INDEX......................................................PAGE

SafetyPrecautions..............................................................3

Installingtheappliance...........................................................7

ElectricalConnection............................................................7

Information ...................................................................7

Descriptions of Refrigerator Parts and Their Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

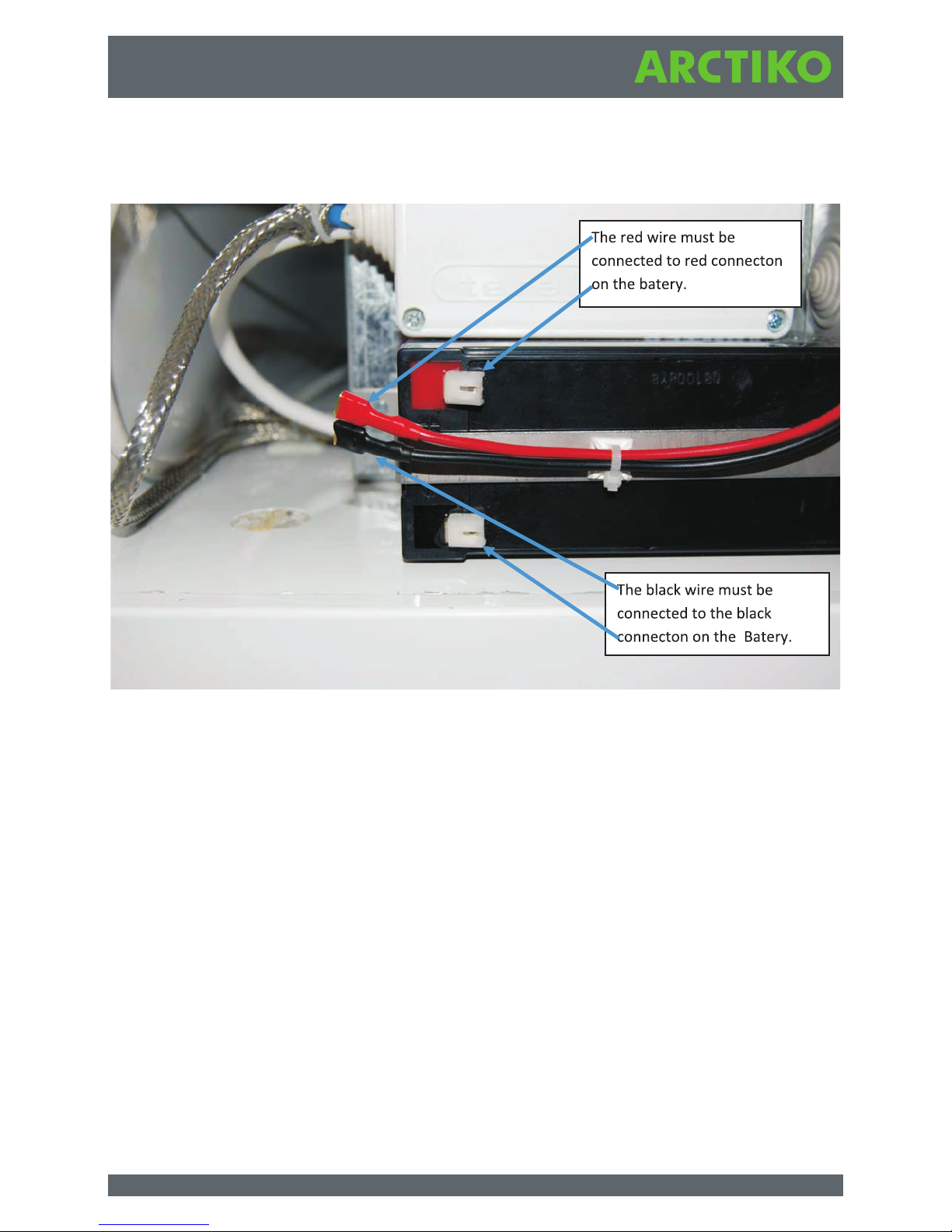

Before you start up the Refrigerator, you have to connect the Battery Backup . . . . . . . . . . . . . . . . . 10

HowtomounttheDoorHandle....................................................11

How to mount the Adjustable Devices in the Blood Storage Drawer . . . . . . . . . . . . . . . . . . . . . . . . . 12

LocationofRefrigerator .........................................................13

Installation...................................................................14

ControlPanel.................................................................15

DescriptionControlPanelforuser..................................................15

DescriptionControlPanelforengineer ..............................................16

Defaultsettings ...............................................................17

Operation....................................................................18

ChartRecorder................................................................19

ProperusageoftheRefrigerator...................................................23

Maintenance .................................................................24

CleaningtheRefrigerator ........................................................24

HowtochangetheFlourescentLightTube ...........................................25

Specifications.................................................................26

TheRatingPlate...............................................................28

After-Salesupport .............................................................29

DearCustomer................................................................29

SpareParts ..................................................................29

Guarantee ...................................................................29

BlockDiagramofMainPCBboard .................................................30

WiringdiagramforBBR500/700..................................................31

WiringdiagramforBBR1400.....................................................32