8

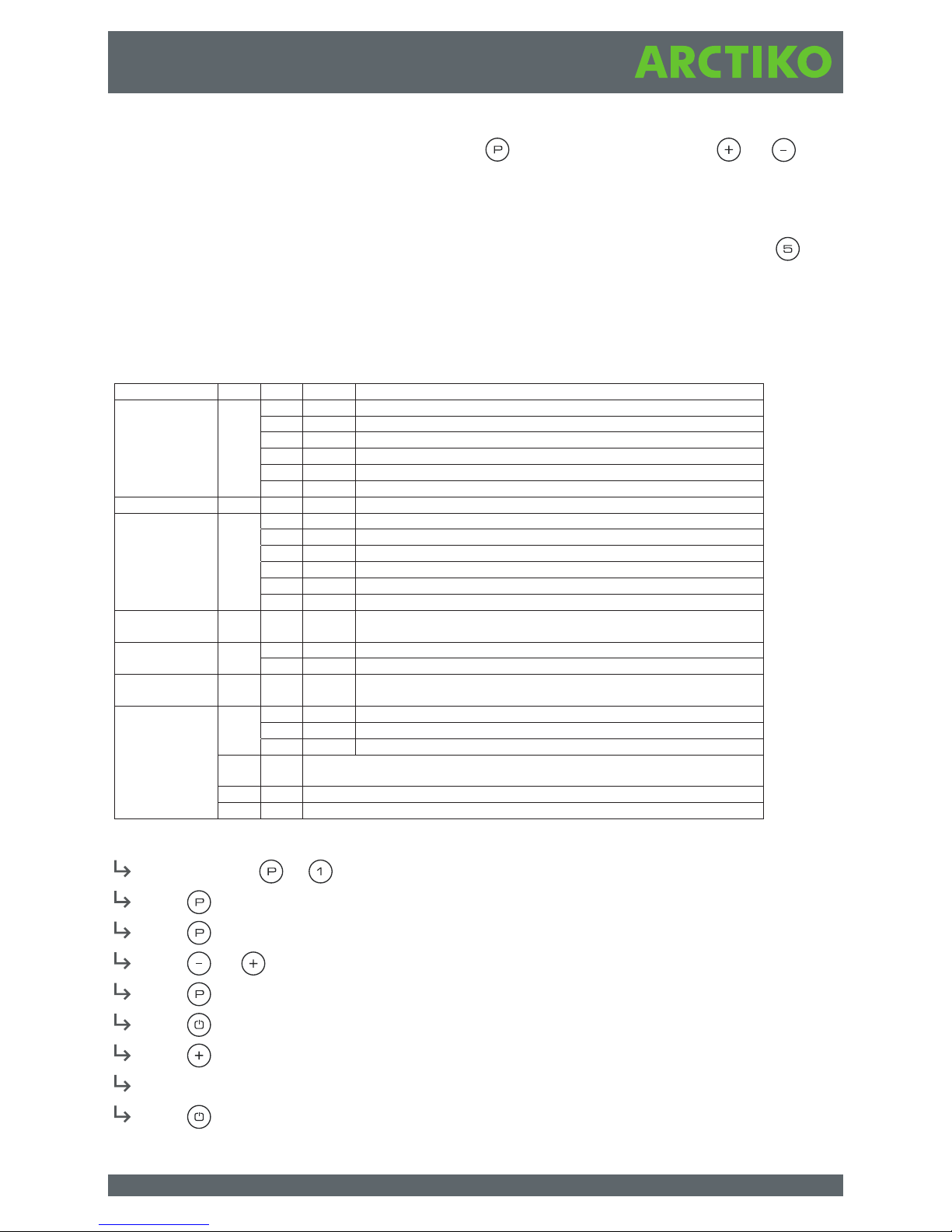

Setting the temperature

Temperature adjustments are done by holding the button and pressing either or

Confirmthe settings byletting go of thebuttons.

Lighting inside the cabinet

-Only applicableto cabinets with glass doors -

The settings for the lighting inside the cabinet can be turned oby pressing and holding

for 3seconds.

There are two settings:

1) Light turns on when the door is open(owhen closed)

