Apex Digital XA1200 User manual

www.apexseeder.com

Erosion Control Products Corporation

9599 Nanticoke Business Park Drive

Greenwood, DE 19950

513-642-0147

XA1200 Operations Manual

Operations Manual

Parts Manual

Frame

Engine Base ........................................................................................................................................................48

Engine Bay Ribs .................................................................................................................................................49

Engine Bay Side Panels .....................................................................................................................................51

Engine Bay Platforms .........................................................................................................................................52

Engine Bay Doors ............................................................................................................................................... 53

Railing - Left Side ...............................................................................................................................................54

Railing - Right Side .............................................................................................................................................56

Railing - Front .....................................................................................................................................................58

Ladder Access ....................................................................................................................................................59

Ladder Access Gate ...........................................................................................................................................61

Tool Box ..............................................................................................................................................................62

Slurry Tank

Agitator ...............................................................................................................................................................63

Slurry Tank Lid ....................................................................................................................................................65

Tank Hatch Attachment ....................................................................................................................................... 66

Tank Hatch Latches, Handle, and Vent ...............................................................................................................67

Tank Fill ...............................................................................................................................................................69

Drain Pipe ...........................................................................................................................................................71

Boom ..................................................................................................................................................................72

Boom Feed .........................................................................................................................................................74

Slurry Pump ........................................................................................................................................................76

Engine

Fuel Tank ............................................................................................................................................................78

Engine, Radiator, and Fuel Filter Attachment .....................................................................................................80

Drive Pump and Coupler ....................................................................................................................................82

Radiator and CAC Tubes .................................................................................................................................... 84

Engine Air Intake and Exhaust ............................................................................................................................85

Exhaust Bracket ..................................................................................................................................................87

Radiator Fan .......................................................................................................................................................88

Coolant Recovery Tank .......................................................................................................................................89

Hydraulics

Hydraulic Tank ....................................................................................................................................................90

alve Manifold and Hydraulic Oil Filter .................................................................................................................92

Electrical

Battery ................................................................................................................................................................94

Engine Control Unit and MC41 ...........................................................................................................................95

Control Box .........................................................................................................................................................97

Strobe Light ........................................................................................................................................................99

Horn ..................................................................................................................................................................100

Tower Harness Clamp ..................................................................................................................................... 101

Tool Kit ..............................................................................................................................................................102

Hoses

Hydraulic Tank ..................................................................................................................................................103

Drive Pump .......................................................................................................................................................105

Valve Manifold and Filter ..................................................................................................................................107

Agitator Motor ...................................................................................................................................................109

Slurry Pump Motor ............................................................................................................................................110

Slurry Discharge Hose ...................................................................................................................................... 111

Fuel Tank ..........................................................................................................................................................112

Fuel Filter and Engine .......................................................................................................................................114

Options

Straight Pull Trailer

Hitch Attachment ...............................................................................................................................................115

Hitch ..................................................................................................................................................................116

Undercarriage Attachment ................................................................................................................................ 118

Fenders .............................................................................................................................................................119

Rear Bumper ....................................................................................................................................................121

Junction Box - Slurry Tank ................................................................................................................................123

Junction Box - Engine Base ..............................................................................................................................124

Goose Neck Trailer

Deck Attachment ...............................................................................................................................................125

Deck Railing ......................................................................................................................................................126

Trailer Jack .......................................................................................................................................................128

Safety Chains and Breakaway Switch ..............................................................................................................130

Undercarriage Attachment ................................................................................................................................131

Fenders .............................................................................................................................................................132

Rear Bumper ....................................................................................................................................................134

Junction Box - Slurry Tank ................................................................................................................................136

Junction Box - Engine Base ..............................................................................................................................137

Tool Box ............................................................................................................................................................138

Hose Reel

Hose Reel Attachment ......................................................................................................................................139

Hose Rollers and Retainer ................................................................................................................................140

Slurry Hose and Pin Lock .................................................................................................................................142

Control Box .......................................................................................................................................................143

Motor .................................................................................................................................................................144

Nozzle Kit ..........................................................................................................................................................145

