipped with a self-diag-

nostic electronic control module. If a furnace component

is not operating properly, the control module will repeat-

edly flash a red light on and off in a factory-programmed

sequence, depending on the problem encountered.

If a furnace equipped with a self-diagnostic module is not

operating properly, look through the observation window

in the blower access door and make note of the number

of flashes in the sequence. Contact a qualified servicer

for further information. Do not attempt to troubleshoot the

problem yourself.

Gas Valve

The gas valve regulates gas flow to the burners in

response to input from the integrated control module.

Igniter

The furnace has an electronic ignition device which lights

the burners automatically. Never try to light the burners

by hand.

Blowers

This furnace has an induced draft blower which draws

flue products through the heat exchanger and exhaust

them outdoors. It also has a circulator or main blower

that passes indoor air over the heat exchanger and into

the conditioned space. Both blowers are permanently

lubricated, no further oiling is required.