Vers 3: March 2016

Foreward

This installation manual is a guide only. All relevent Health and Safety laws and codes of construction

must be adhered too and take precedence over any information in this manual. Installers must

practice good professional practice and are required to understand all National and Local regulations

in respect to the installation of drainage materials.

Contents

1 Product Records for the Homeowner ............................................................................................. 4

1.1 Installer details ........................................................................................................................ 4

1.2 Electricians details................................................................................................................... 4

1.3 Pump details............................................................................................................................ 4

1.4 What happens if the controller alarm activates?.................................................................... 4

2 Intended use.................................................................................................................................... 5

3 Technical Specifications................................................................................................................... 5

4 Holiday Mode (for wastewater pump stations only) ...................................................................... 7

5 Ventilation of the Pump Station...................................................................................................... 7

6 Safety instructions........................................................................................................................... 7

6.1 Maintenance and repair work................................................................................................. 7

6.2 Modifications to the pump station ......................................................................................... 7

6.3 Basic information about safety-conscious work ..................................................................... 7

6.4 Forbidden modes of operation ............................................................................................... 9

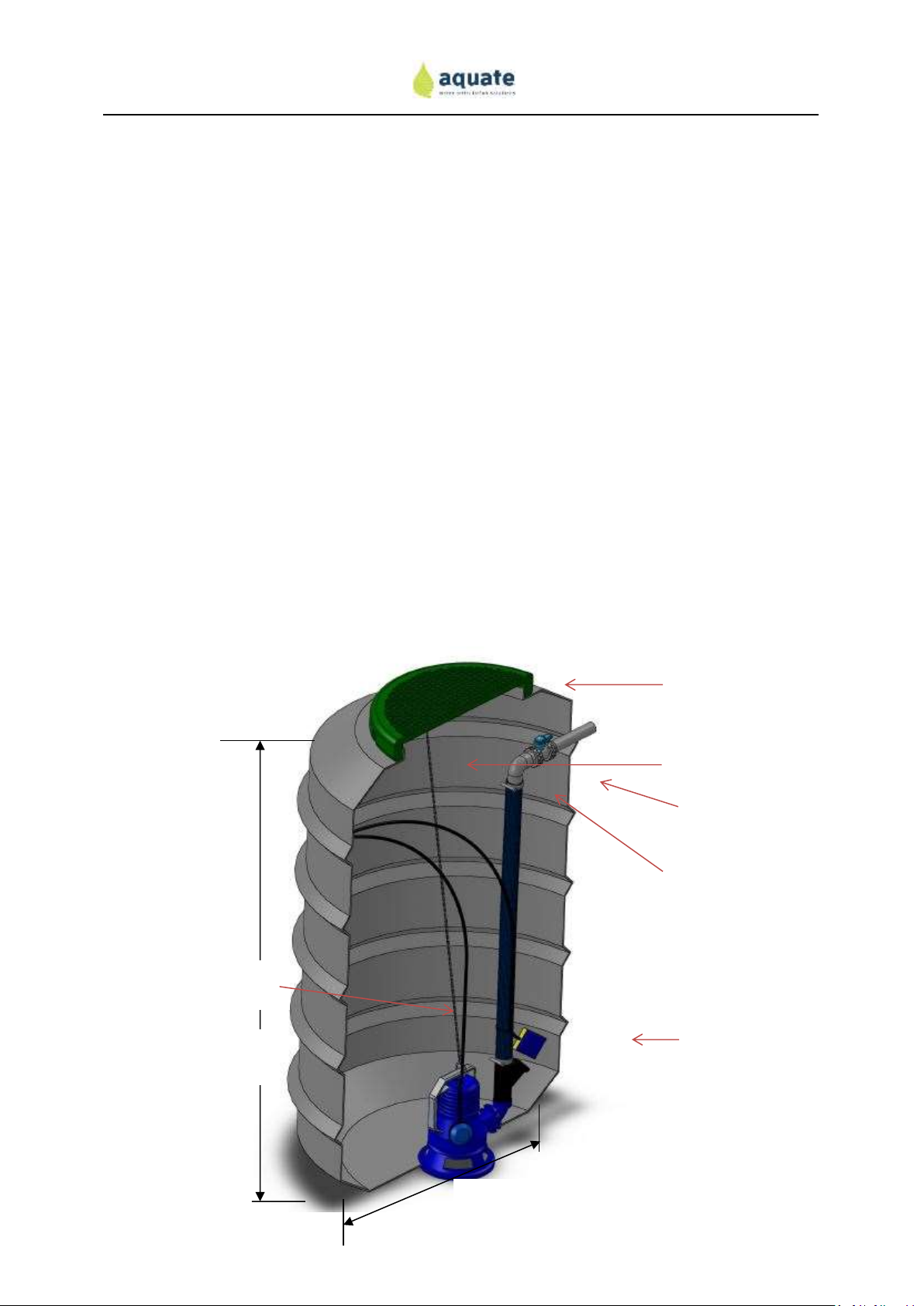

7 Tank Installation .............................................................................................................................. 9