Hoses

Motor to Platform Bulkhead ..............................................................................................................................146

Valve Manifold ..................................................................................................................................................147

Slurry Discharge Hose ...................................................................................................................................... 148

SB-105 XA1200 Program Update ...............................................................................................................................149

SB-117 XA1200 Agitator Paddle Gusset .....................................................................................................................153

Appendix A:Pages Index .............................................................................................................................................157

Appendix B:Parts Index ...............................................................................................................................................158

3

2. CONDITIONS FOR WARRANTY APPLICATION

The application of the limited warranty is conditional upon the following:

•Provide Apex with your copy of the Warranty Registration Card received at the time of

purchase or register your machine online at www.apexseeder.com.

•Note: In instances where there are discrepancies relating to the date of purchase, Apex

reserves the right to deny and/or charge back any warranty costs incurred outside the

original warranty period.

•Provide proof (upon demand) that operational and maintenance guidelines specified in

the Apex technical publications were and are being respected.

•Vehicle servicing must be performed by an authorized Apex Service Department or a

service provider assigned by an authorized Apex agent.

•Return defective component with warranty tag to the Warranty Department within 30 days

of the repair date.

•This limited warranty covers only new items manufactured by Apex. It does NOT extend

to any used or rebuilt item, unless the sales order or contract for such item expressly

provides for warranty coverage.

3. OEM WARRANTY

Parts which are manufactured by vendors or suppliers other than Apex, but sold by Apex, as part

of an Apex machine or sold as a repair or replacement part of the Apex machine, are warranted

to the limits of that manufacturer’s product warranty.

4. Base Warranty

Apex will repair and/or replace, at its discretion, all failures resulting from defects in material,

design or workmanship for the first 12 months or 1,000 hours from the in-service date of the

product

.

5. Extended Warranty

Apex will repair and/or replace, at its discretion, failures resulting from defects in material, design

or workmanship related to the powertrain components, frame and hydraulic components

excluding hoses, seals and O-rings.

6.WARRANTY TRANSFER

The warranty described here and above is transferable to subsequent owner(s) for remainder of

warranty period from original in-service date.

7. EXCLUSIONS – ARE NOT WARRANTED

•Engine, battery (Warranted to the limits of that manufacturer’s product warranty.)

•Normal wear on all components (such as sprockets, tires, engine belt, etc.)

•Replacement parts and/or accessories that are not genuine Apex parts and/or

accessories.

•Damage resulting from installation of parts other than genuine Apex parts.

•Damage caused by failure to provide proper maintenance as detailed in Apex technical

publications.

•The costs of regular maintenance services including, but not limited to tune-ups,

adjustments, parts, and lubricants. All optional accessories (as well as damages caused

by optional accessories) installed on the machinery by any facility/shop other than Apex.

4

•Damage resulting from but not limited to accidents, water intrusion, fire, misuse, abuse or

neglect.

•Damage resulting from but not limited to operation of the machine in conditions

incompatible with machine design as defined in the vehicle Operator’s or

Operator’s/Service Guide.

•Damage resulting from modification to the vehicle not approved in writing by Apex.

•Indirect or consequential losses incurred by the owner of the machine including but not

limited to: travel time and mileage required for servicing a Apex product, transportation,

towing or test drive, telephone/cellular calls and all electronic communications, taxis,

rental or substitute vehicle, cost of service calls or any other incidental or consequential

damages.

•Damage or breakdown resulting from improper or inadequate storage by owner.

•Vehicle delivery inspections.

8. LIMITATIONS OF LIABILITY

THIS WARRANTY IS EXPRESSLY GIVEN AND ACCEPTED IN LIEU OF ANY AND ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATIONS ANY

WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE TO THE

EXTENT THAT THEY CANNOT BE DISCLAIMED.

THE IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE LIFE OF THE EXPRESS

WARRANTY, INCIDENTAL AND CONSEQUENTIAL DAMAGES ARE EXCLUDED FROM

COVERAGE UNDER THIS WARRANTY.

