Power Vent Kit

CAUTION

1. Failure to install, maintain and/or operate the

Power Venter in accordance with

manufacturer's instruction may result in

conditions which can produce bodily injury and

property damage.

2. The Power Venter must be installed by a

qualified installer in accordance with all local

codes or, in their absence, in accordance with

the National Fuel Gas Code (ANSI

Z223.1NFPA #54), the National Electric Code

andThe OccupationalHealth and Safety Act

(OSHA)as applicable.

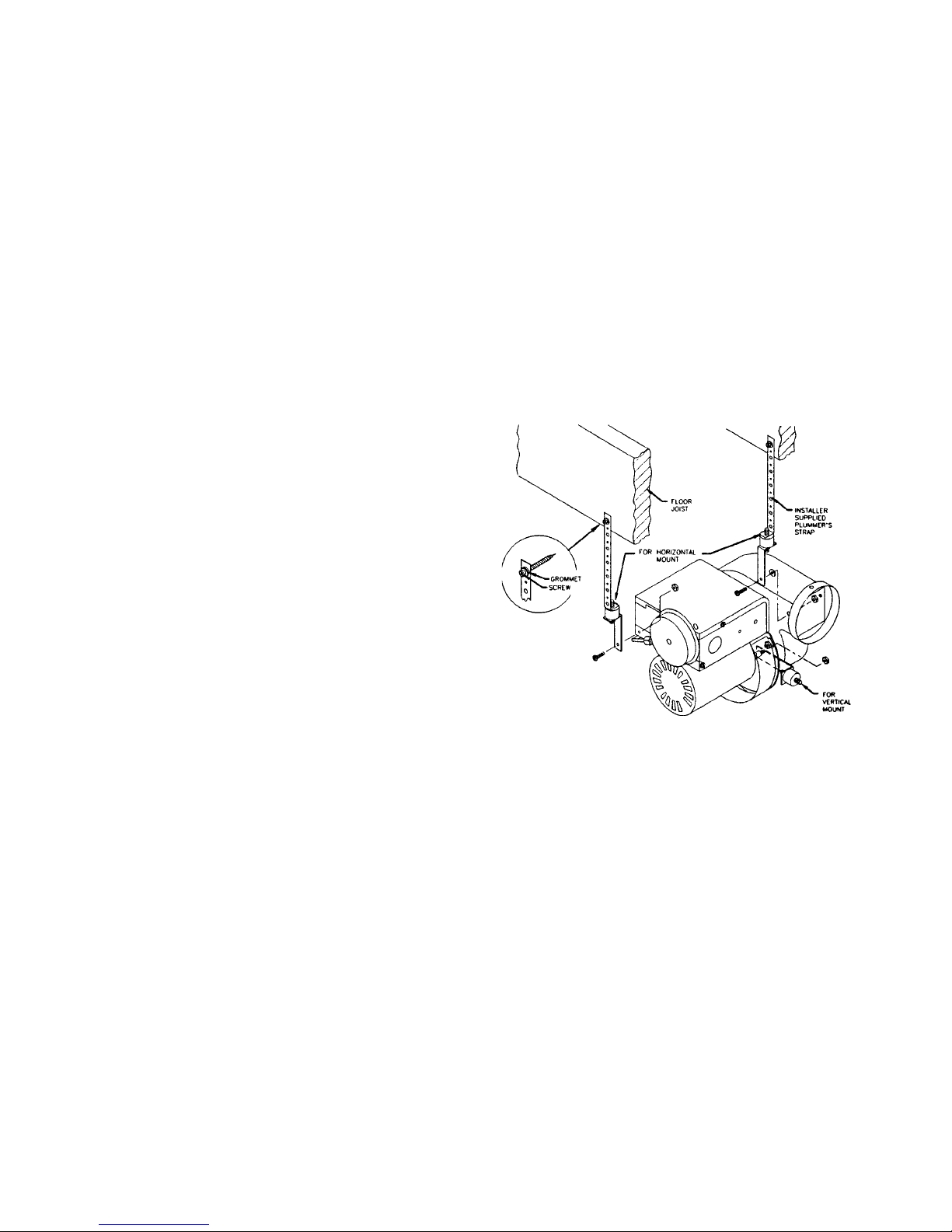

3. The Power venter motor shaft must be

mountedhorizontallyto preventmotorbearing

wear.

4. Disconnect power supply when making wiring

connections or when working around the fan

blade and motor. Failure to do so may result

in severe personal injury and equipment

damage.

5. Make certain the power source is adequate for

the fan motor requirements. Do not add the

power venter to a circuit where the total load

isunknown.

AQ-1 Motor is 200 watts- 1.66 amps @ 120vac

Bosch-Aquastar

1. Followinstallation andoperating instructions

manualsupplied withthe water heater.

