CONTENTS

Technical Specification

Important Notes to Service Engineers

FD-5 Maintenance and Alignment Information

Exploded View 1

Exploded View 2

Circuit Board Views

Alignment Instructions

FD-5 Control Board Schematic Diagram

Cabinet Drawing &Parts List

CPU/Switch/Battery P.C.B.'s

Memory/Fuse/Volume P.C.B.'s

Modem P.C.B. Component Layout

Keyboard Schematic Diagram

Chassis Schematic Diagrams

Power Supply Schematic Diagram

Modem Chassis Schematic Diagrams

Electrical Parts List

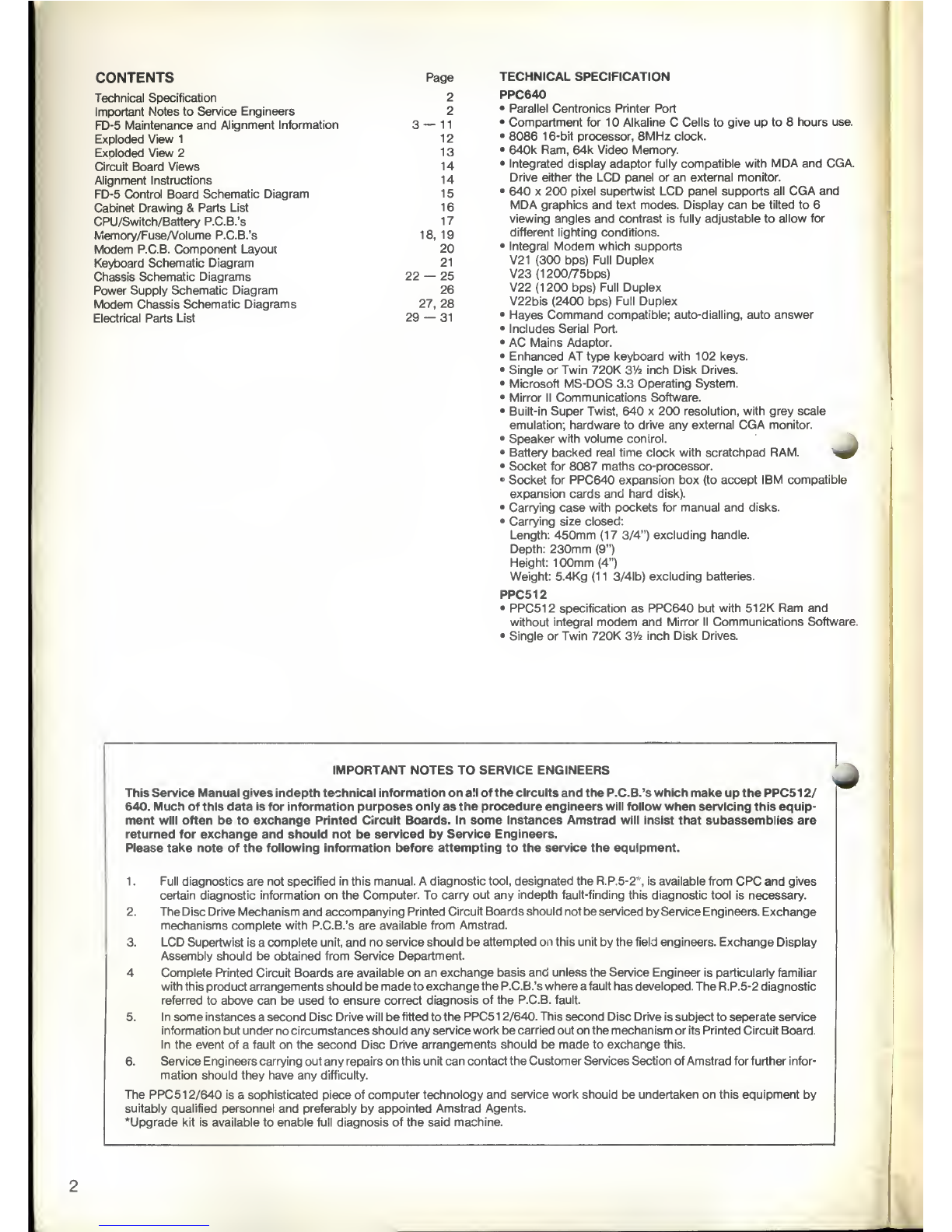

Page TECHNICAL SPECIFICATION

2PPC640

2•Parallel Centronics Printer Port

3—11 •Compartment for 1Alkaline CCells to give up to 8hours use.