No other person has been authorized to make any affirmation, representation or warranty other

than those contained in this warranty, and if made, such affirmation, representation or warranty

shall not be enforceable against Apex. Apex reserves its right to modify this warranty policy at

any time, being understood that such modification will not alter the warranty conditions applicable

to vehicles sold while this warranty is in effect.

6

TABLE OF CONTENTS

General Information

Equipment Description…………………………………………………………………………8

Reference Information………………………………………………………………………….9

Orientation……………………………………………………………………………………….9

Safety

Safety Information………………………………………………………………………………10

Safety Symbols and Definitions……………………………………………………………….10

Safety Decals…………………………………………………………………………………...11

Prior to Operation………………………………………………………………………………12

General Precautions……………………………………………………………………………12

Welding Precautions…………………………………………………….…………………….14

Operation Safety/ The Operator………………………………………………………………15

Sound Levels/ Hearing Protection…………………………………………………..15

Avoid Power Lines…………………………………………………………………….15

Discharge Electrocution……………………………………………………………….15

Operator Protection……………………………………………………………………16

Tow Vehicle…………………………………………………………………………….16

Battery Safety………………………………………………………………………………..…16

Batter Handling Safety………………………………………………………………..17

Fire Prevention………………………………………………………………………………….17

Short Term Storage…………………………………………………………………………....17

Long Term Storage…………………………………………………………………………….18

Engine Storage………………………………………………………………………...18

Disposal Procedure……………………………………………………………………18

Hauling and Towing…………………………………………………………………………….18

Safety While Refueling…………………………………………………………………………18

Pre-Operation Inspections………………………………………………………………….19

Daily Pre-Operation Checklist…………………………………………………………………20

Daily Checks……………………………………………………………………………20

Weekly Checks………………………………………………………………………...20

Re-Filling Fuel………………………………………………………………………….20

Engine Oil Level………………………………………………………………………..21

Engine Coolant Level………………………………………………………………….21

Hydraulic Fluid Level…………………………………………………………………..22

Fuel/ Water Separator…………………………………………………………………22

Lighting………………………………………………………………………………….23

Training………………………………………………………………………………………….23

General Operator Safety Guidelines…………………………………………………………23

Applicator Preparation and Maintenance…………………………………………………….24

Preventative Maintenance……………………………………………………………………..25

Safety While Maintaining………………………………………………………………………25

7

Operator Station and Controls

Entering and Exiting the Operator Station…………………………………………………..25

Machine Controls………………………………………………………………………………25

Controller Master Display…………………………………………………………………25

Home Screen………………………………………………………………………………26

Pump Control………………………………………………………………………………26

Engine Screen……………………………………………………………………………..26

Outputs/ Diagnostics Screen……………………………………………………………..26

Service Intervals Screen………………………………………………………………….27

Screen Settings……………………………………………………………………………27

Agitator Control…………………………………………………………………………….27

Horn…………………………………………………………………………………………27

Ignition Switch……………………………………………………………………………...28

Starting Procedure……………………………………………………………………………..28

Pre-Operation Warm-Up………………………………………………………………………28

Starting with Jumper Cables………………………………………………………………….29

Stopping the Engine…………………………………………………………………………...30

Operating Instructions………………………………………………………………………31

Purge and Clean…………………………………………………………………………..31

Mixing Materials……………………………………………………………………………32

Application of Product…………………………………………………………………………33

Determine Application Rate………………………………………………………………33

Application from Discharge Boom………………………………………………………..34

Application from Hose Reel (if equipped)……………………………………………….35

Extension Hose System - Without Remote Valve……………………………………..36

Hose Work with Radio Transmitter (if equipped)……………………………………….37

Reloading Procedure………………………………………………………………………37

Cleaning and Maintenance……………………………………………………………………37

Daily Cleaning the Applicator……………………………………………………………..37

Maintenance…………………………………………………………………………………..38

Fluid Capacity Chart………………………………………………………………………38

Engine Oil…………………………………………………………………………………..38

Engine Fuel…………………………………………………………………………………38

Hydraulic Oil………………………………………………………………………………...39

Engine Coolant……………………………………………………………………………..39

Fuel/ Water Separator……………………………………………………………………..39

Engine Air Filter…………………………………………………………………………….40

