HEADQUARTERS:AndersonPowerProducts®,13PrattsJunctionRoad,Sterling,MA01564-2305 USA

T:978-422-3600 F:978-422-3700www.andersonpower.com HEADQUARTERS:AndersonPowerProducts®,13PrattsJunctionRoad,Sterling,MA01564-2305 USA

T:978-422-3600 F:978-422-3700www.andersonpower.com

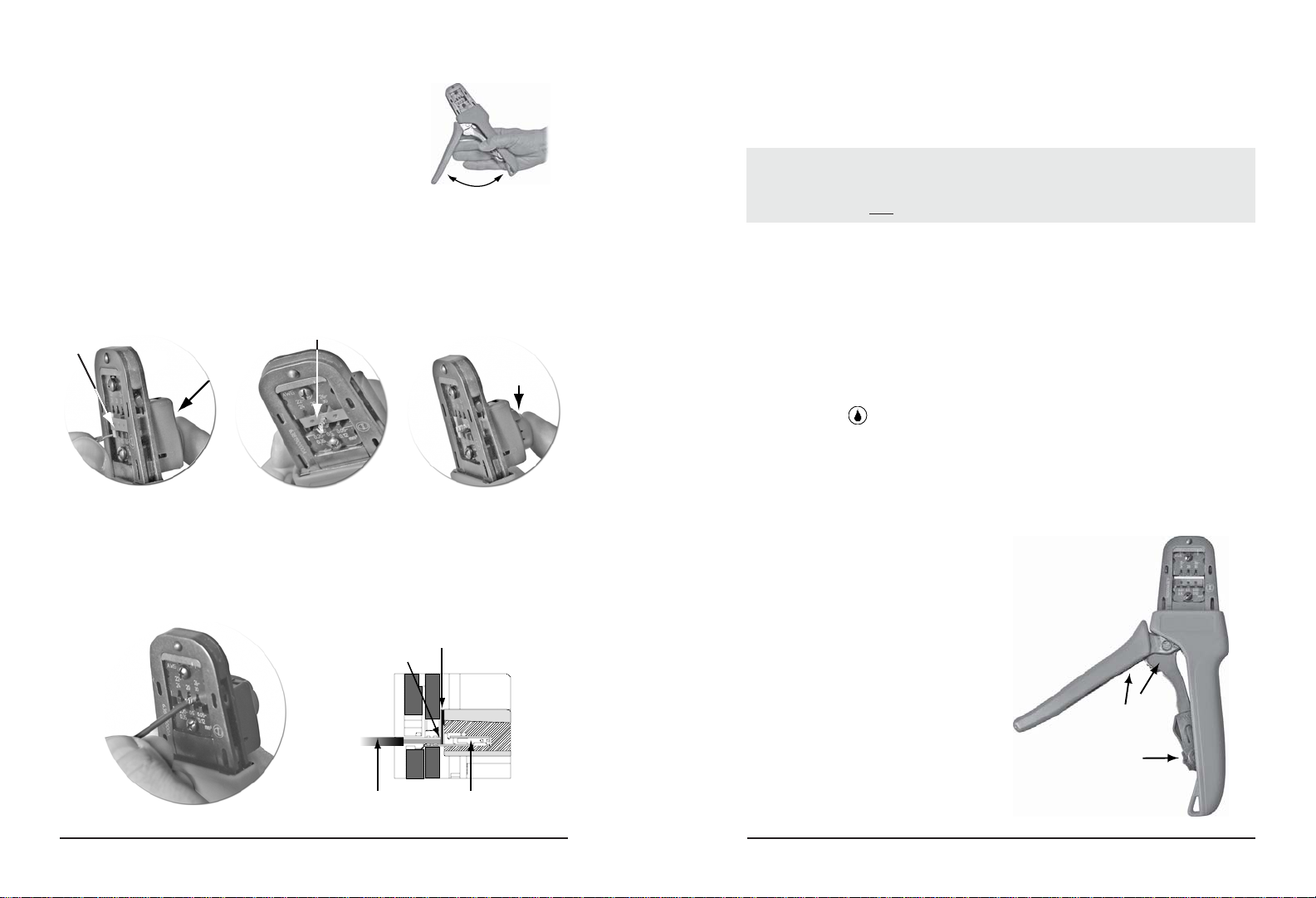

Figure 5 Figure 5a

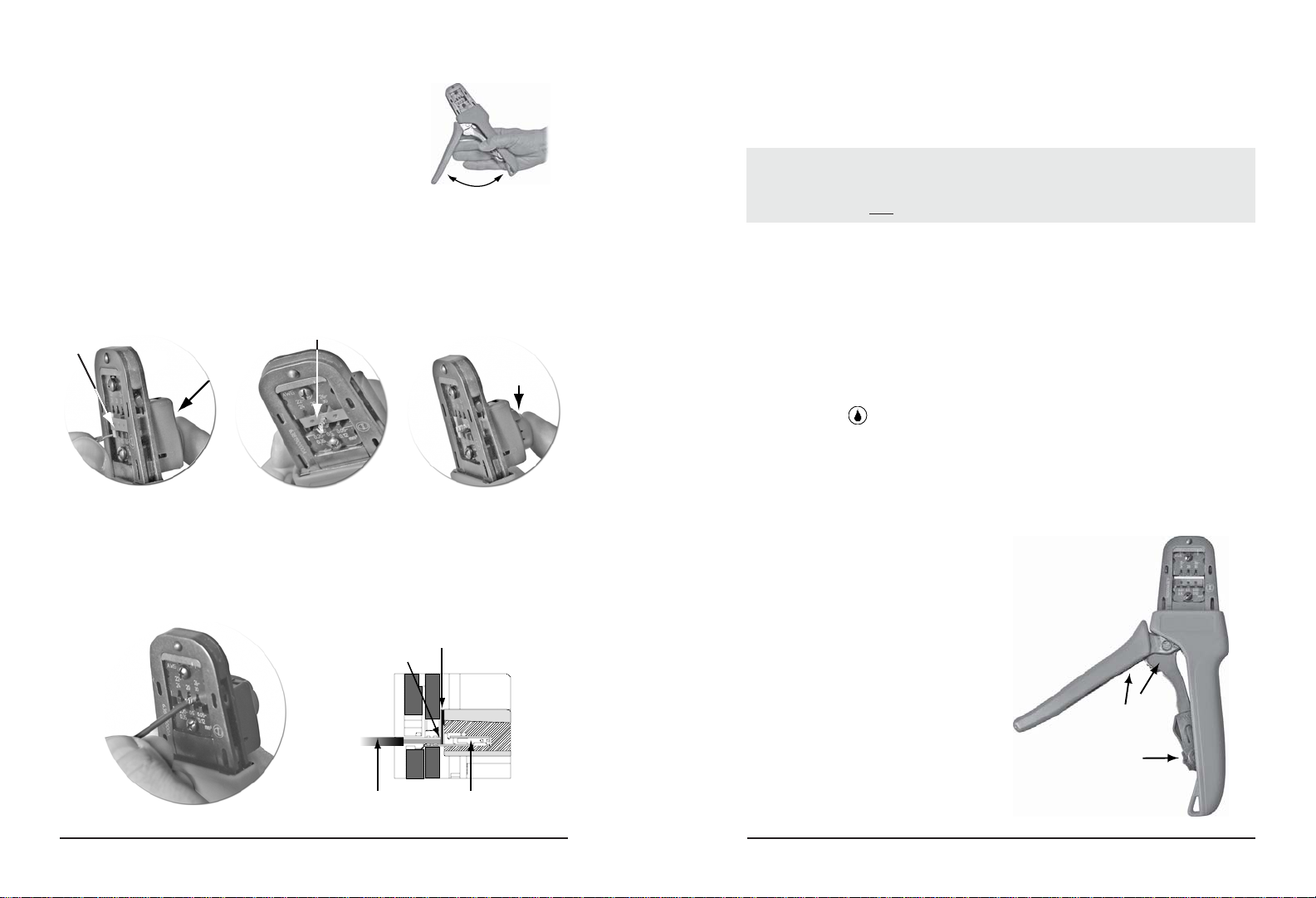

OPERATION

Open the tool by squeezing the handles together.At the end of the

closing stroke, the ratchet mechanism will release the handles and

the hand tool will spring open. (See Figure 1)

Crimping Terminals

1. Select the desired terminal listed in the preceding charts.

2. HandlesofthetoolsmustbeinthefullyopenpositionasinFigure

1. With the locator attached, push the locator button on the back

of the hand tool to bring the locator forward through the tooling.

(See Figure 2)

3. While holding the locator button in, load the terminal into the

proper nest opening in the locator based on the wire gauge or

terminal type markings on the hand tooling. (See Figure 3)

7. Crimptheterminalbysqueezingthetoolhandlesuntiltheratchetmechanismcyclehasbeencompleted.

Release the handles to open the jaws.

8. Remove the crimped terminal from the terminal locator by pulling on the wire.

9. Visually inspect the crimped terminal for proper crimp location.

RatchetingHandleSqueeze

handlestogetherandrelease

handlewillspringopen

Figure 1

4. Release the locator button, allowing the locator to return to the crimping position. (See Figure 4)

5. Close the tool handle until the first ratchet position engages.

