3

3. If at all possible, it is recommended that the kiln be kept in a separate room to avoid excess heat in the work

areas. This also helps to prevent accidents if children are present.

4. Install it in a well ventilated, sheltered area such as a carport, garage, utility or hobby room. It should be conve-

nient to your clay working area, and out of the way of other traffic.

5. If possible, locate the kiln in a room with a cement floor or other type of non-combustible material.

6. Never fire your kiln within a four sided cabinet or closet. The fourth side must always be open to room air to pre-

vent the kiln from overheating surrounding surfaces. It is best to leave a least two sides open for easy access to

controls and peep holes.

7. Keep curtains, aprons, plastic or other flammable materials away from your kiln.

The outside of an octagon or round kiln will get hotter faster than the outside of a square kiln because of

different insulation methods. Our tests reveal that at the end of 9 hours of firing at cone 9 (2336°F, 1280°C inside

the firing chamber), the surface temperature of an AMACO®square kiln will reach approximately 250°F (121°C)

while the surface temperature of a round kiln will reach 450°F (232°C). Regardless of the type of kiln you are

using, always:

1. Wear dark-shaded glasses (shade number 1.7-3.0) for looking into peephole and use protective

kiln gloves when kiln and/or ware are hot.

2. Allow only a qualified adult to operate or touch a kiln.

Test Firing

Orton Self-Supporting Cones and Pyrometric Bars are provided for your test firings. Use the Self-Supporting Cones on your

kiln shelves and the Bars in your Kiln-Sitter®as described in the Cones for Ceramics booklet. One bag is provided for each

firing. Orton Pyrometric Cones and Bars measure the amount of heatwork seen by the ware in the kiln. They are much

more accurate than any temperature measuring device. Using cones provides an accurate measure of what happened dur-

ing firing and allows differences between firings to be detected.

Prior to installing the AMACO®KilnVent, make a firing with a series of witness cones on each shelf in the kiln. After instal-

lation, make another firing using witness cones and compare the results. We are confident you will be pleased with the

improvement in heat distribution.

Kiln Preparation

Preparing the Kiln for KilnVent Installation

Make sure your kiln is unplugged before beginning installation. If it is a multiple ring design, you may wish to remove the

top ring(s) to make it easier to drill through the floor of the kiln.

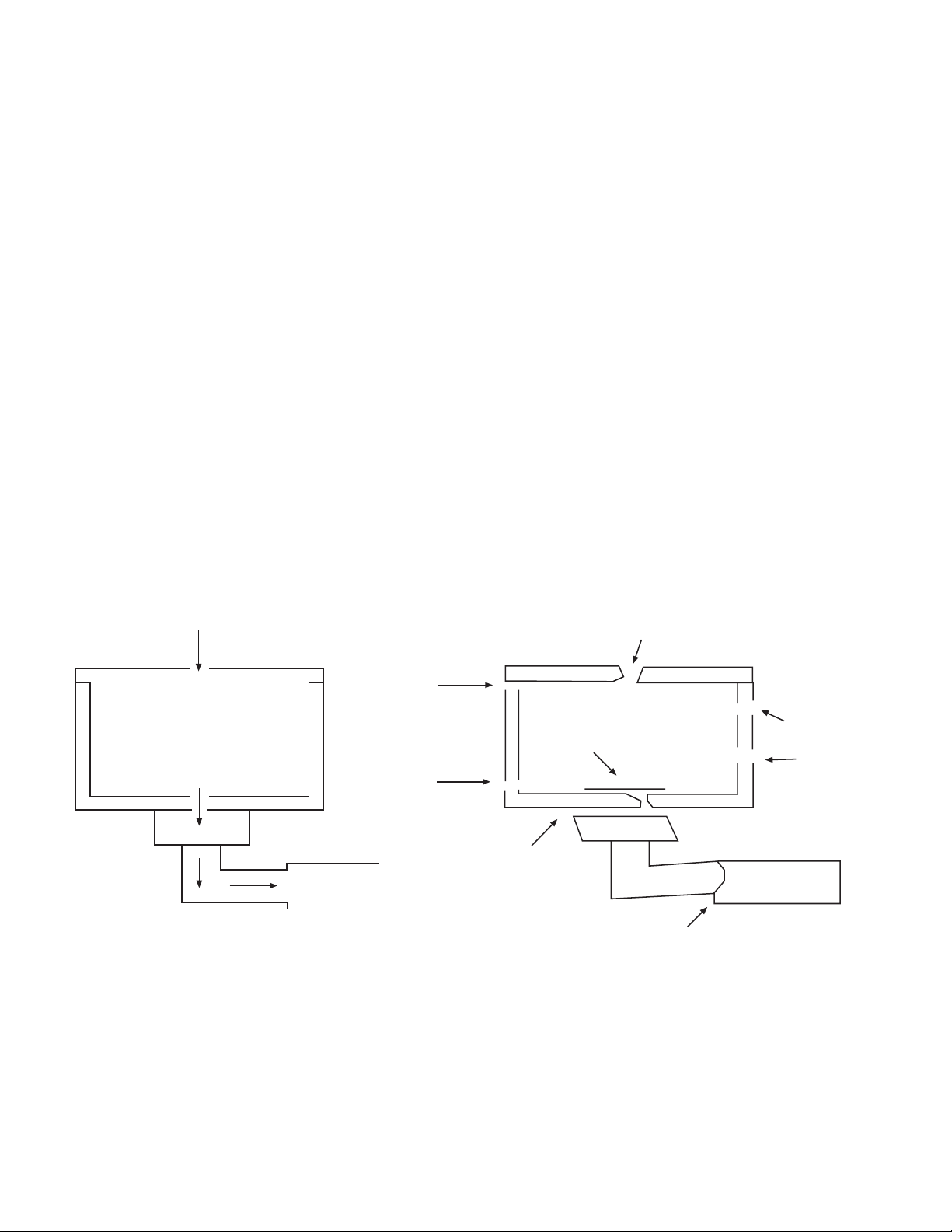

Drilling Ventilation Holes in the Kiln Floor (Suspended and Stand Kiln Vents Only)

Locate and mark the center of your kiln floor. Refer to the chart on page 4 to determine the correct number and size of

holes. Refer to the diagrams on page 4 for correct hole pattern. For larger oval kilns resting on two stands, holes should

be drilled in that portion of the kiln under which the KilnVent will be located.

Drill the correct number of LARGE and SMALL ventilation holes around the center mark. Cluster the holes as close togeth-

er as you desire, but do not space them out too far. They must fit within a 41⁄2" diameter at the center of the floor to align

with the hole in the plenum chamber of the AMACO®KilnVent—Suspended Version or Stand Version which will be located

below it.

If your floor is supported by a metal plate, use an electric drill. For standard firebrick kiln floors or refractory fiber kilns, the

drill bit can be rotated by hand, OR, firmly support the floor of the kiln on a piece of scrap wood and use an electric drill

to slowly drill through the floor into the wood. Precision and care are important. If you just “drill away” with an electric

drill alone, an oversize hole and chipping of the underside may result. Vacuum out any dust that gets in your kiln from

drilling.

It is best to drill holes before installing the AMACO®KilnVent since dust may damage its motor.

AMACO®KILNS DO NOT REQUIRE VENTILATION HOLES IN LID OR FRONT DOOR. PEEPHOLE OPENING IS PROVIDED.