Lubricating Grease…………………………………………………………………………40

Fuse Panel………………………………………………………………………………….41

Hydraulic Filter Restriction Indicator……………………………………………………..41

Applicator Dimensions…………………………………………………………………………42

Skid Type……………………………………………………………………………………42

Straight Tow Option………………………………………………………………………..43

Gooseneck Tow Option……………………………………………………………………44

Maintenance Chart……………………………………………………………………………..45

8

EQUIPMENT DESCRIPTION

The Apex XA1200 is a self-contained applicator. The Apex XA1200 Applicator is used

to apply liquid-based materials to any commercial, residential, mining sites, landfills, golf

courses, rail lines, oil/gas wells and lines; as well as any locations where a liquid-based

material is required. The Apex XA1200 Applicator is used to mix and apply dust control

palliative, all types of hydraulic mulches (wood and paper and blends), BFM (Bonded

Fiber Matrix), ADC (Alternative Daily Cover), and all types of seeds, fertilizers and lime.

The Apex XA1200 Applicator uses a fifteen (15) blade hydraulically-driven agitator

within the tank that is variable speed and reversible. The mixing system is engineered to

quickly blend the thickest materials used in the industry. The Apex XA1200 Applicator’s

stainless steel tank provides many years of corrosion-resistance when cleaned after

every use. The Apex XA1200 Applicator’s vortex slurry pump will discharge a variety of

materials at distances up to 185 feet (56 meters) without modification to the pump or

adjusting the mixing instructions and is engineered to allow the complete emptying of the

mixing tank. The primary components include:

Controls

Structure (includes slurry tank, railing and hatch)

Pump and discharge Assembly

Hose Reel Assembly

Discharge Boom Assemblies

Engine and Radiator

Hydraulic Agitator System

9

REFERENCE INFORMATION

Each Apex XA1200 Applicator has an identification plate with its model number, serial

number, and other related information. This plate is located on the left-hand side of the

unit, from the operator’s perspective. Use the serial number on this plate to identify the

most applicable version of the operator’s manual.

Model __________________________________________________

Serial Number ____________________________________________

Orientation

For the sake of this manual, the front of the machine is the side with the trailer hitch. The

rear of the machine is equipped with a ladder. The left, right, top and bottom are

referenced from the operator’s position facing the front of the machine, with his back

towards the side with the ladder.

ID Tag

10

SAFETY INFORMATION

Safety alert symbols are used throughout this manual to draw your attention to possible

dangers. These symbols and their explanations deserve your careful attention and

understanding. The safety warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper preventive measures.

These safety instructions are not meant to cover every possible condition that may

occur.

SAFETY SYMBOLS & DEFINITIONS

This symbol, the industry’s “Safety Alert Symbol”, is used

throughout this manual and on labels on the Applicator

itself to warn of the possible dangers that may lead to

personal injury. Read these instructions carefully. It is

essential for your safety that you read the instructions and

safety regulations BEFORE you attempt to transport,

assemble or operate this unit.

The word DANGER, preceded by the safety alert

symbol, indicates immediate hazards which WILL

result in severe personal injury or death if not avoided.

The word WARNING, preceded by the safety alert

symbol, indicates hazards or unsafe practices which

COULD result in severe personal injury or death if not

avoided.

The word CAUTION, preceded by the safety alert

symbol, indicates hazards or unsafe practices which

COULD result in minor personal injury if not avoided.

The word CAUTION, not preceded by the safety alert

symbol, indicates hazards or unsafe practices which

COULD result in equipment damage if not avoided.

The word NOTICE not preceded by the safety alert

symbol, indicates information or a company policy

that relates directly or indirectly to the safety of

personnel or the protection of property.

SAFETY DECALS

Make certain that all of the safety decals on the unit are maintained in good legible

condition. Replacement decals are available through Apex. Specify the part number

that is provided in the lower right hand corner of the decal.