7.1 Transport to Site...................................................................................................................... 9

7.2 Assembly require on-site......................................................................................................... 9

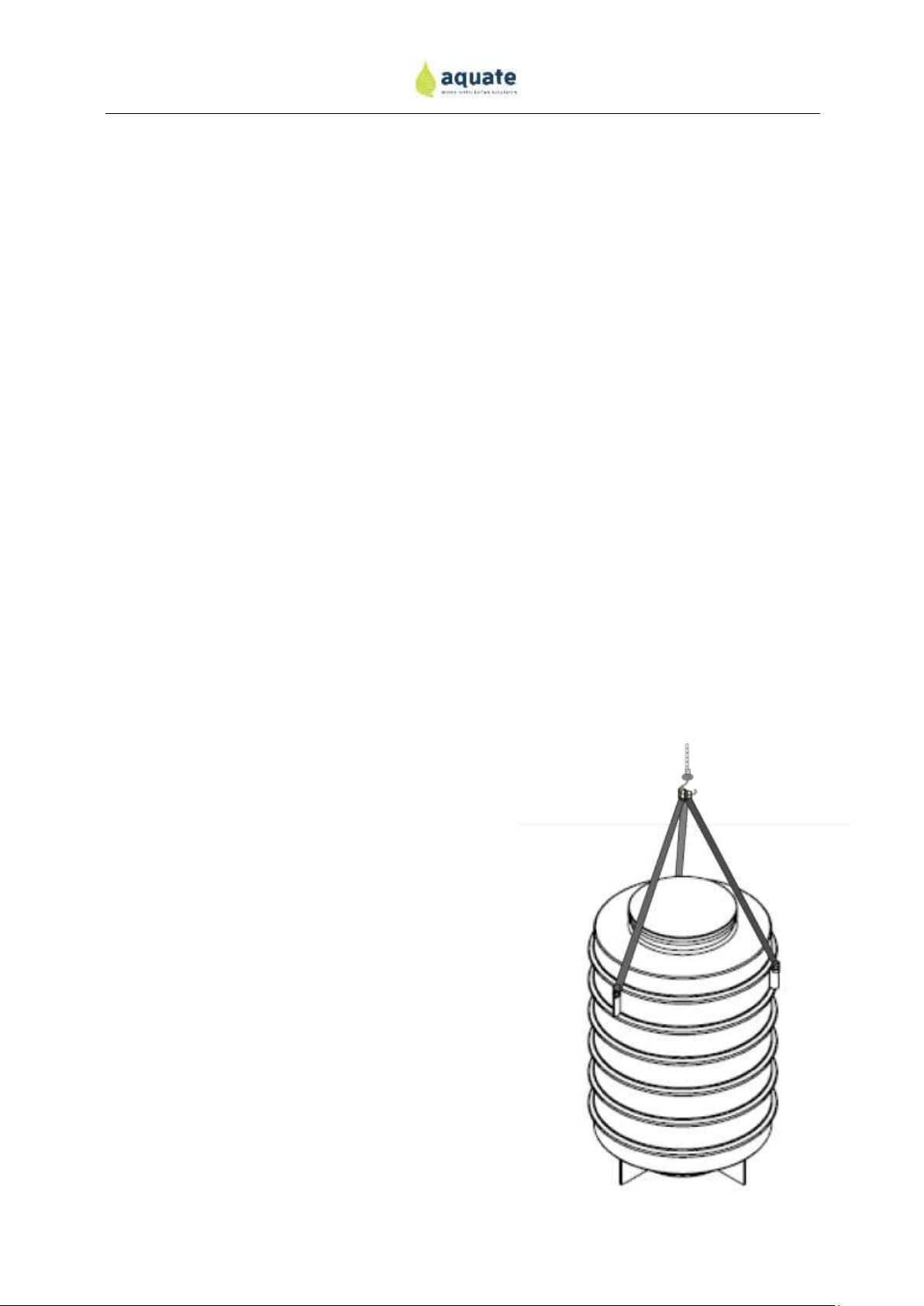

7.3 Lifting the Pump Chamber..................................................................................................... 10

7.4 Excavation and Backfilling ..................................................................................................... 10

7.5 High ground water conditions............................................................................................... 11

7.6 Inlet and Outlet Connections ................................................................................................ 12

7.7 Electrical outlet...................................................................................................................... 13

7.8 Typical Installation................................................................................................................. 13

8 Pump Installation .......................................................................................................................... 14

8.1 Safety..................................................................................................................................... 14

8.2 Vortex or Drainage Pump Models (DG or DR pumps)........................................................... 15

8.3 Grinder Pump Models (GR pumps) ....................................................................................... 18

8.4 Installation Notes .................................................................................................................. 20

8.5 Float Switch ........................................................................................................................... 21

9 Controller Installation.................................................................................................................... 22