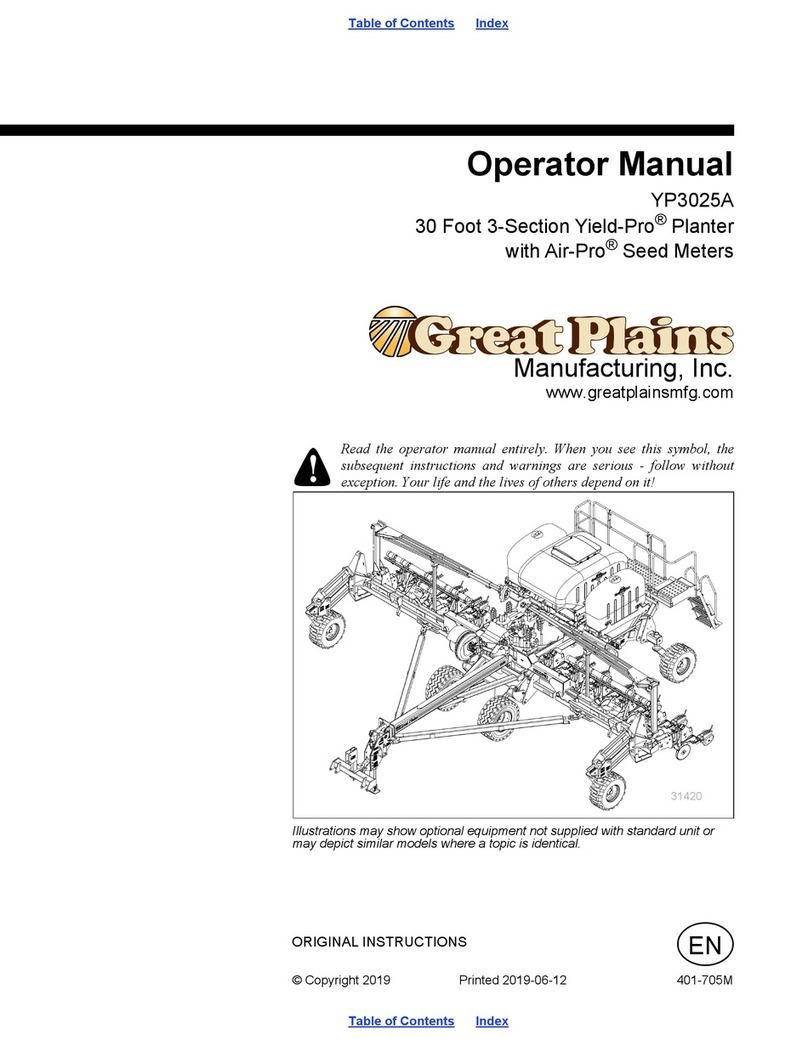

YP3025A Cover Index iii

2020-08-07 Cover Index 401-705M

© Copyright 2010, 2011, 2012, 2014, 2015, 2016, 2017, 2019, 2020. All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed

for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products

as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

Trademarks of Great Plains Manufacturing, Inc. include: AccuShot, Max-Chisel, Row-Pro,

Singulator Plus, Short Disk, Swath Command, Terra-Tine, Ultra-Chisel, and X-Press.

Registered Trademarks of Great Plains Manufacturing, Inc. include: Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone,

Nutri-Pro, Seed-Lok, Solid Stand, Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo-Max, Turbo-Till, Ultra-Till, Whirlfilter, and Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

