pen as with typical felt pen type recorders. Chart ranges and scales are factory programmed, per applicable

PMO requirements, but may easily be re-ranged in the field. Charts are plain paper, and pre-printed only

with circular ring divisions. Division spacing meets PMO requirements. User defined scales and chart

ranges are printed in one of four available colors.

1.3.5. Cold Product Record - Control

The AV-9900 may be configured to receive an input from an RTD, or mA transmitter, measuring the Cold

Product temperature as it exits the pasteurization loop. This function may be specified at time of order, or

upgraded in the field at a later date. A factory set, field modifiable scale has been programmed for the

recording pen. Data will be recorded in color allowing easy interpretation when reviewing chart

information.

An additional option exists for controlling the Cold Product Cooling within the AV-9900. An optional

PID Loop Control function can be specified at time of order, or upgraded at a later date in the field. This

function will receive its input from the same probe measuring the Cold Product temperature. In turn, a

desired set-point may be programmed, with output signals interfacing to the cooling loop. The PID, or

control functions, will vary the resulting output signal based on rising above or falling below the desired

Cold Product set-point.

1.3.6. Hot Water Loop Control

The AV-9900 may be configured to receive an input from an RTD, or mA transmitter, measuring the Hot

Water Loop temperature. This function may be specified at time of order, or upgraded in the field at a later

date. In turn, a desired set-point may be programmed, with output signals interfacing to the Hot Water

Loop. The PID, or control functions, will vary the resulting output signal based on rising above or falling

below the desired Hot Water set-point.

If various products are being processed, up to five Hot Water Controllers are available (one for each STLR

diversion set-point). Each controller may have it’s own set-point and PID tuning parameters. When the

operator selects a new STLR diversion set-point, the corresponding Hot Water Controller is automatically

selected. Again, Hot Water Control set-points and PID tuning parameters would have been pre-

programmed

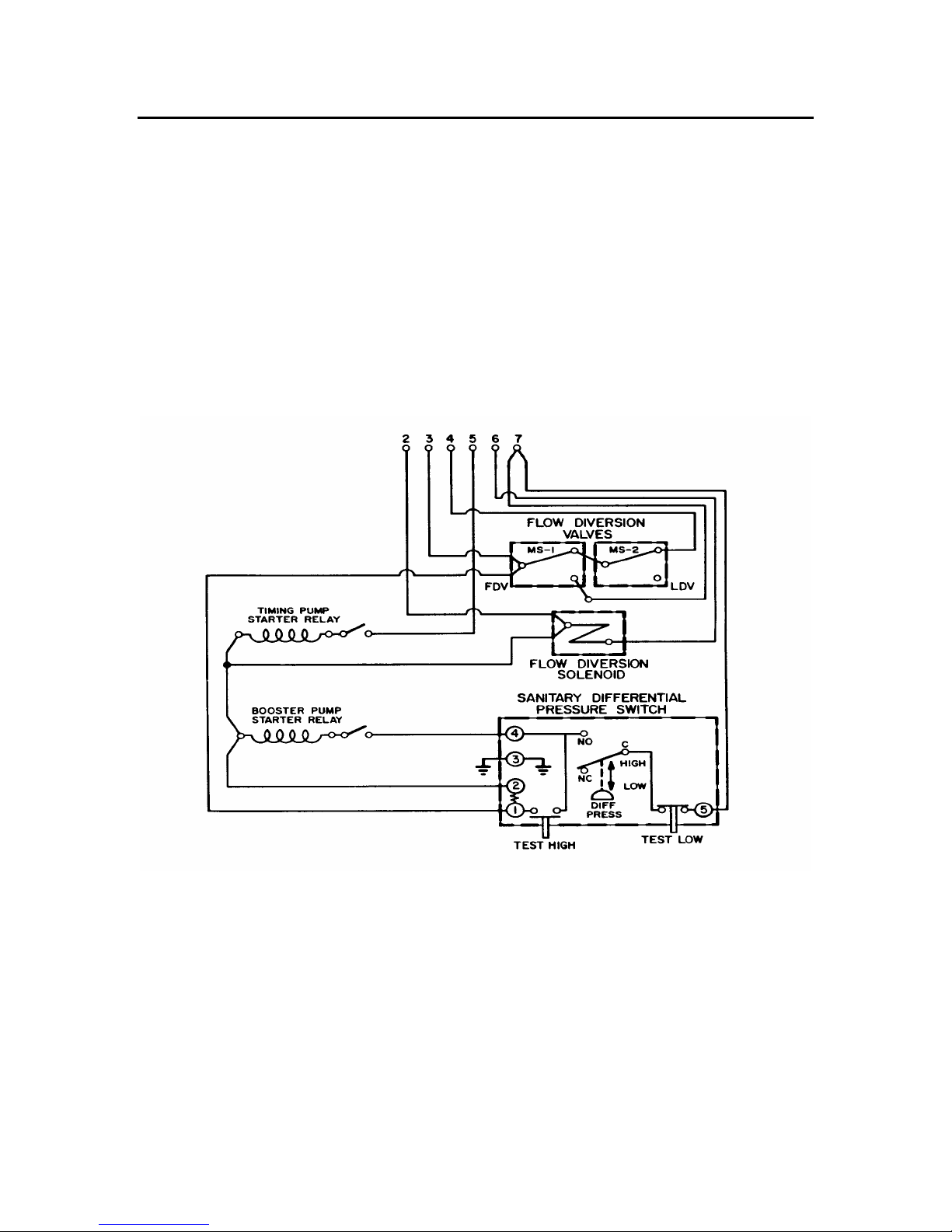

1.3.7. Safety Flow Limit Record - Control

The AV-9900 may be configured to receive an input from a Sanitary Flow Meter for the purpose of

controlling the pasteurization loop flow rate via Meter Based Timing. This function may be specified at

time of order, or upgraded in the field at a later date. A factory set scale has been programmed for the

recording pen per FDA (Food & Drug Administration) guidelines. Data will be recorded in color allowing

easy interpretation when reviewing chart information. In addition to the recorded flow rate on the chart, an

event pen is also present on the outer chart area. This event pen indicates when the system has gone below

“Loss of Signal” setpoint, “High Flow” setpoint or is in proper flow. These alarm conditions directly

switch on-board mechanical relays. Contacts of the relays interface with the Legal Flow Control unit,

allowing for auto system divert in the event of an alarm condition.

An optional PID Loop Control function can be specified at time of order, or upgraded at a later date in the

field. This function will receive its input from the same flow meter signal feeding the recording pen. In

turn, a desired set-point may be programmed, with output signals interfacing to the pump controlling the

system flow rate. The PID, or control functions, will vary the resulting output signal based on rising above

or falling below the desired Flow Rate set-point.

Revision 3.0 Section 1 3