2. Beforemounting waterheater to wall, check

itsminimum clearancerequirements.

3. When using an AQ-1 the maximum

horizontaldistance from the water heaterto the

power vent motor is 100 feet. Subtract 10 feet

for each added elbow. Install power vent

motor as close to the termination as

possible to maintain the water heater's

optimal efficiency.

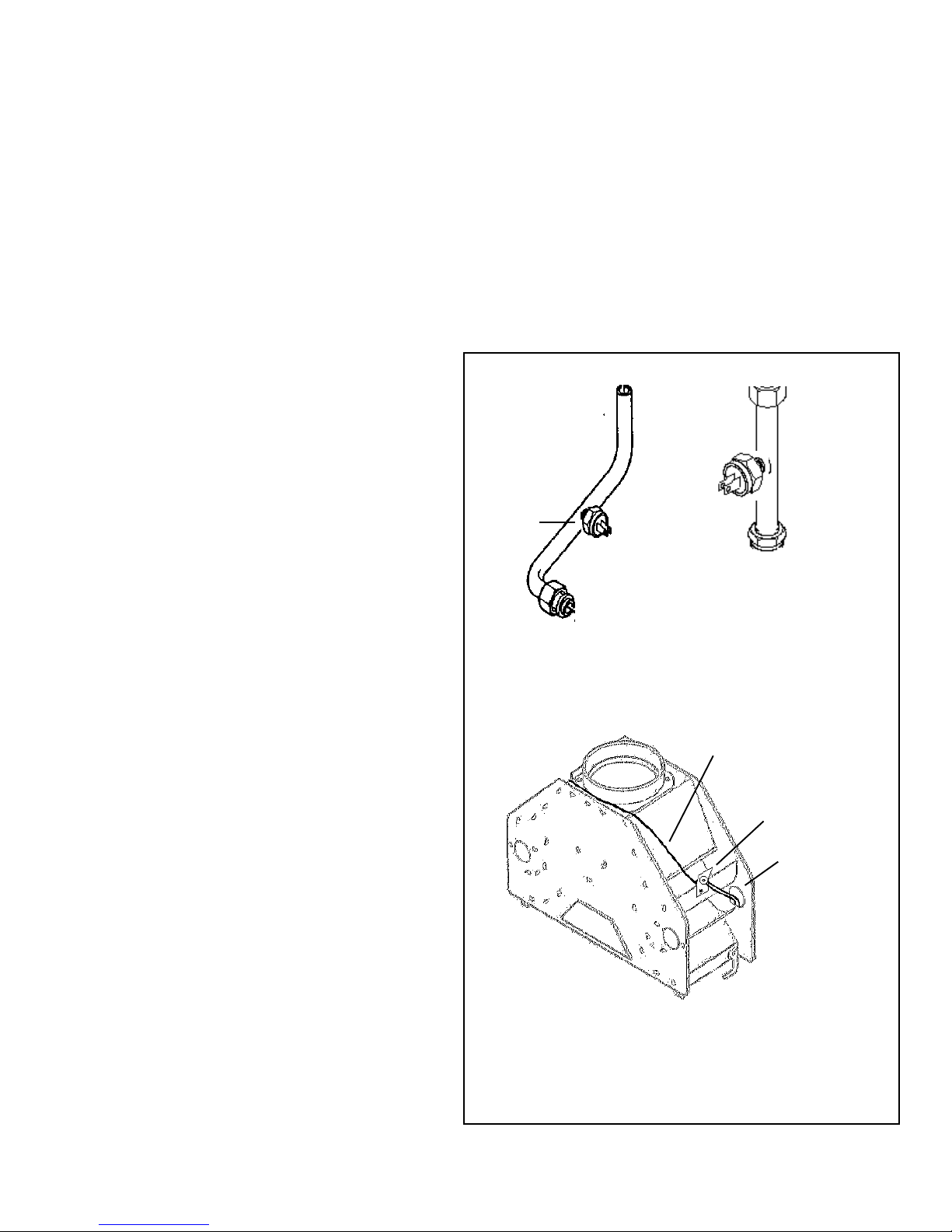

IMPORTANT: FREEZE PREVENTIONTOHEATER

In cold climates the vent hood and power vent mo-

tor will not prevent infiltrating cold air to the water

heater when not in use. Be sure to install the sup-

plied backdraft AQ1FLAPPER accessory within the

vent hood on the outside of the building. If not used,

cold air can enter the vent pipe and freeze the heat-

ers heat exchanger when not in use. Such damage

is not covered under the water heater's warranty.