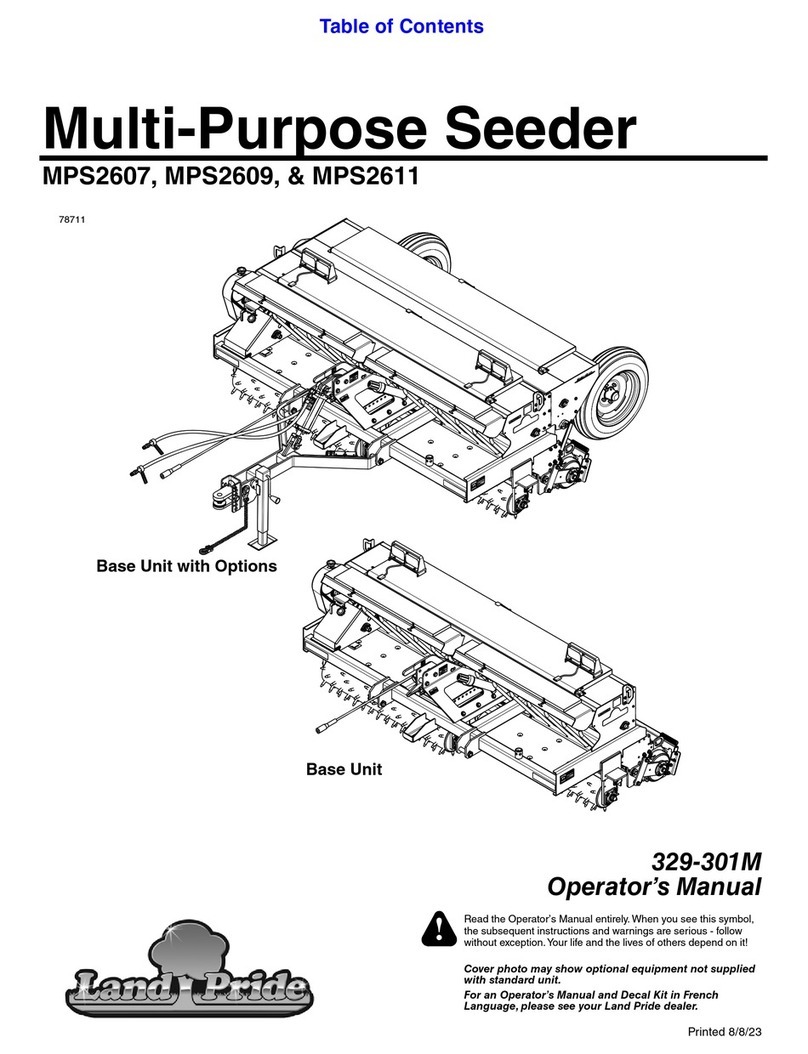

Table of Contents

Important Safety Information.................................................1

Safety Decals ....................................................................6

Introduction...........................................................................13

Description of Unit ...........................................................13

Intended Usage ........................................................13

Models Covered ..............................................................13

Document Family .....................................................13

Using This Manual...........................................................14

Definitions.................................................................14

Owner Assistance............................................................14

Further Assistance...........................................................15

Preparation and Setup .........................................................16

Initial Setup......................................................................16

Post-Delivery/Seasonal Setup.........................................16

Pre-Planting Setup ..........................................................16

Hitching Tractor to Planter...............................................17

Hydraulic Hose Hookup............................................17

If Weight Transfer is Installed...................................17

Electrical Hookup.............................................................19

Hitching with 3-Point.................................................19

Hitching with Hydraulic Tongue (Option)..................20

Raising/Lowering Tongue.........................................20

Parking Stands ................................................................21

Tank Cart Hitching....................................................21

Making Fertilizer Connections ..................................22

Heights and Leveling .......................................................23

Set Tongue Height ...................................................23

Row-Pro™ Setup (Option)...............................................24

Marker Setup ...................................................................24

Lock Up Fertilizer Drive ...................................................25

AccuShot System (Option) ..............................................25

Operating Instructions .........................................................26

Pre-Start Checklist...........................................................26

Fold/Unfold Lock Overview..............................................26

Unfolding the YP3025A Planter.......................................27

Raising/Lowering Planter.................................................29

Raising Planter .........................................................30

Lowering Planter ......................................................30

Lift Cylinder Lock-Up ................................................31

Re-Phasing Lift System............................................31

Local Float on Hydraulic Tongue..............................31

Folding the YP3025A Planter ..........................................32

Re-phasing Fold System ..........................................34

Transporting the Planter ..................................................34

Typical YP3025A Planter Weights ...........................36

Transport Checklist ..................................................37

Loading Materials ............................................................37

Walkboard and Ladder.............................................37

Auxiliary Hydraulics..................................................38

82 Bu. Hopper Operation .........................................40

150 Bu. Hopper Operation .......................................41

Changing the Seed Box or Hopper ..........................42

Air System Operation ......................................................44

Air System Overview................................................45

Fan Circuit Operation ..............................................46

Fan General Operating Information ........................47

Recommended Fan Speeds ................................... 47

Y-Tubes....................................................................48

Airbox Operation ......................................................48

Air-Pro® Meter Operation ................................................49

Meter Operation .......................................................49

Weight Transfer Operation (Option) ................................50

Clutch Operation .............................................................50

Clutch Overrides ......................................................51

Electric Clutch Lock-Up............................................51

Fertilizer Tanks (Option)...........................................52

Trailer Operations............................................................53

CFM Pump Switch ...................................................53

Field Set-Up Checklists ...................................................54

Caster Locks - Field Operations...............................55

Field Operation................................................................56

Marker Unfolding .............................................................57

Marker Unfold (one side)..........................................57

Row Marker Operation .............................................58

Folding the Markers .................................................58

Unusual Marker Operations .....................................58

Monitor Operation............................................................58

Planting ...........................................................................59

Checking Planting Rate...................................................59

Short-Term Parking .........................................................59

Long-Term Storage .........................................................60

Storage: Fertilizer Option .........................................60

Adjustments..........................................................................61

Setting Material Rates .....................................................62

Planting Rate............................................................62

Fertilizer Rate...........................................................62

Marker Adjustments ........................................................63

Marker Disk Adjustment ...........................................63

Fan and Adjustment ........................................................64

Furrow Check: 65