molex AT FIFG User manual

Other molex Crimping Tools manuals

molex

molex 78172 Series User manual

molex

molex CR5904 User manual

molex

molex 207128 Series User manual

molex

molex 64001-1000 User manual

molex

molex 207129 Series User manual

molex

molex AT-200 Manual

molex

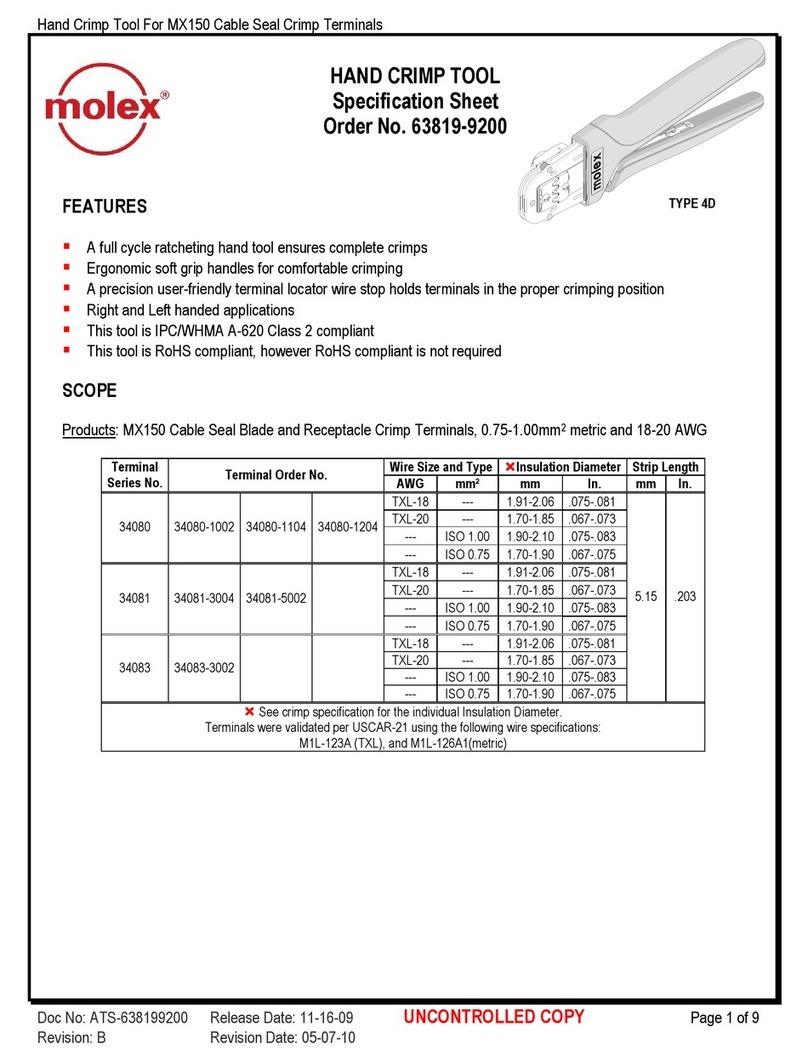

molex 63819-9200 User manual

molex

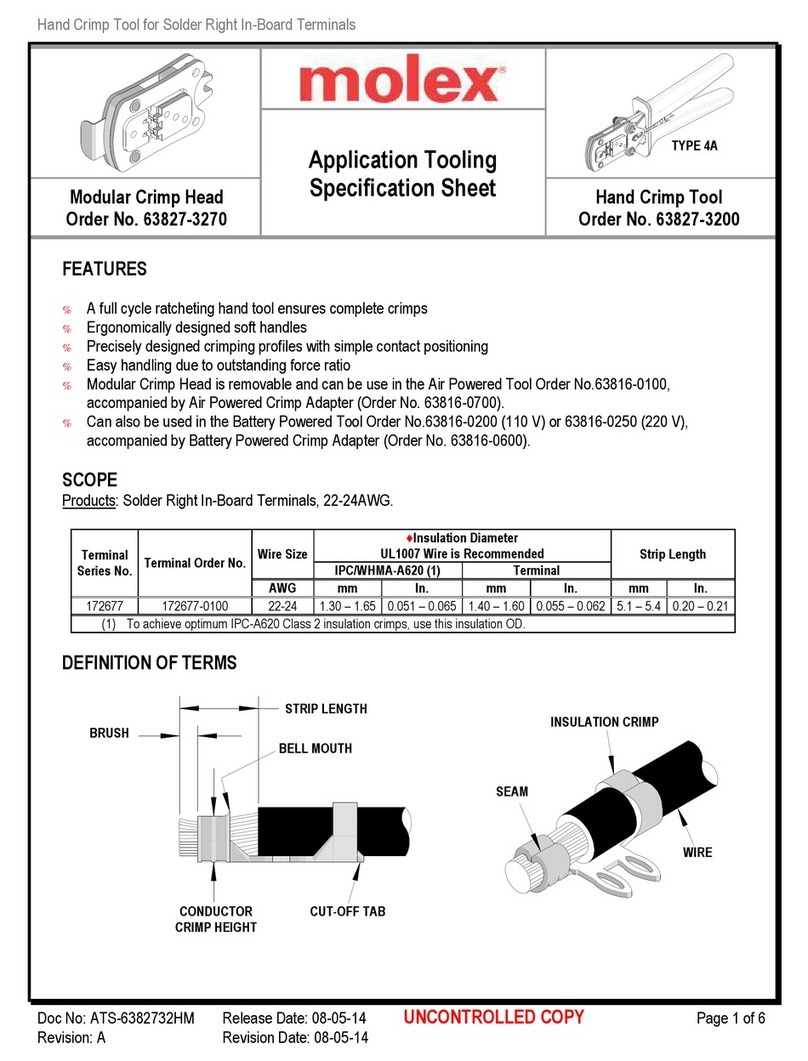

molex 63827-3200 User manual

