5

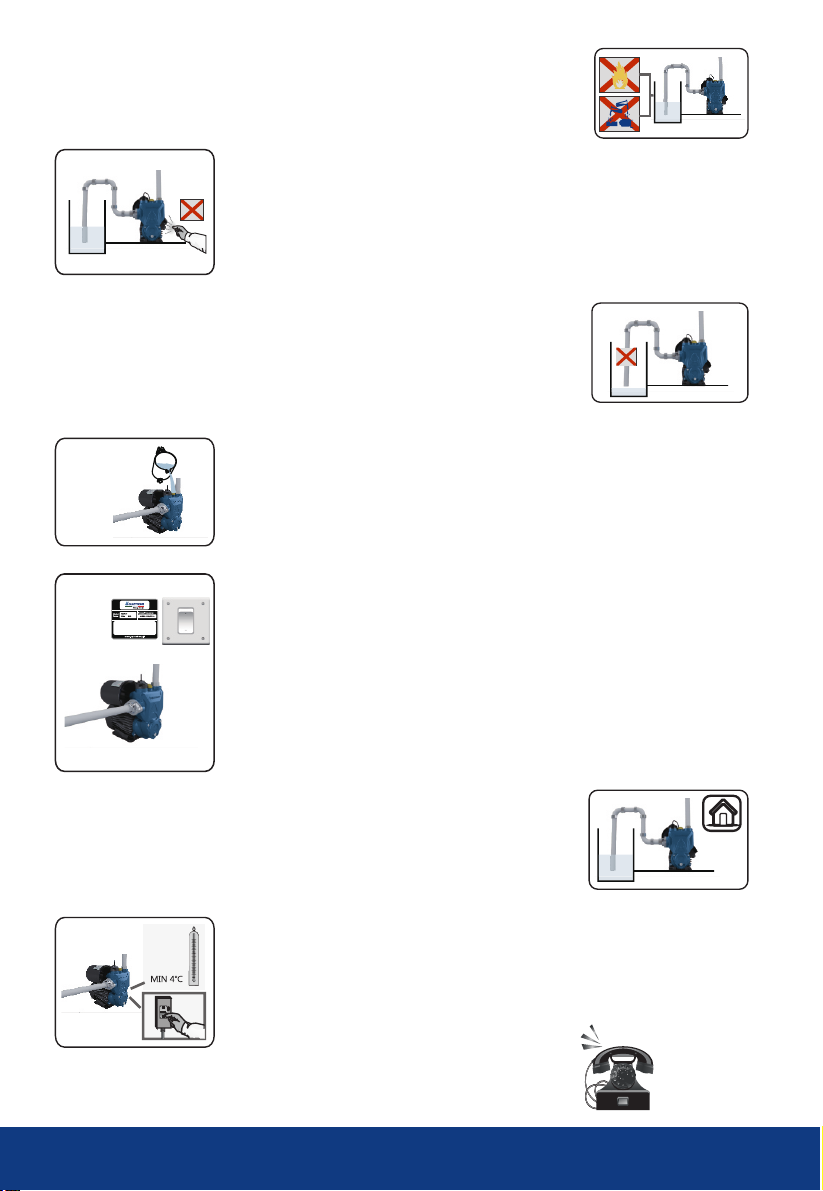

2. Do not use any liquid other than water. When using readily soluble substances

like benzoic acid, flammable materials like gasoline and viscous bottleneck liquids,

it is easy to cause a fire.

4. Avoid operation in a waterless state, for it will shorten the service life of the

pump. When the motor is overheated, it is easy to have malfunctions. Do not

expose the pump to direct light during operation, for it will affect the service life

of the pump. The automatic pumps will enter the water shortage protection

system to protect the pump, so when the user uses the pump for a second time,

he only needs to re-plug the plugto use normally (the tap will open automatically).

3. During operation, it is strictly prohibited to touch the pump. Do not wash,

swim or put livestock in water in the vicinity of the work area in case of accidents.

If abnormalities are found during operation, such as abnormal noise, less water

outlet and intermittent water flow, the power should be cut o ffimmediately

to check and eliminate the fault. When the pump is wet, do not touch the pump

when it is powered on in case of accidents. Avoid splashing water on the pump

and prevent thepump from immersing in water.

5. Before starting, first move the fan blade to check whether the pump can

operate flexibly; then unscrew the water injection plug, fill the pump with clean

water from the water injection hole, then tighten the water injection plug after

the air is exhausted.

Keep the valve almost closed at startup; when there is water discharged, adjust

the valve to have the required flow.

