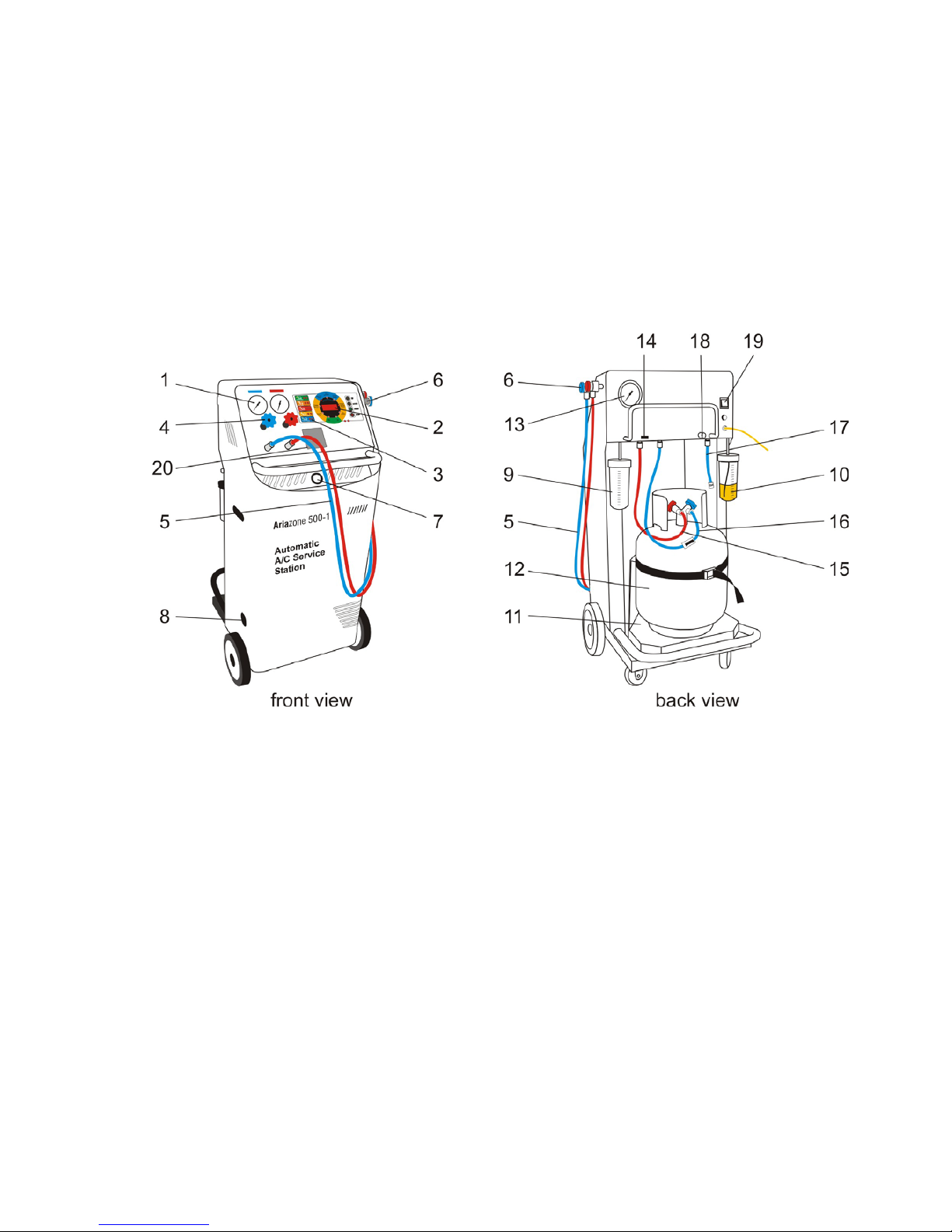

console, which allows the operator to connect the Ariazone system to the vehicle air-

conditioning system service ports.

6. Service Hoses Quick Couplers

Service hose quick couplers allows the operator to connect the Ariazone system, to the vehicle

air-conditioning system service ports without the risk of exhausting refrigerant in to the

environment.

7. Moisture Indicator - The moisture indicator is conveniently mounted on the console for

added protection to indicate the condition of refrigerant and filter change intervals. The

following colours correspond to the following moisture content,

Green or Blue Dry, Yellow or Pink Wet,

8. Vacuum Pump oil level - oil level must be checked when the pump is running, the oil level

should be even with the line on the sight glass. Under filling will result in poor vacuum

performance. Over filling can result in oil exhausting from pump vent.

9. Recovered Oil Drain Reservoir - A vessel of 250ml (8.75oz) is mounted on the right

rear of the unit to electronically gauge the amount of oil recovered from the air-conditioning

system, if any.

10. Oil Storage Reservoir - A vessel of 250ml (8.75oz) is mounted on the left rear of

the unit to electronically inject the oil back in to air conditioning system, or to select the

desired amount of oil to be injected.

11. Cylinder platform / Electronic scale – To electronically display amount of refrigerant in

storage cylinder, being recovered or charged in to air-conditioning system.

12. Refrigerant Cylinder 12 or 25kg is used to store the recovered and purified refrigerant.

13. Cylinder Non-condensable Indicator - A large pressure gauge is mounted on the back

upper side of Ariazone unit to indicate to the technician of any non-condensable (air) built up

in the storage cylinder.

14. PC communication port (if fitted)

15. Cylinder vapour hose

16. Cylinder liquid hose with ball valve

17. Adapter hose

18. Vacuum port - To attach micron gauge when required

19. Power switch

20. Printer