molex

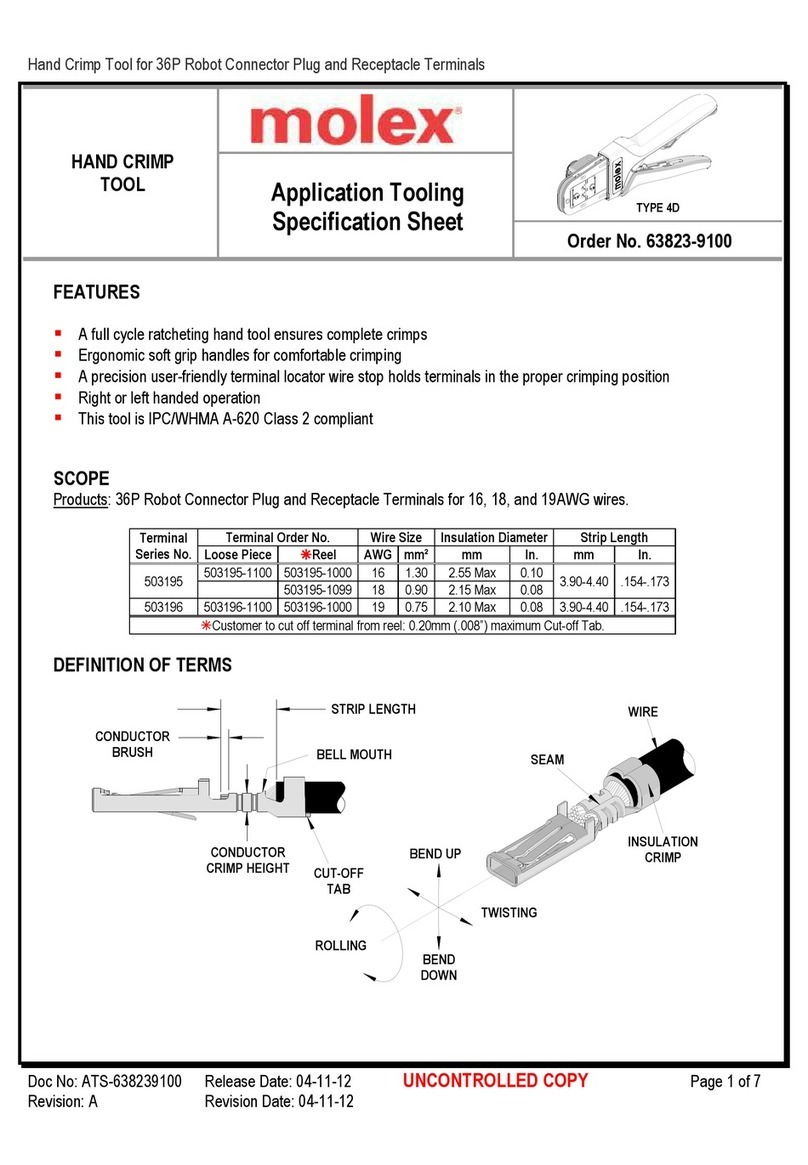

molex 63823-9100 User manual

molex

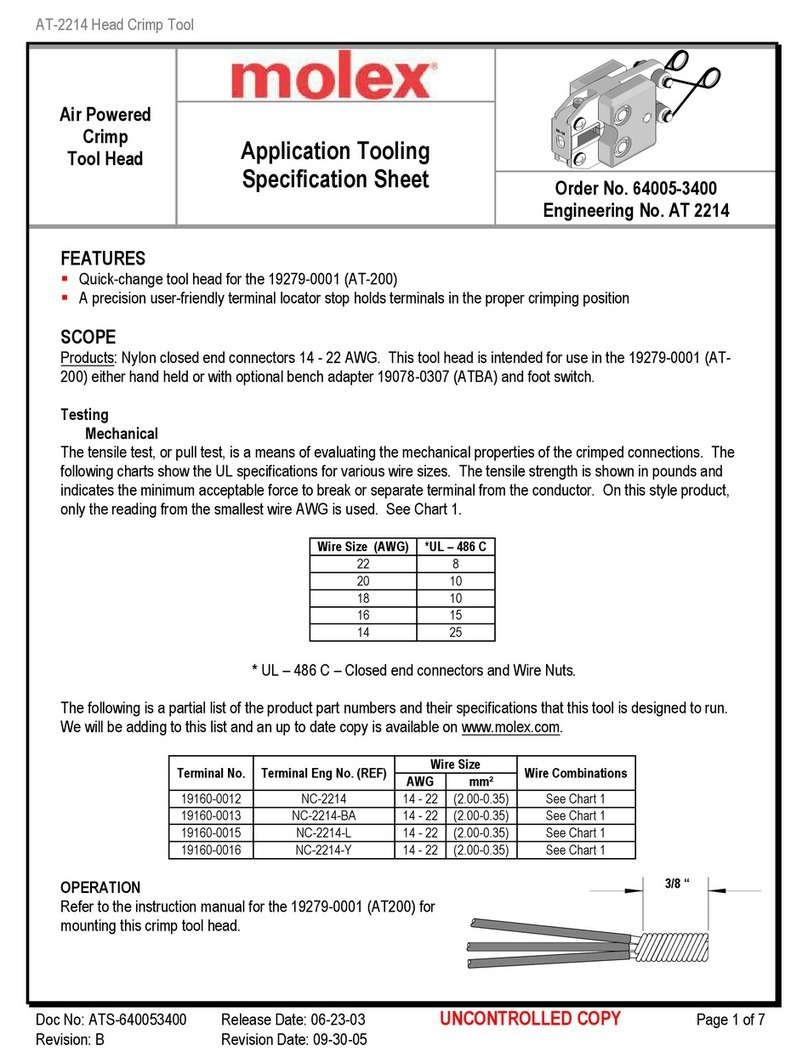

molex 64005-3400 User manual

molex

molex 63823-8000 User manual

molex