1

2

•8086 16-bit processor, 8MHz clock.

13 •640k Ram, 64k Video Memory.

14 •Integrated display adaptor fully compatible with MDA and CGA.

14 Drive either the LCD panel or an external monitor.

1

5

•640 x200 pixel supertwist LCD panel supports all CGA and

1

6

MDA graphics and text modes. Display can be tilted to 6

1

7

viewing angles and contrast is fully adjustable to allow for

18, 19different lighting conditions.

20 •Integral Modem which supports

21 V21 (300 bps) Full Duplex

22 —25 V23 (1 200/75bps)

26 V22 (1200 bps) Full Duplex

27, 28 V22bis (2400 bps) Full Duplex

29 —31 •Hayes Command compatible; auto-dialling, auto answer

•Includes Serial Port.

•AC Mains Adaptor.

•Enhanced AT type keyboard with 102 keys.

•Single or Twin 720K 31/2 inch Disk Drives.

•Microsoft MS-DOS 3.3 Operating System.

•Mirror II Communications Software.

•Built-in Super Twist, 640 x200 resolution, with grey scale

emulation; hardware to drive any external CGA monitor.

•Speaker with volume control.

•Battery backed real time clock with scratchpad RAM. -^0

•Socket for 8087 maths co-processor.

•Socket for PPC640 expansion box (to accept IBM compatible

expansion cards and hard disk).

•Carrying case with pockets for manual and disks.

•Carrying size closed:

Length: 450mm (1 73/4") excluding handle.

Depth: 230mm (9")

Height: 100mm (4")

Weight: 5.4Kg (1 13/4lb) excluding batteries.

PPC512

•PPC512 specification as PPC640 but with 51 2K Ram and

without integral modem and Mirror II Communications Software,

•Single or Twin 720K 31/2 inch Disk Drives.

