Continental Refrigerator PC125-RCD User manual

Other Continental Refrigerator Crimping Tools manuals

Continental Refrigerator

Continental Refrigerator PC150 User manual

Continental Refrigerator

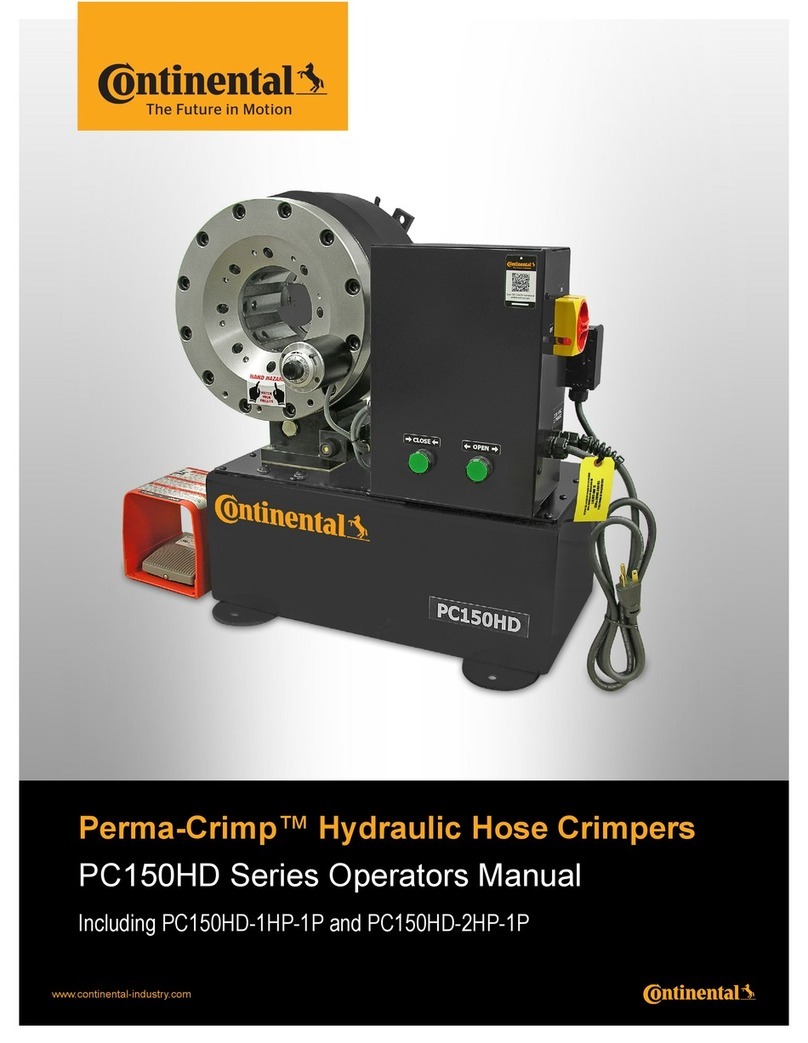

Continental Refrigerator PC150HD User manual

Continental Refrigerator

Continental Refrigerator PC150HD User manual

Continental Refrigerator

Continental Refrigerator Perma-Crimp PC125 User manual

Continental Refrigerator

Continental Refrigerator PC440 User manual

Continental Refrigerator

Continental Refrigerator PC150 User manual

Continental Refrigerator

Continental Refrigerator PC150H Series User manual

Popular Crimping Tools manuals by other brands

Tyco Electronics

Tyco Electronics 90035-3 instruction sheet

Emerson

Emerson Klauke ES 20RMCCFB manual

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet