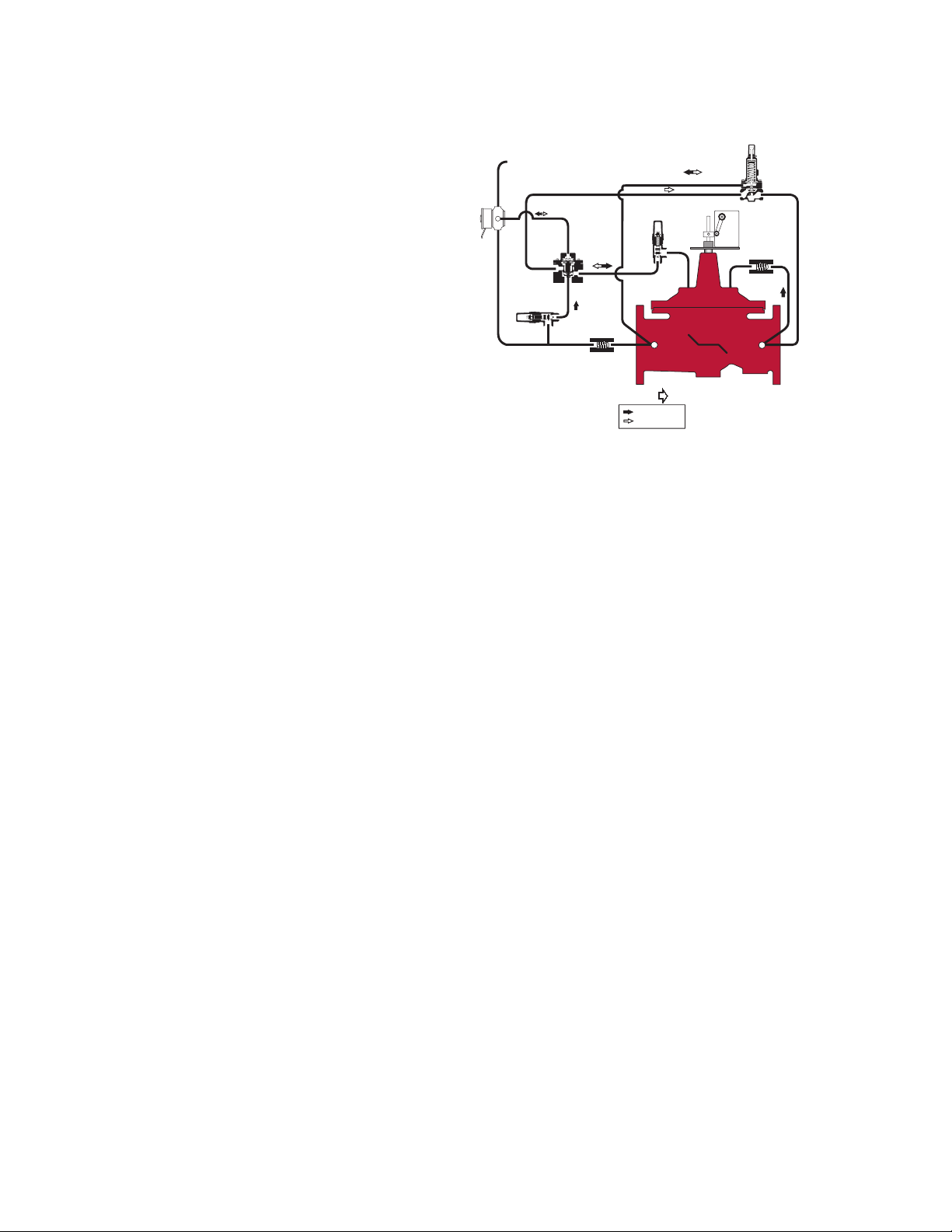

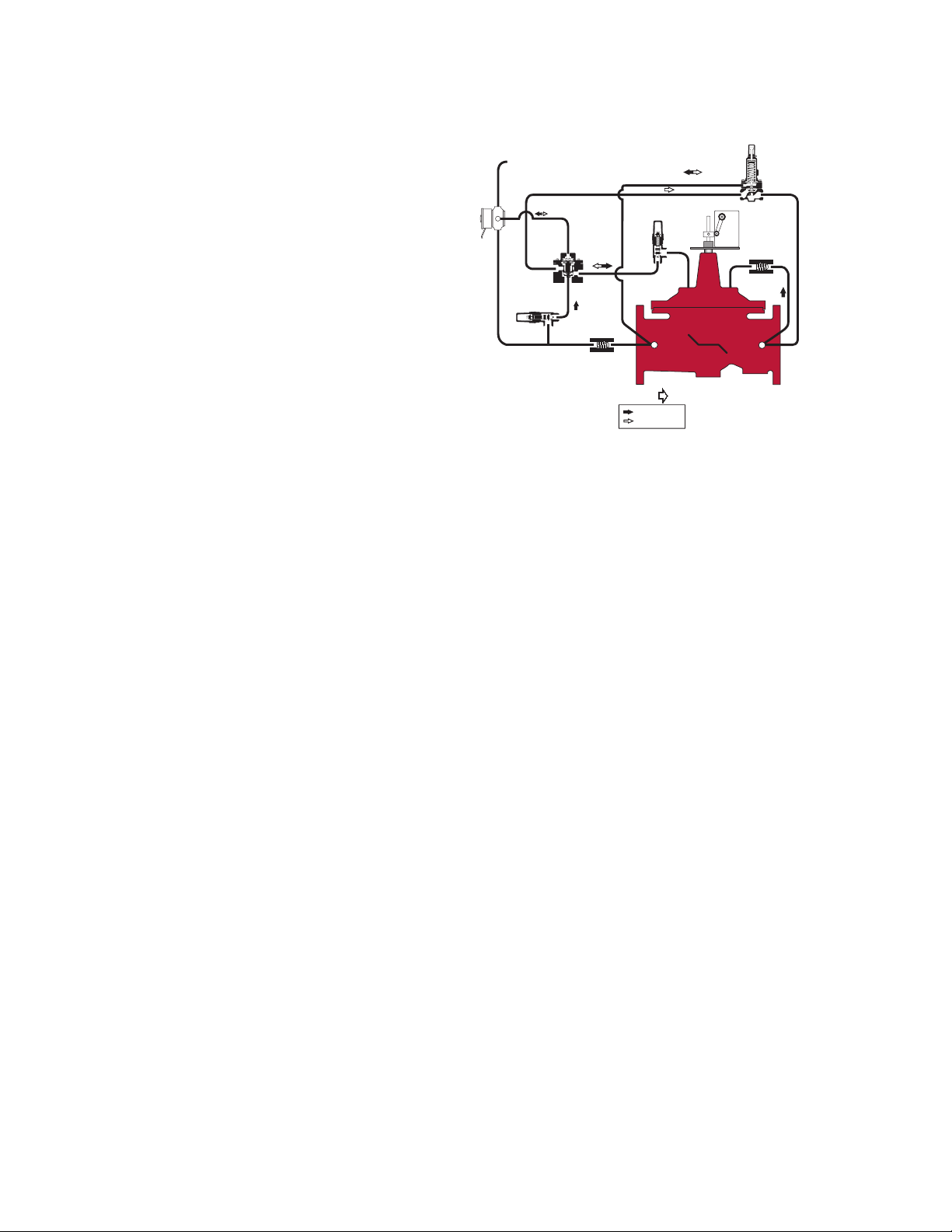

982GD (Globe) Pump Control Control Valve with Backpressure Feature

2 IOM-A-ACV-982_682 2115 EDP# 1917092 © 2021 Watts

Standard Components

Operation

The Pump Control Valve with Backpressure Feature is designed to

minimize the surges associated with the starting and stopping of

pumps. The valve slowly opens and closes as required to control

pumping related surges, and throttles to maintain a minimum back-

pressure against the pump during the pumping cycle. The pump

starts and stops against a closed valve.