6. Insert the properly stripped wire through the terminal and against the wire stop. (See Figure 5 & 5a)

Figure 2 Figure 3 Figure 4

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following

maintenance steps:

1. Remove dust, moisture, and other contaminants with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

3. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high

quality machine oil (See Figure 6).Do notoil excessively. Lightoil(suchas30weightautomotive

oil) used at the oil points, every 5,000 crimps or 3 months, will significantly enhance the tool life.

4. Wipeexcess oilfrom handtool, particularly from crimping area.Oil transferredfrom thecrimping area

onto certain terminations may affect the electrical characteristics of an application.

5. When tool is not in use, keep the handles closed to prevent objects from becoming lodged in the

crimping dies, and store the tool in a clean, dry area.

Wirestop is part

ofthelocator

Wireagainstthe

wirestop

Wire Terminal

Note: Acrimp height chart is provided with this manual as Reference Only. Due to the wide range of

wires, strands, insulation diameters, and durometers available, actual crimp height measurements

may vary slightly.An occasional, destructive, pull force test should be performed to check hand tool

crimp. Pull Force value Must exceed the minimum pull force specifications listed.

LubricationPoints

(usea light oil every 3

monthsor5,000crimps)

Figure 6

Releaselocator

buttonwithcontact

inserted

Terminalloadedintolocator

LocatorPushed

thrutool Locatorbutton

pushedin