11

12

PRIOR TO OPERATION

•Read this manual in its entirety and follow ALL safety procedures

•Check all lubrication points and fluid levels. See page- for specific lubrication

points and fluid specifications.

•Inspect all fasteners for tightness with the power turned off.

Obey all of the safety labels on the applicator. They are provided for your protection. If

any labels are removed, damaged or made unreadable in any way, contact Apex for a

replacement.

If the applicator is equipped with any options, read and understand ALL of the safety

precautions and warnings for that particular option BEFORE performing maintenance or

operating.

GENERAL PRECAUTIONS

1. Empty the tank daily to prevent stored material from producing

hazardous gases. Some gases produced by stored material

can be harmful or deadly.

2. Never enter the tank of the applicator before performing the

proper lockout/ tagout procedure. Use lockout/ tagout

procedure 29CFR1910.147 during inspection or maintenance.

3. Tag the engine operating area to show that the applicator is

being serviced. Use lockout/ tagout procedure

29CFR1910.147 during inspection or maintenance.

4. Stop all action, read and observe the operation and safety

manual in its entirety, following all safety precautions before

operating or performing maintenance.

5. Do not operate the applicator without all guards in place.

Always use safe operating practices.

6. Hydraulic fluid is under high pressure. Always use safe

operating procedure.

7. Keep a sufficient distance away from all electrical power lines.

13

8. Operators of the applicator should never ride on the machine

at speeds greater than 5 mph (8 kmh).

9. Always wear safety goggles when operating the applicator.

Other safety attire such as safety shoes, ear protection,

gloves, hard hats, dust masks, etc, should be worn as required

by warning decals on the machine, in the operator’s manual or

specific job site requirements. Avoid loose fitting clothing that

may get caught in rotating machinery. Remove watches, rings

etc.

10. Do not load the applicator while in transit. Load only when

parked and unit is as level as possible. Take care not to drop

foreign objects into the tank, such as pens, lighters, etc, as the

objects could plug the slurry system. Should any object be

dropped into the tank, DO NOT reach into the tank to retrieve

the object. See the Maintenance section before allowing any

personnel to enter the tank.

11. Make sure the area to be sprayed is clear of all persons and

animals.

12. The driver of the carrying or towing vehicle is responsible for

the safety of the operator(s) of the applicator. Make sure the

driver is aware and avoids all possible hazards to the

operator(s), such as low tree limbs, low power lines, etc.

Vehicles on which the applicator is mounted must be stopped

and started gradually. Avoid abrupt starts and stops. Never

operate on a slope or a hill that may endanger the driver and/

or the operator(s). All personnel should review and be familiar

with stop and start signals between the driver and the

operator(s) before going into operation. Only the operator

should be located on the platform during operation.

13. Never operate this or any other machine when fatigued, tired,

under the influence of alcohol, illegal drugs or medication. All

personnel must be in good physical and mental condition to

operate this applicator.

14. Use proper means (steps, ladder) for mounting and

dismounting of the applicator. Never mount or dismount a

moving machine.

14

WELDING PRECAUTIONS

Never perform welding on the XA1200 without disconnecting the following items:

•Move the engine ignition switch to the OFF position.

•Disconnect the Apex display by disconnecting the connector on the bottom of the

Operator Control Box.

•Disconnect the battery, located on the right side of

the unit, behind the engine door.

1. Remove the positive battery cable from the battery.

15

•Disconnect the engine Apex microcontroller. Locate the microcontroller plug,

above the battery.

1. Slide the red button (item 1) to the left.

2. Depress the button (item 2) to allow the

clasp to raise.

3. Raise the clasp to remove the controller

connector.

•Disconnect both connectors on the engine ECU.

1. Depress item 1 to allow the clasp (item 2) to raise.

2. Raise the clasp to remove the connector from the Microcontroller.

OPERATION SAFETY/ THE OPERATOR

Sound Levels/ Hearing Protection

The noise level of the applicator at the operator station, unshielded, is 86dBA.

Take the following precautions:

•Always keep doors and windows of the tow vehicle closed.

