Chapter 1 Basics of Firetube Operation

1-2 750-184

The general information in this manual applies directly to

Cleaver-Brooks Model CB Boilers in sizes ranging from 125

through 200 boiler horsepower for the following fuels:

Series 100 Light Oil (No. 2)

Series 200 Light Oil (No. 2) Or Gas

Series 400 Heavy Oil (No. 6) Or Gas

Series 600 Heavy Oil (No. 6) Only

Series 700 Gas Only

Note: Although the Series 400 or 600 burner

is designed and designated to burn No. 6

oil, the burner will handle grades 4 and 5

equally well, with some possible

adjustments. While the manual contains

pertinent information on No. 6 fuel oil, all

references to No. 6 fuel should be

considered applicable to all grades of heavy

oil.

The LE Option, available on Cleaver-Brooks Firetube

Boilers, reduces Nitrogen Oxide (NOx) emissions, a major

precursor to ozone pollution (smog). Carbon Monoxide (CO)

emissions also tend to be lower, due to increased turbulence

caused by the addition of the flue gases into the combustion

air stream, thereby improving combustion.

Note: For information on IFGR when firing

heavy oil, review the Operation and

Maintenance manual for Heavy Oil Isolation

750-171

The LE Option is used on Cleaver-Brooks Model CB Firetube

boilers firing either natural gas and/or light oil, and is

compatible with both hot water and steam systems.

The IFGR system mixes a portion of the relatively cool flue

gas from the exit of the fourth-pass tubes with the incoming

combustion air to reduce the furnace flame temperature,

thereby reducing NOx emissions. In this approach, the

combustion air fan handles both the combustion air and the

recirculated flue gases. Accordingly, this method is called

Induced Flue Gas Recirculation (IFGR), because the flue gas

is “induced” into the fan inlet.

The LE Option, with its various levels of IFGR systems, can

affect the selection of the combustion air fan, motor, burner,

and other components. Several different system

configurations are available, depending on the requirements

for NOx emissions and the fuels used. All systems use

similar primary components, but may have different linkage

controls, IFGR damper, fan, and motor sizes.

Always order genuine Cleaver-Brooks parts from your local

Cleaver-Brooks authorized representative.

The boiler and related equipment installation are to be in

compliance with the standards of the National Board of Fire

Underwriters. Installation should also conform to state and

local codes governing such equipment. Prior to installation,

the proper authorities having jurisdiction are to be consulted,

permits obtained, etc. All boilers in the above series comply,

when equipped with optional equipment, to Industrial Risk

Insurers (IRI), Factory Mutual (FM), or other insuring

underwriters requirements.

B.THE BOILER

The Model CB boiler is a packaged firetube boiler of welded

steel construction and consists of a pressure vessel, burner,

burner controls, forced draft fan, damper, air pump,

refractory, and appropriate boiler trim.

The horsepower rating of the boiler is indicated by the

numbers following the fuel series. Thus, CB700-200

indicates a gas-fired 200 hp boiler.

The firetube construction provides some characteristics that

differentiate it from other boiler types. Because of its vessel

size, the firetube contains a large amount of water, allowing

it to respond to load changes with minimum variation in

steam pressure.

Firetube boilers are rated in boiler horsepower (BHP), which

should not be confused with other horsepower measure-

ments.

Hot water is commonly used in heating applications with the

boiler supplying water to the system at 180

°

F to 220

°

F. The

operating pressure for hot water heating systems usually is

30 psig to 125 psig.

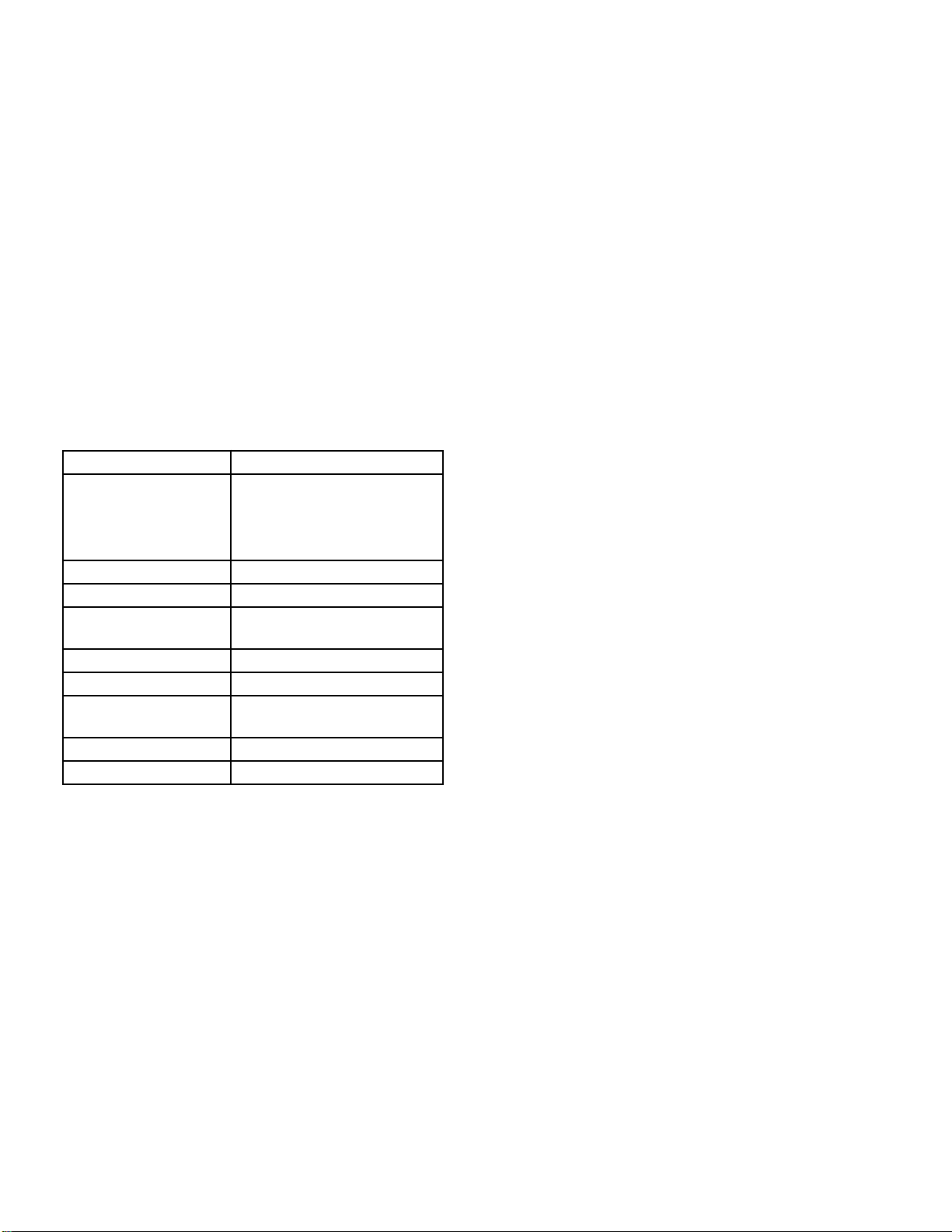

Rated Capacity 125 through 200hp

Operating Pressure Steam15-250 psig, orhigherif

specified

Hot Water 30-250 psig or

higher if specified

Fuel Oil or Gas or Combination

Ignition Automatic

Firing Full Modulation Through

Operating Ranges

Burner (Oil) (Low Pressure) Air Atomizing

Burner (Gas) Non-premix – Orificed Type

Air Damper Rotary Type

(Electrically Modulated)

Steam Trim ASME Code

Water Trim ASME Code