8-1. When the ambient temperature is lower than 4¥, please take antifreeze

measures to prevent the pump from frost crack;

8-2. Keep ventilation

7. If the pump is installed indoors, a drainage system must be arranged near

the pump.

Prevent the pump from immersing in water, for it may cause the motor to burn

out or electric shock. If the pump is not installed as required,which results in the

user抯 property and safety loss, the company will not bear the responsibility.

9. If you have any questions, please refer to the Specification or contact us.

6-1. During installation and maintenance, ensure that the pump won抰 be

accidentally powered on. If it is not used for a long time, close the pipe valves

at the water inlet and outlet, and pay attention to cut o ffthe power first.

6-2. The pumped liquid may be hot and under high pressure. Before moving

and disassembling the pump, the valves must be closed before draining the

pump and the pipe to avoid burns.

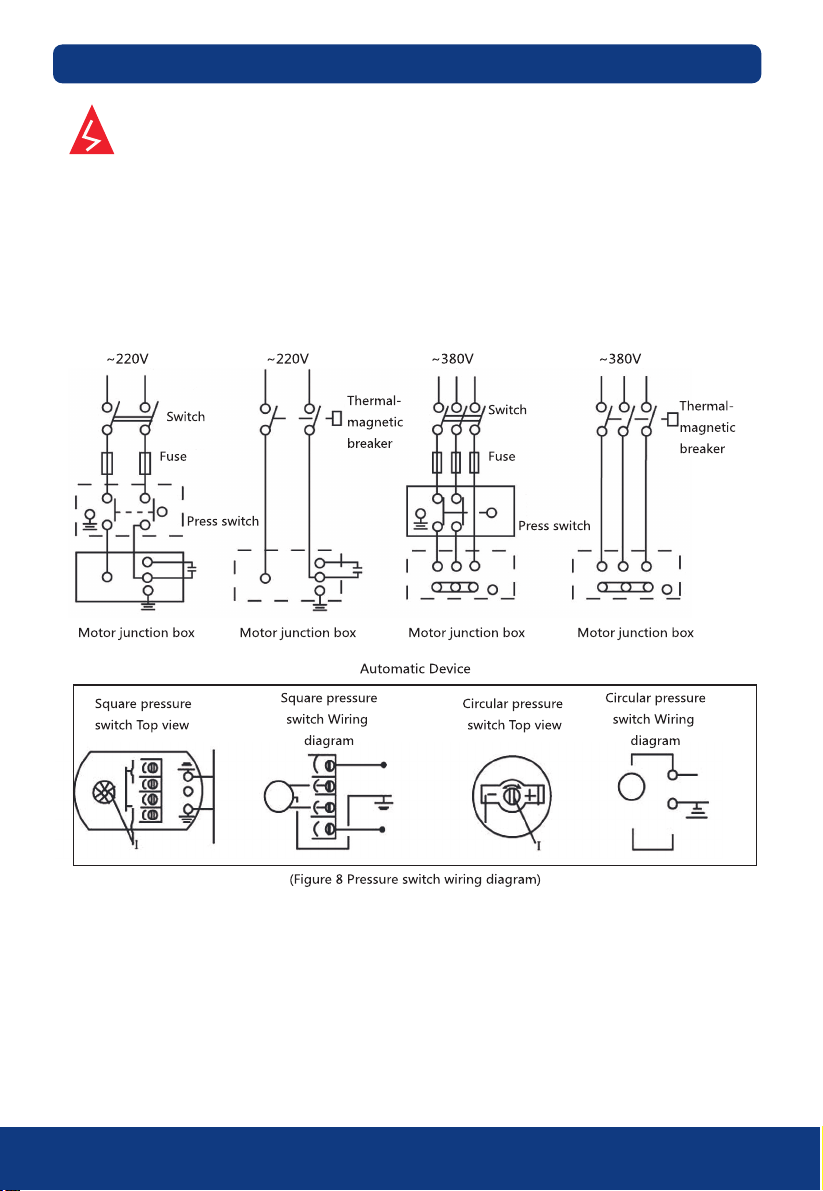

6-3. Supply power according to the voltage indicated on the nameplate. If the

pump is not used for a long time, it should be stored in a dry, ventilated and

cool place at room temperature.

water injection

Max.Head: 25m

Max.Capacity: 1.8m /h

Inlet&Outlet Dia: 25mm

C 10 μF VL 450 V

RPM: 2860r/min

Max.Suction: 8m

l CL B IPX4

Continuous duty

3

Thermally Protected

S.NR: A18090001