•Use ANSI S3 19-1975 approved hearing protectors with a noise reduction rating

(NPR) of 25dB (A).

•Ear plugs (disposable or re-useable)

Avoid Power Lines

Serious injury or death can result from contact with electric lines. Never

move any part of the equipment closer than 10 ft (3 meters) plus twice

the line insulator length to an electric line. Use a signal person to guide

the operator. Use shrouds or insulators as necessary.

Discharge Electrocution

Do not aim the discharge spray toward power lines, transformers or

other high voltage electrical conductors. Also, do not aim the discharge

spray towards people, animals or anything other than the intended

application area.

1

2

3

16

Operator Protection

The following precautions are recommended for operator protection. Always follow

safety regulations and certifications for your specific industry.

•Wear ANSI approved protective eyewear such as safety glasses, goggles, and

face shield.

•Wear ANSI approved hard hat.

•Wear appropriate ear protection.

•Steel toe shoes are an excellent safeguard for anyone on or around machinery.

•Improper operation and failure to follow safety precautions can cause serious

injury or death. All personnel must be clear of the hazard zone while the

applicator is in operation.

Tow Vehicle

Ensure that the tow vehicle has the capacity to

control the fully-loaded XA1200. See pages 40-42

for applicator weights.

It is the operator’s responsibility to ensure the tow vehicle is properly maintained,

including safety lighting and notifications. Do not use a tow vehicle before properly

testing the road-worthiness.

•Tire Pressure

•Functioning traffic lights

•Properly attached

•Break-Away Switch

•Tongue weight

BATTERY SAFETY

•Battery electrolyte contains sulphuric acid and can quickly burn the skin and eat

holes in clothing. If you spill acid on yourself immediately flush the area with water.

•Battery acid could cause blindness if splashed into the eyes. If acid gets into the

eyes, flush them immediately with large quantities of water and see a doctor at once.

•If you accidentally ingest battery acid, drink a large quantity of water or milk. Call a

doctor or hospital immediately.

•When working with batteries ALWAYS wear safety goggles.

•Batteries generate hydrogen gas. Hydrogen gas is very explosive and is easily

ignited with a small spark or flame.

17

•Before working with batteries turn the key switch to the OFF position.

•Avoid short circuiting the battery terminals through accidental contact with metallic

objects, like tools, across the terminals.

Battery Handling Safety

When removing or installing, check which is the negative and positive terminal.

Removing Batteries:

1. Disconnect the (-) terminal connected to the ground wire.

2. Disconnect the (+) terminal connected to the starter

When installing the batteries, follow this procedure in reverse order.

3. Tighten the battery terminals securely; check that the terminals are not lose by

trying to move the cables by hand. Loosened cables can generate sparks and lead

to an explosion.

FIRE PREVENTION

•Remove all fiber mulch, leaves, paper and other flammable material accumulated in

the engine compartment or other places on the Applicator. This could cause a fire.

•Marshland, when dry, is highly flammable. Marshland can self-ignite even in low

temperatures. Always keep the engine compartment and engine clean.

•Check fuel, lubrication and hydraulic system for leaks. Have any leaks repaired

immediately. Clean up any excess oil, fuel or other flammable fluids and dispose of

properly.

•Be sure the fire extinguisher is present and working. The fire extinguisher is located in

the cab, on the left hand side of the operators seat.

SHORT TERM STORAGE

1. Drain the slurry tank of all water and material prior to storage and leave the drain

plug uninstalled.

Hydroseed material can produce gases that are

harmful or deadly if inhaled. Empty the slurry tank

daily to prevent build-up of these gases.

Do not store material for long periods of time in

the slurry tank. Harmful or deadly gases could

result.

18

LONG TERM STORAGE

1. Drain the slurry tank of all water prior to storage and leave the drain plug uninstalled.

2. If possible, cover the machine with a tarp or park inside an enclosure.

3. Store the Applicator with all of the slurry valve handles in the open position. To

prevent damage from freezing, remove all of the slurry valves and store in a heated

area.