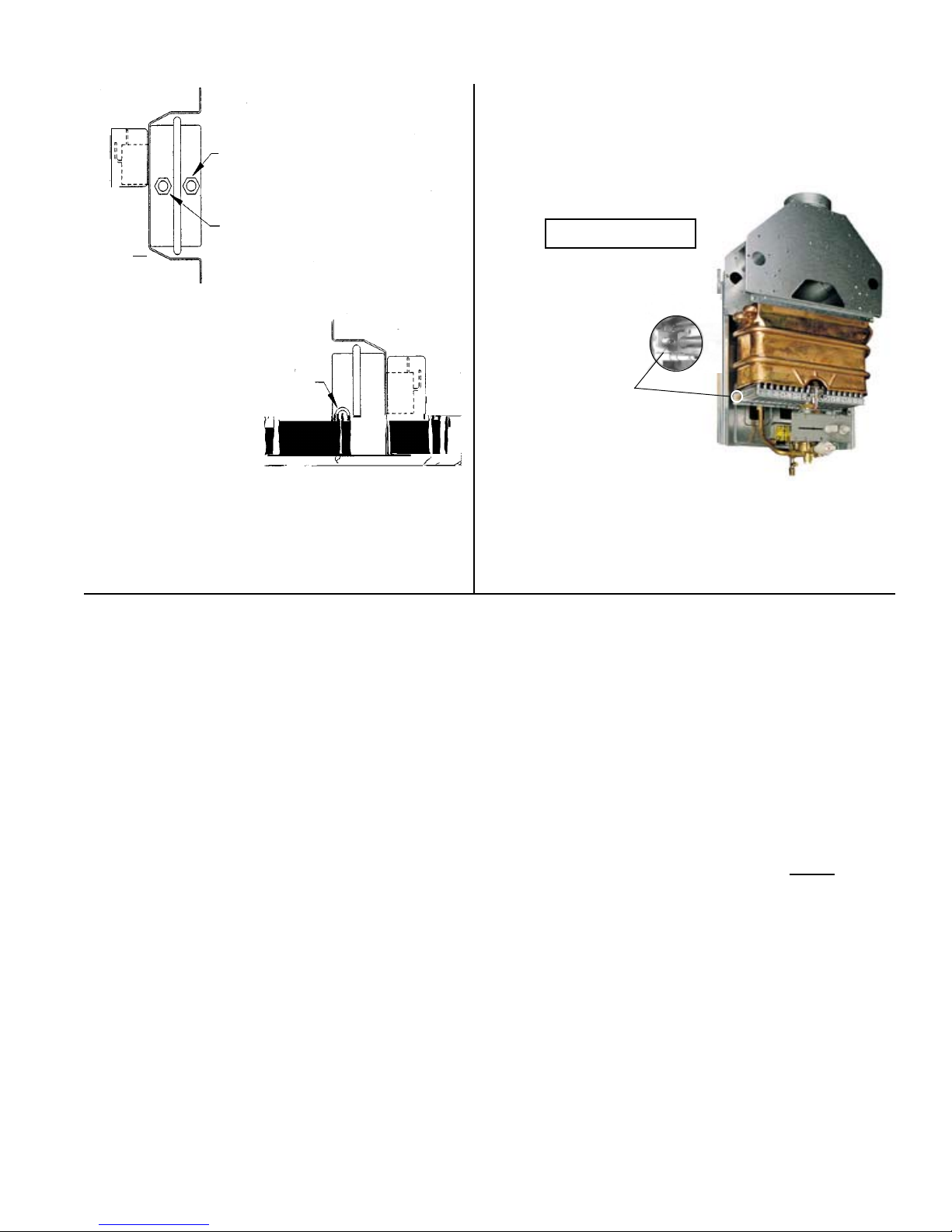

Gas Pressure Switch

Removethe gas pressure switch fromthe bag inthe

carton and the brass 1/4" compression nut fitting which

is meant for theburner manifold tap on the heater, not

the inlet tap on the heater's gas inlet pipe (see p. 3,

FigB). Also remove the four self-tappingscrewsand

the two sections of 1/4" diameter aluminum tubing from

the master carton.

The gas pressure switch must be mounted in such a

waythat the diaphragm is orientedvertically and the

aluminumtubing pieces can easily reach the manifold

pressure test nipple and the burner respectively.

It must not be mounted inside the heater. See

Figure E p.6

When mounting the Gas Pressure Switch: We

recommendmounting thegas pressureswitch vertically

against a wall on the lower left side of the water heater.

See Figure E p.6. Because the cabinet cover is three

sidedwe do not recommend screwingthe gas pressure

switch to the left side of it. Instead, mount the gas

pressure switch vertically against a wall on the lower left

side of the water heater. Installed in this manner all

necessary connections will be within reach and there

willbeminimal interferencewhen servicing.

2

Before beginning installation review

required clearances for Water Heater,

Power Vent Motor and Vent Hood