THANK YOU FOR PURCHASING AN APP PUMP.

Takethetimetoreadtheinstructionscarefullybeforeusingthisappliance.Westrongly

recommendthatyoukeepthisinstructionmanualinasafeplaceforfuturereference

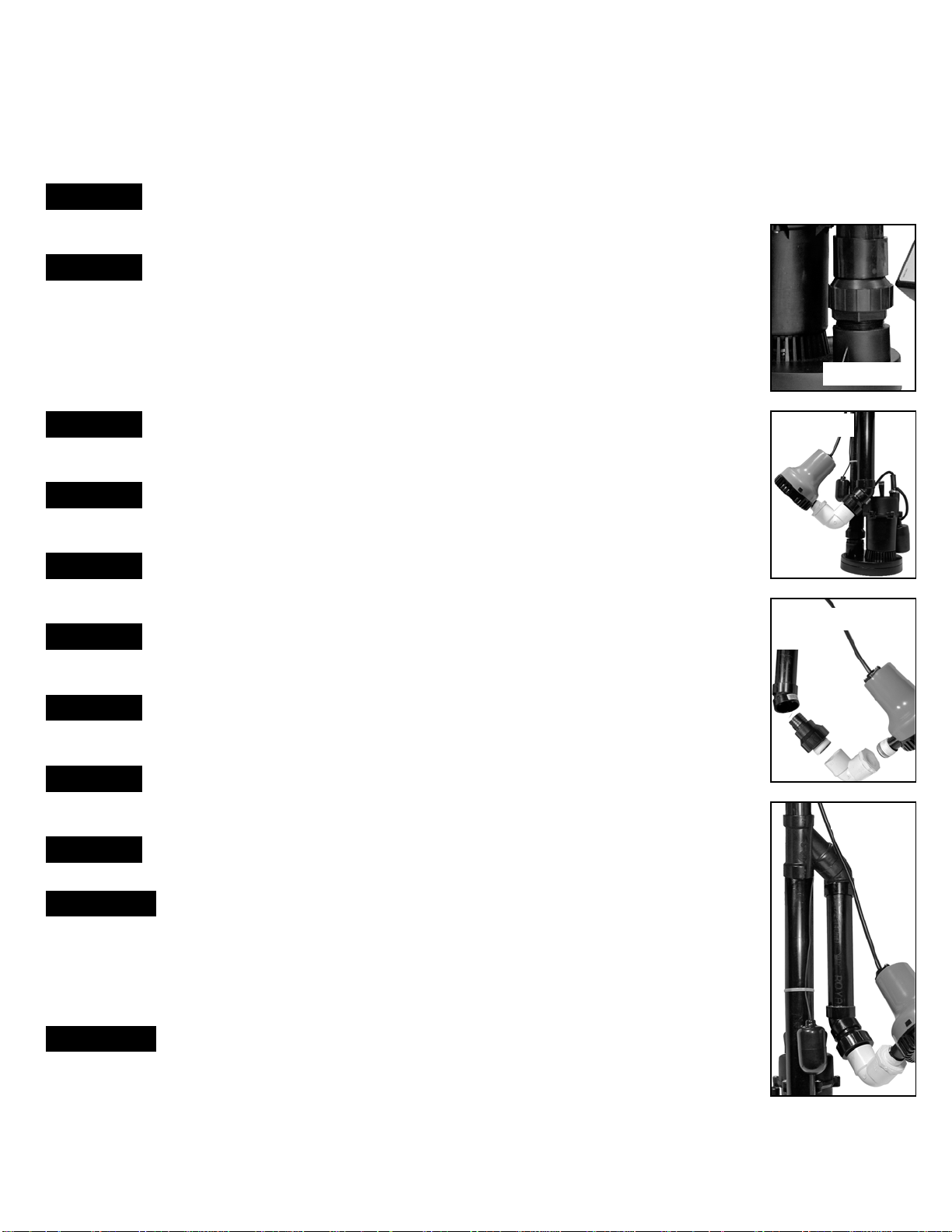

General Materials needed for Battery back-up sump pump

PUMP INSTALLATION

- Teflon tape.

- Desired length of PVC or ABS pipe and fittings, to link up back-up pump discharge to existing discharge

pipe.

TOOLS

- Screwdrivers, hacksaw to cut pipe, knife to assist in pipe cutting, round file to smooth pipe ends, pipe

wrench, and adjustable wrench to tighten fittings, propane torch and welding material.

BATTERY

- Use only a new fully charged 12 Volt deep cycle marine battery. Electrolyte level must be checked and

maintenance must be done in accordance with manufacturer’s guideline.

- Battery sizes that will fit into the battery box are 24C, 24VCM, 27C, 27CM, and 27F.

- Battery recharge time will be different at each installation. Under normal conditions it will take two to four

days to bring a deep cycle battery back to full charge after it has been discharged. If electrical power to the

house is lost more than once a week, consider keeping a spare, fully-charged battery to replace an

exhausted battery for the standby sump pump.

After each start, the pump will run for 5 to 30 seconds after the float return to it’s original position.

READ THESE RULES AND INSTRUCTIONS CAREFULLY.

1. Before installing or servicing your pump:BE CERTAIN pump power source is disconnected.

2. Plumbing and electrical wiring must adhere to state and local codes. Check appropriate community agencies,

or contact local electrical and pump professionals.

3. Keep the battery box in a cool, dry, well ventilated area away from sparks or flames. Battery exposure may

result in an explosion or fire.

4. Beware of battery acid; it is very corrosive.

5. BATTERY MAINTENANCE (every 3 months on batteries with removable top caps): Unplug battery

charger. Measure the specific gravity of the electrolyte in each cell with a hydrometer. If the specific gravity falls

below 1.225 in any one cell or varies more than .050 between all the cells, replace the battery. Check the

electrolyte level and fill as required. Check battery terminals and clamps for tightness and corrosion; service as

required. Plug battery charger back in.

6. Replace the battery if the back-up pump operates for an extended period and severely discharges the battery.

We recommend battery replacement every 3 years regardless of system use.

7. When servicing the pump, use care:

♦Disconnect power at main electrical service box by turning circuit breaker off or by removing the fuse.

♦Disconnect battery charger from wall outlet.

♦DO NOT lift pump by the power cord.

8. This system is intended for back-up use during power outage, not as a primary pump. DO NOT RUN DRY.