Pump Start Up: When the pump is signaled to start, the 3-Way

Solenoid is energized, directing pressure into the cover chamber of

the 3-way Accelerator Pilot. The Accelerator Pilot allows the main

valve cover chamber to be vented downstream, causing the valve

to open at a controlled rate, gradually admitting pumping pressure

into the distribution system. The rate of opening is controlled by the

adjustable opening speed control, which restricts the speed of fluid

and pressure evacuating the main valve cover chamber. The valve

remains open during the pumping cycle.

Backpressure Feature: During the pumping cycle, the valve acts

as a Backpressure Control Valve. When pump discharge pressure

falls below an adjustable minimum, the valve modulates toward a

closed position, increasing backpressure against the pump. Throttling

(Backpressure) action is controlled by a normally closed control pilot

designed to: 1) Open (allowing fluid out of the main valve cover cham-

ber) when pump discharge pressure is above the adjustable setpoint,

and, 2) Close (allowing fluid to fill the main valve cover chamber

through the integral orifice of the Accelerator Pilot) when pump dis-

charge pressure is below the adjustable setpoint. An increase in pump

discharge pressure causes the valve to modulate toward an open

position. A decrease in pump discharge pressure causes the valve to

modulate toward a closed position.

1

XX

Y/FC

2

3

5

6

7

6

8

XX

4(L)

CLOSES VALVE

OPENS VALVE

FLOW

Installation

1. Prior to installation, flush line to remove debris.

2. Install valve so the flow arrow matches flow through the line, and gauges to monitor valve inlet and outlet pressures.

3. Install isolation valves upstream and downstream of the main valve.

4. Provide adequate clearance for valve servicing and maintenance. Refer to valve servicing dimensions on next page. Avoid installing valves

6" and larger in the vertical position (main valve stem horizontal). Automatic Control Valves (ACVs) are designed for horizontal in-line instal-

lation, with the cover facing up (main valve stem vertical). Slow operation or premature stem and guide wear may occur if valve is not

installed according to factory recommendations. Consult factory for detailed engineering review prior to ordering if valve is to be installed

other than horizontally in-line.

5. If valve is equipped with a pilot control system, extra precautions should be made during installation to protect the piping circuit from dam-

age. Only remove the pilot control system from the valve if necessary. Tubing and fittings should be kept clean and replaced exactly as

removed. Consult appropriate hydraulic schematic to ensure proper re-assembly.

6. Connect solenoid wiring leads to desired switching device, using safe, standard electrical practices.

7. Install a pressure gauge at a location upstream of the valve.

8. After installation, vent entrapped air from valve cover and pilot system by following instructions on Technical Bulletin.

Start-up of an automatic control valve requires that proper procedures be followed. Time must be allowed for the valve to react to adjustments and the

system to stabilize. The objective is to bring the valve into service in a controlled manner to protect the system from damaging over-pressure.

Pump Shutdown: When the pump is signaled to turn off, the 3-Way

Solenoid is de-energized, venting the cover chamber of the 3-way

Accelerator Pilot. The Accelerator Pilot allows the main valve cover

chamber to be connected to upstream pressure, causing the valve to

close at a controlled rate. The valve slowly begins to close while the

pump continues to operate. The closing rate of the valve is controlled

by the adjustable closing speed control, which restricts the speed of

fluid and pressure entering the main valve cover chamber. When the

valve reaches the closed position, the limit switch is actuated, turning

the pump off.

Hydraulic Check Feature: When the pump is turned off and down-

stream pressure is greater than upstream pressure, downstream pres-

sure is admitted to the main valve cover chamber through a check

valve in the pilot control system, closing the valve, preventing reversal

of flow.

Manual Operation: Engaging the Solenoid Manual operator simulates

power to the solenoid, manually opening the main valve. Disengaging

the Solenoid Manual operator returns the valve to the closed position.

1 – Main Valve (905GD – Single Chamber)

2 – Pressure Sustaining Control

3 – Model 22 Accelerator Control

4 – Limit Switch

5 – 3-Way Solenoid

6 – Check Valve

7 – Adjustable Opening Speed

8 – Adjustable Closing Speed

X – Isolation Cocks

Y – Y-Strainer