4. Pour 1 Qt. (0.95 L) of mineral oil or environmentally safe lubricant into the pump

housing and spin the pump to prevent rust in the pump. Remove the drain plug.

5. Lubricate all fittings.

6. Check the antifreeze in the radiator and add as necessary.

7. Lubricate the equipment again just prior to putting back into operation after having

been in storage.

8. Change hydraulic oil and filter (500 hours).

9. Disconnect the battery cables. In cold weather, remove the battery and store it in a

safe, warm place.

10. Add fuel stabilizer to the fuel tank.

ENGINE STORAGE

The long term storage of an engine without adequate preparation will cause damages to

external as well as internal components. Refer to the engine manufacturer

documentation for the appropriate storage procedure.

DISPOSAL PROCEDURE

•Do not discard into municipal waste stream.

•Disassemble and contain hydraulic components in approved container.

•Discard through a licensed processing facility.

HAULING AND TOWING

The following items should be checked before towing the applicator. These safety items

are in place to protect personnel during operation as well as during transportation

between jobsites.

•Inspect the hitch for signs of corrosion or loose hardware. Replace any suspect or

missing components immediately.

•Inspect the safety chains for signs of corrosion or defects. Replace any suspect

components immediately.

•Check that all turn signals and brake lights are functioning properly. Correct any non-

functioning lights immediately.

•Check the trailer brakes and breakaway switch are working properly.

•Check tires for proper inflation (110 psi).

19

Operating or towing the XA1200 with faulty safety

devices is extremely dangerous. Failure to correct any

of these components could result in severe personal

injury or death.

SAFETY WHILE REFUELING

Diesel fuel is flammable and explosive under certain circumstances. Observe these

safety practices:

•Always handle fuel in a well-ventilated area.

•Do not smoke or allow open flames or sparks in the vicinity.

•Do not refuel with the engine hot or running.

•Avoid physical contact with diesel fuel.

•Regularly inspect fuel system components.

•If fuel or fumes are noted while operating the XA1200, the cause should be

determined immediately.

•Never open the fuel lines or loosen the injectors if the applicator runs out of fuel.

•Avoid inhalation of exhaust particulate dust. Wear a dust mask. If respiratory

irritation or discomfort occurs, leave the dusty area. Utilize breathing assistance or

oxygen if necessary,

•Elevated concentrations of metals in the form of dust, soot, and contaminates are

contained in these filters. Health regulations may exist for the materials found in

these filters such as Zinc, Molybenum, polynuclear aromatic sulfur, and iron.

•Proper disposal of the exhaust dust and filter are required. Dispose of in accordance

with local and environmental regulations.

•Diesel particulate filter maintenance MUST be completed by appropriately trained

personnel.

PRE-OPERATION INSPECTIONS

The Pre-Operation Inspection that an operator does before starting a piece of equipment

is the single most important responsibility of the day. The operator is the key component

in the walk-around and it is their responsibility to solicit help as required if areas of

distress or concern are noted. Cell phones and digital pictures are extremely helpful

when communicating potential problems or concerns.

Many operators overlook vital aspects of the walk-around such as fluid type and

quantity. To maximize the effectiveness of a fluid it must be the proper viscosity and

quality at starting temperatures. Next in degree of importance is the fluid quantity. Too

much fluid can be as harmful as too little fluid. Be sure all fluids are in the proper level

range and refer to the Fluid Specifications and Tank Capacities Chart on Page - of this

manual whenever replacing or adding fluids.

•The walk-around should be performed before each shift and before moving the

machine or even starting the engine.

20

•The following describe in detail the recommended items to be checked, whether

it is a daily check (every 8 hours) or a weekly check (every 40 hours).

Once the Pre-Operation Walk-Around is complete a final inspection should be done by

operating the applicator for a short period of time. Stop the unit and check the gauges

and display screen.

Daily Pre-Operation Checklist

Before operating the applicator it is important to inspect the following items for safety

and performance.