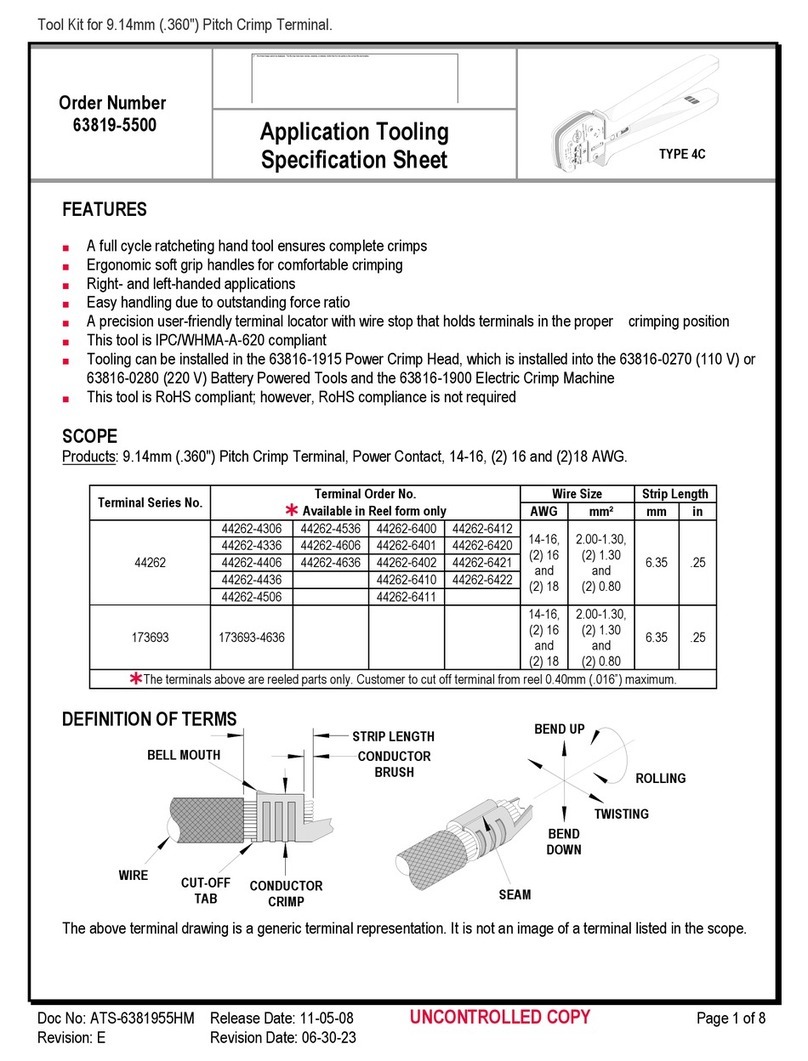

molex 44262-4306 User manual

molex

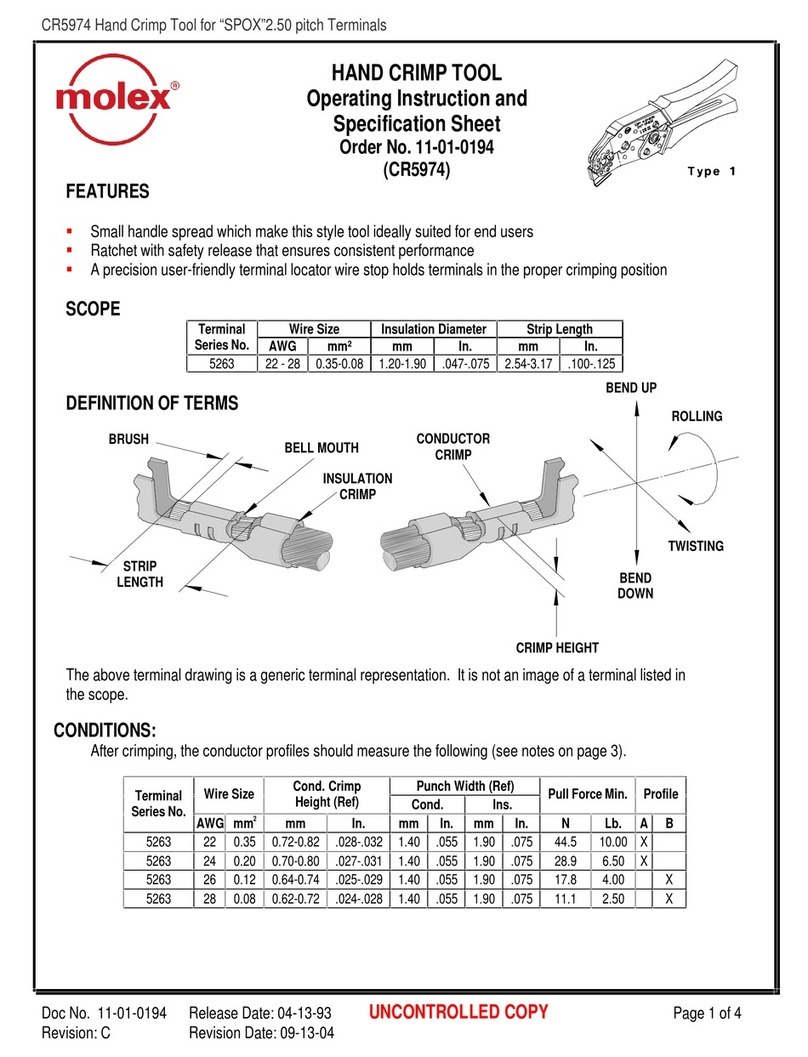

molex CR5974 User manual

molex

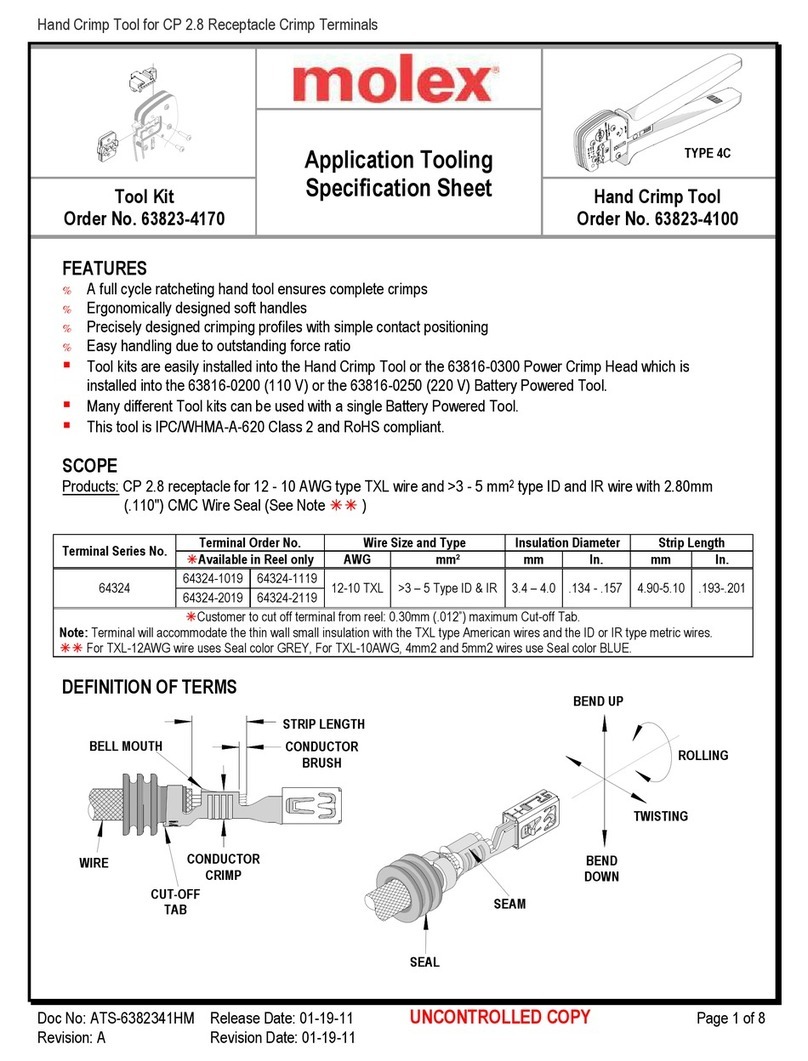

molex 63823-4100 User manual

molex

molex AT 1992 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63827-1600 User manual

molex

molex 63823-0400 User guide

molex

molex 63811-7100 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet