RS2310004 Rev. 1 2

Table of Contents

Important Information .................................................. 4

Introduction

General Information ................................................ 5

Model Identification and Ordering

Replacement Parts.................................................. 5

Amana Cooking Products Nomenclature................ 5

Safety Information

Safety Practices for Servicer .................................. 7

Servicing ................................................................. 7

Receiving Oven ...................................................... 7

Using the Oven ....................................................... 8

Baking, Broiling, and Roasting................................ 8

Connecting Range to Gas....................................... 8

Electrical Requirements .......................................... 9

Extension Cord........................................................ 9

Grounding................................................................ 9

Product Safety Devices ........................................ 10

Installation Instructions Open Burner

Packing Material ................................................... 11

Range Location ..................................................... 11

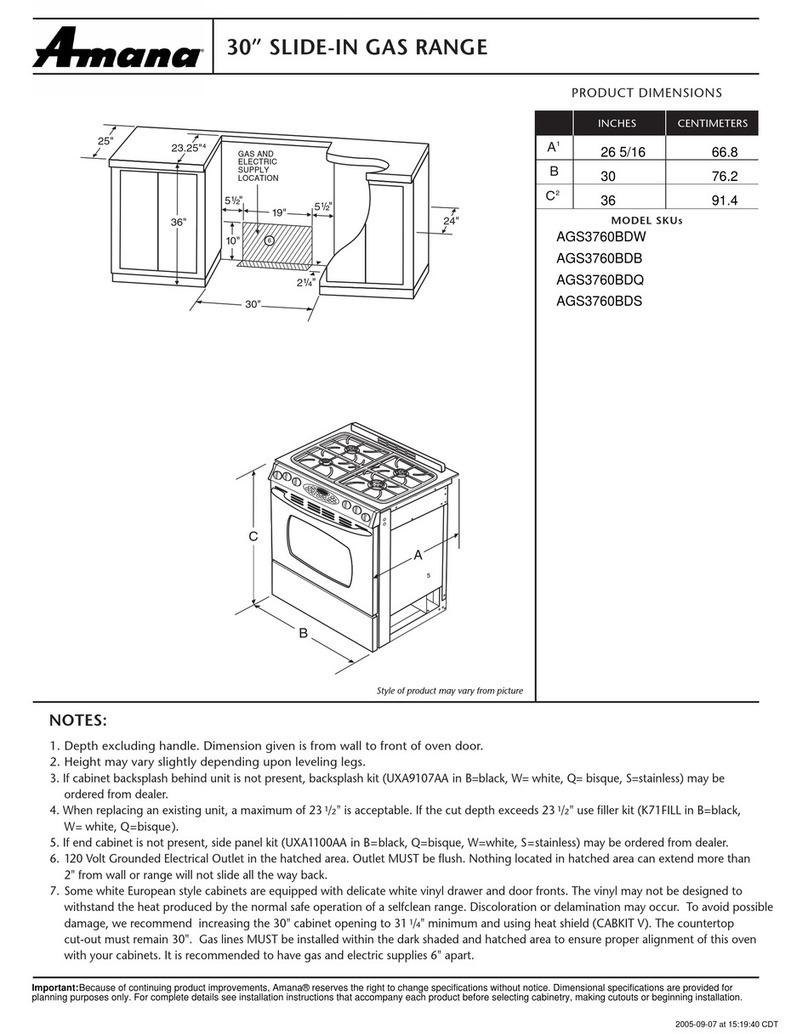

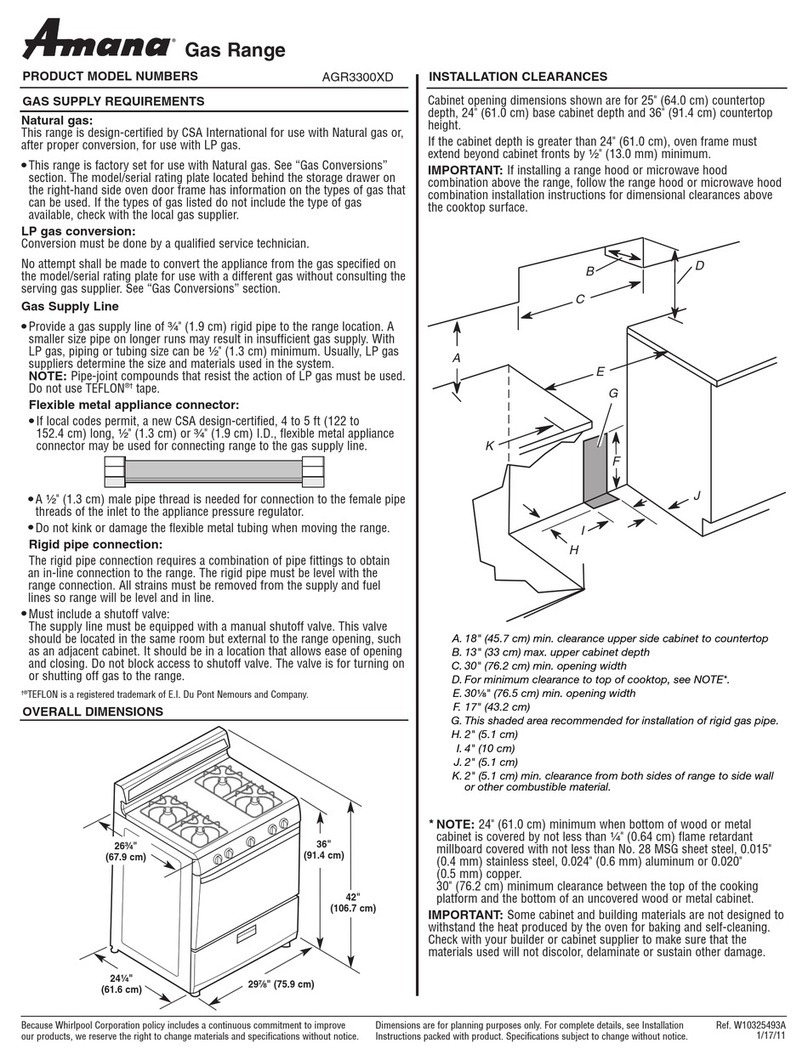

Cabinet Opening ................................................... 11

Minimum Clearances to Combustible Surface ..... 11

Special Countertop Conditions ............................. 12

Gas Connection Requirements ............................. 12

Gas Supply Location ............................................. 12

Gas Supply Pressure ............................................ 12

Pressure Regulator Location................................. 12

Converting for Use with Natural Gas or

Propane Gas ......................................................... 13

Anti-tip Bracket Installation ................................... 15

Gas Connection .................................................... 16

Testing for Gas Leaks ........................................... 16

Seal Openings....................................................... 17

Place Range.......................................................... 17

Removal and Replacement of Range................... 17

Igniting and Adjusting Top Burner Pilot Flame ..... 17

Test and Adjusting Surface Burner Flame............ 17

Remove Shipping Screws..................................... 18

Place Rangetop and Grates.................................. 18