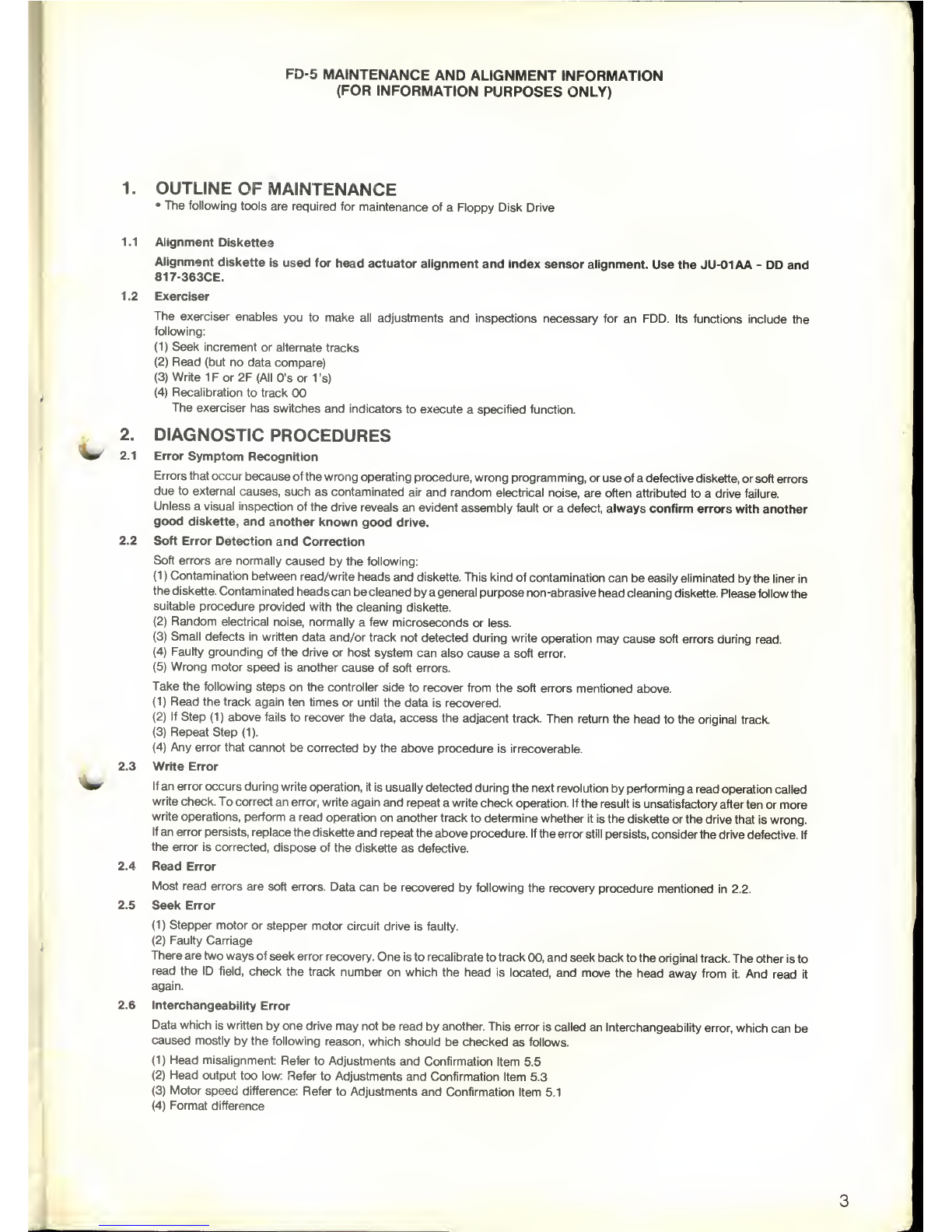

IMPORTANT NOTES TO SERVICE ENGINEERS

This Service Manual gives indepth technical information on all of the circuits and the P.C.B.'s which make up the PPC51 2/

640. Much of this data is for information purposes only as the procedure engineers will follow when servicing this equip-

ment will often be to exchange Printed Circuit Boards. In some instances Amstrad will insist that subassemblies are

returned for exchange and should not be serviced by Service Engineers.

Please take note of the following information before attempting to the service the equipment.

1

.

Full diagnostics are not specified in this manual. Adiagnostic tool, designated the R.P.5-2*, is available from CPC and gives

certain diagnostic information on the Computer. To carry out any indepth fault-finding this diagnostic tool is necessary.

2. The Disc Drive Mechanism and accompanying Printed Circuit Boards should not be serviced by Service Engineers. Exchange

mechanisms complete with P.C.B.'s are available from Amstrad.

3. LCD Supertwist is acomplete unit, and no service should be attempted on this unit by the field engineers. Exchange Display

Assembly should be obtained from Service Department.

4Complete Printed Circuit Boards are available on an exchange basis and unless the Service Engineer is particularly familiar

with this product arrangements should be made to exchange the P.C.B.'s where afault has developed. The R.P.5-2 diagnostic

referred to above can be used to ensure correct diagnosis of the P.C.B. fault.

5. In some instances asecond Disc Drive will be fitted to the PPC-51 2/640. This second Disc Drive is subject to seperate service

information but under no circumstances should any service work be carried out on the mechanism or its Printed Circuit Board.

In the event of afault on the second Disc Drive arrangements should be made to exchange this.

6. Service Engineers carrying out any repairs on this unit can contact the Customer Services Section of Amstrad for further infor-

mation should they have any difficulty.

The PPC51 2/640 is asophisticated piece of computer technology and service work should be undertaken on this equipment by

suitably qualified personnel and preferably by appointed Amstrad Agents.

'Upgrade kit is available to enable full diagnosis of the said machine.