CHECK EVERY 8 HOURS (DAILY)

1. Refill Fuel

2. Check engine oil level

3. Check engine coolant level

4. Check hydraulic fluid level

5. Check fuel/ water separator

6. Verify that all lighting is in working order

7. Inspect that all railings are in place and secure

8. Inspect that all safety guards are in place

9. Inspect that the mixing tank is free from foreign objects

CHECK EVERY 40 HOURS (WEEKLY)

1. All Safety Decals

2. Safety Surfaces for wear

3. Check Hydraulic Hoses for any wear

4. Check engine air filter for clogs and debris

Re-Filling Fuel

Always use fresh diesel fuel when re-fueling the XA1200 Applicator. The fuel tank is

sized to allow for continuous work for 8 hours between fill-ups. The fuel tank fill is

located on the front of the unit, on the right side. The sight gauge is located on the side

of the fuel tank.

Fuel fill

Table of contents

Popular Seeder manuals by other brands

GREAT PLANES

GREAT PLANES NTS2607 Operator's manual

ARBOS

ARBOS MEK-X250 Use and maintenance manual

GREAT PLAINS

GREAT PLAINS YP-30 Series Operator's manual

Kubota

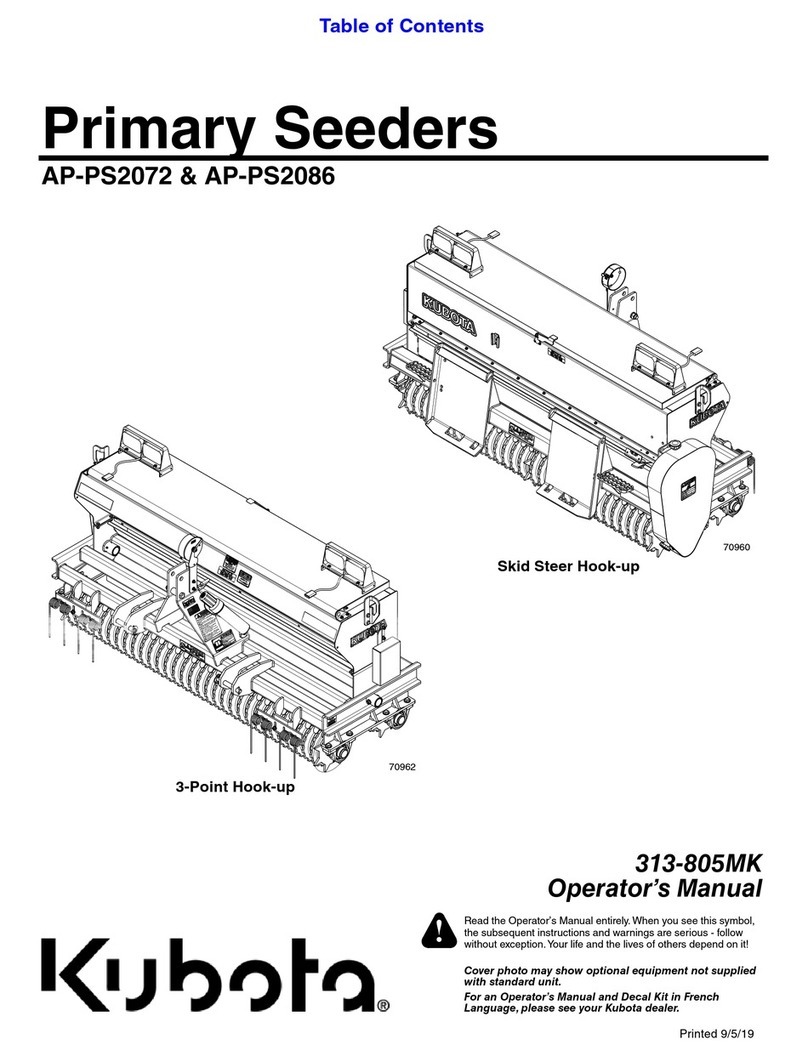

Kubota AP-PS2072 Operator's manual

PIEROBON

PIEROBON TD 21 Series OPERATOR'S MANUAL AND SPARE PARTS

Tiger

Tiger TANDEM Series OPERATOR'S MANUAL AND SPARE PARTS