Ignite Oven Burner Pilot ....................................... 18

Test and Adjust Oven Burner Flame .................... 18

Installation Instructions Sealed Burner

Packing Material ................................................... 19

Range Location ..................................................... 19

Cabinet Opening ................................................... 19

Minimum Clearances to Combustible Surface ..... 19

Special Countertop Conditions ............................. 20

Electrical Connection Requirements..................... 20

Electrical Connection Clearance........................... 20

Gas Connection Requirements ............................. 20

Gas Supply Location ............................................. 21

Gas Supply Pressure ............................................ 21

Pressure Regulator Location................................. 21

Converting for Use with Natural Gas or

Propane Gas ......................................................... 22

Anti-tip Bracket Installation ................................... 24

Gas Connection .................................................... 25

Testing for Gas Leaks ........................................... 26

Seal Openings....................................................... 26

Place Range.......................................................... 26

Removal and Replacement of Range................... 26

Place Grates and Burner Caps ............................. 26

Test and Adjusting Surface Burner Flame............ 27

Test and Adjust Oven Burner Flame .................... 27

General Information

Operating Surface Burners ................................... 28

Operating Surface Burner during a Power Failure 28

Cooking Utensils ................................................... 29

Prepare to Bake .................................................... 30

Baking ................................................................... 30

Adjusting Factory Set Baking Temperature.......... 31

Prepare for Broiling ............................................... 31

General Care and Cleaning

Removing Oven Door ........................................... 32

Remove Grid, Pan, and Rack ............................... 32

Removing Oven Bottom ....................................... 32

Open Burner Care and Cleaning

Removing Rangetop and Grates .......................... 33

Removing Surface Burners................................... 33

Cleaning Surface Burners ..................................... 34

Sealed Burner Care and Cleaning

Place Grates and Burner Caps ............................. 36