2) Light is always on

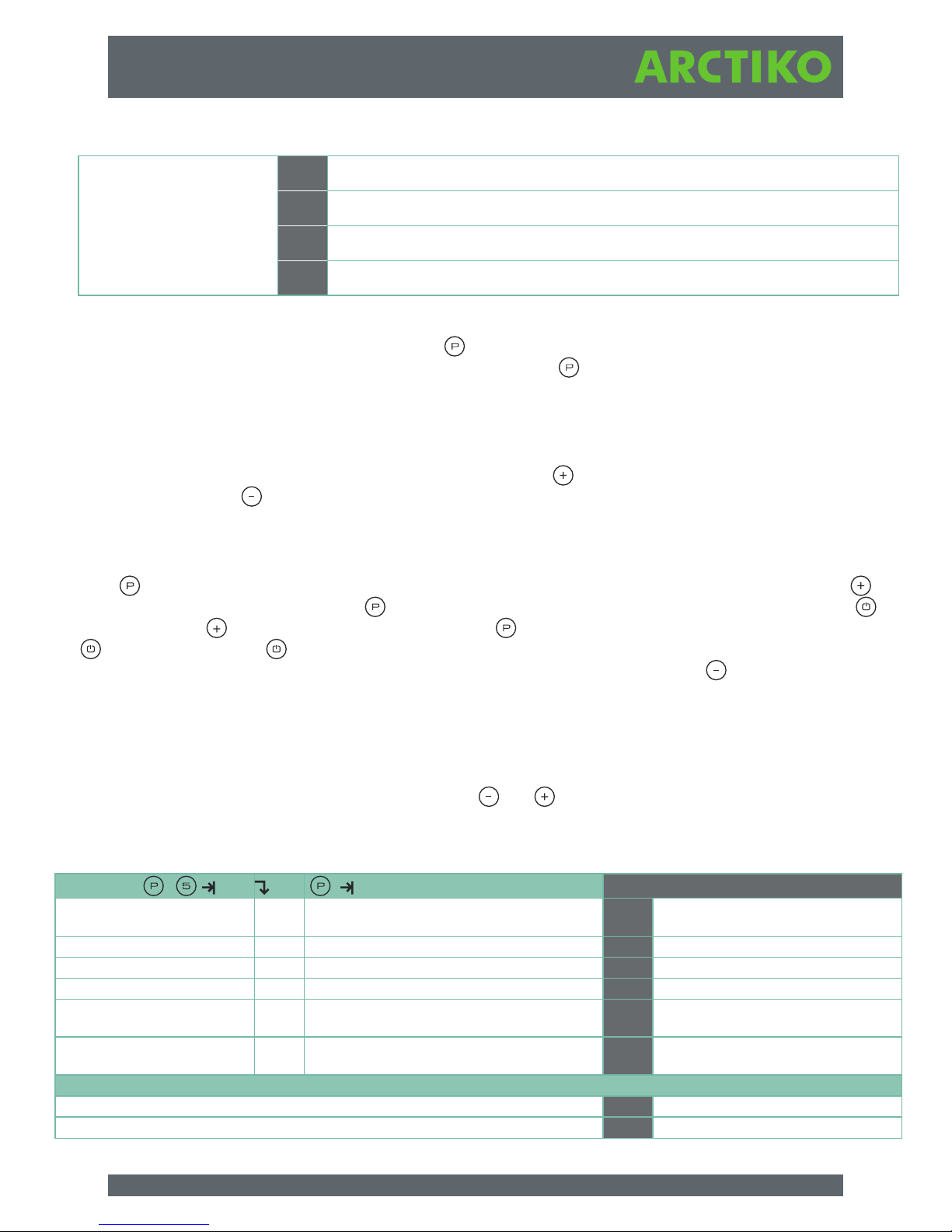

User menu and alarm settings

Example: Setting the upper limits for the alarms; LHL

Press and hold + until the display shows LAL

Press to select LAL,LHL is now shown in thedisplay

Press to select LHL, 25 is shown in the display

Press or to set thedesired value for theupper temperature limit

Press to conrm the set value

Press to return to LAL

Press to reach the next level, LLL

LHd,LLd, dA,dAd and bU are located on thesame level

Press three times to leave the user menu

Local alarm LAL LhL (°C) Upper temperature limit. Code for activated alarm: (A2)

LLL (°C) Lower temperature limit. Code for activated alarm: (A3)

Lhd (min.) Delay of uppe timil e r u ta repmet r

timil eru tar epmet rewo l f o yaleD ).n im( dLL

dA On/off Door alarm. Code for activated alarm: (A1). (1=on / 0=off)

mr a l a r ood f o ya l eD ) . n im( dAd

BU On/off Acoustic signal at alarms: Codes (A1), (A2), (A3). (1=on / 0=off)

External alarm EAL EhL (°C) Upper temperature limit Code for activated alarm: (A4)

ELL (°C) Lower temperature limit Code for activated alarm: (A5)

Ehd (min.) Delay of uppe timil eru tar epmet r

timil eru tar epmet rewo l f o yaleD ).n im( dLE

dA On/off Door alarm. Code for activated alarm: (A1). (1=on / 0=off)

mr a l a r ood f o ya l eD ) . n im( dAd

BU On/off Acoustic signal at alarms: Codes (A1), (A4), (A5). (1=on / 0=off)

Calibration of

sensors

cAL cA (°K) Offset settings of A-sensor. Reference sensor for the refrig. system

cE (°K) Offset settings of E-sensor. Reference sensor for display and alarms

cF (°K) Offset settings of F-sensor. Reference sensor for low temp. protection

Low-temp.

protection

ffo/no noitcetorp erutare pmet woL ffo/nO tcA PF

tES On Function test of the low temp. protection. Cut out of compressor =C4

erutarepmet tuo tuc eht fo gni t teS )C°( teS

ro sn es- F e ht no erutarepmet emit la er fo tuo d a eR )…( E r P

ALL Activation of escorted alarm limits. (FAS)=locked limits / (ESC)=follows set

points

sruoh 4 2 rep stsorfed fo rebmuN FEd

.)F ro E,A( ya l psi d eh t rof rosnes ecne re feR SPd