owner’s manual

3

When using electrical appliances, basic safety precaution should always be followed including the following:

READ ALL INSTRUCTION BEFORE USE

• All electrical wiring must be in compliance with local, state, and national electrical code.

• This product must be properly grounded before use to reduce the risk of electrical shock.

• Proper sealant should be used to prevent leakage.

• Oil and fuel is ammable and explosive in certain condition. Only use this product in a well

ventilated area.

• Keep cigarette, smoke, sparks, or any similar matter away from the unit.

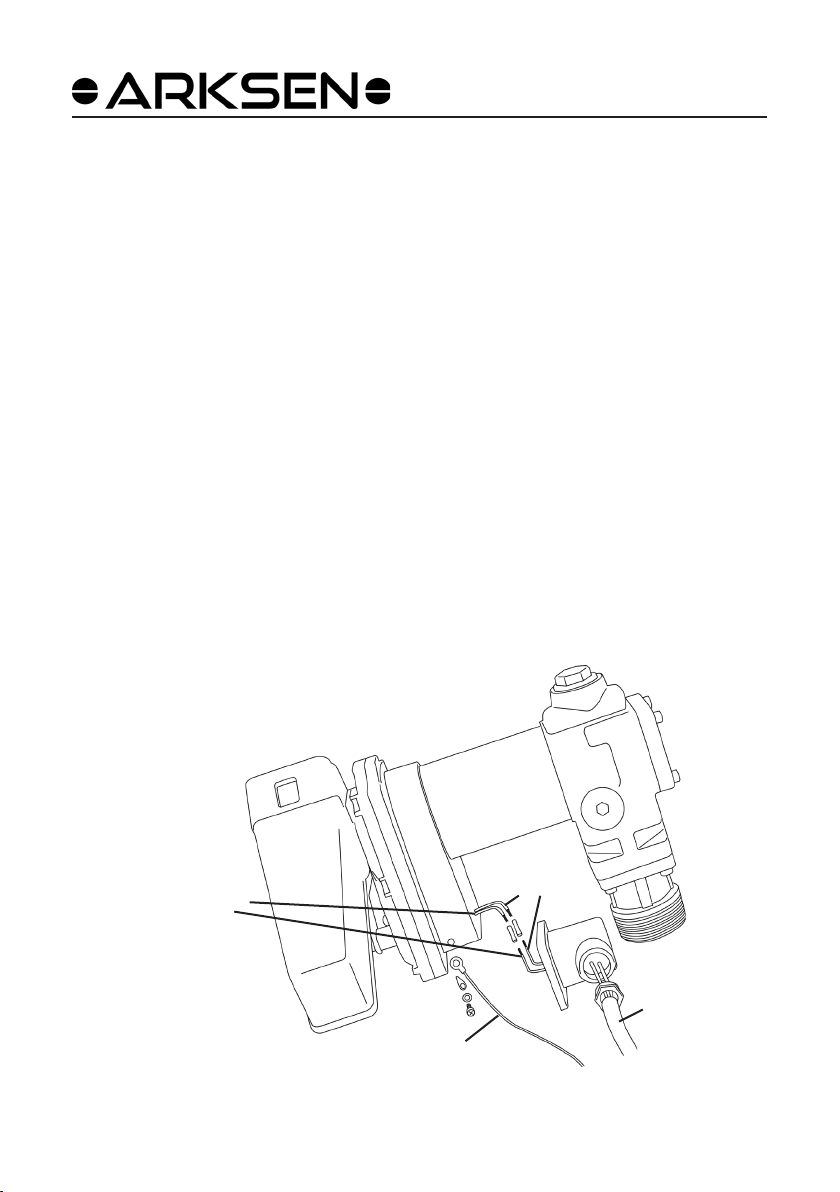

• To avoid accident and equipment damage, check the unit every time before use.

• Keep the unit on a level surface to prevent fuel leak.

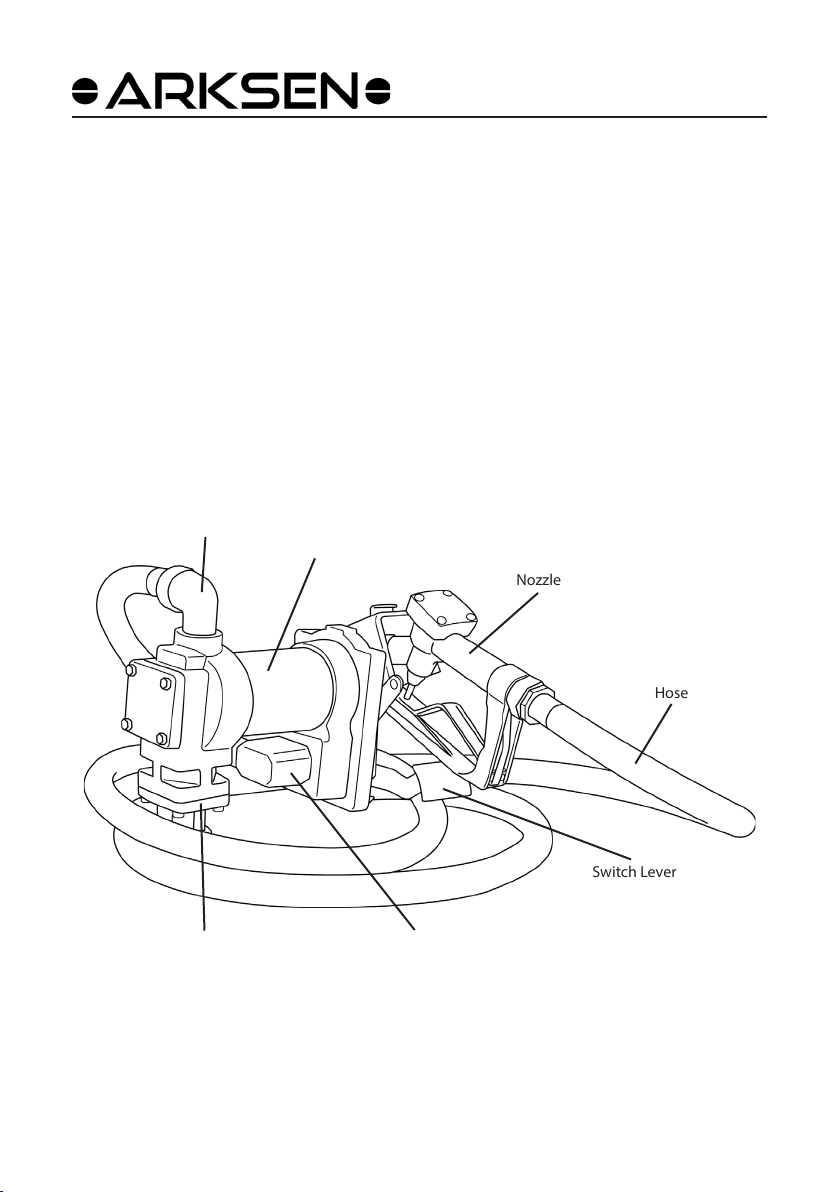

• Operators of this unit must be trained and know how to stop the unit quickly and understand

the operation of all controllable parts. Untrained operators should not be allowed to use this

equipments.

• Keep children and pets away from operation area.

• Do not use this product other than intended use.

• Do not operate this product with damaged parts, pipes, or cord or after the unit malfunctions, or

has been dropped or damaged in any manner.

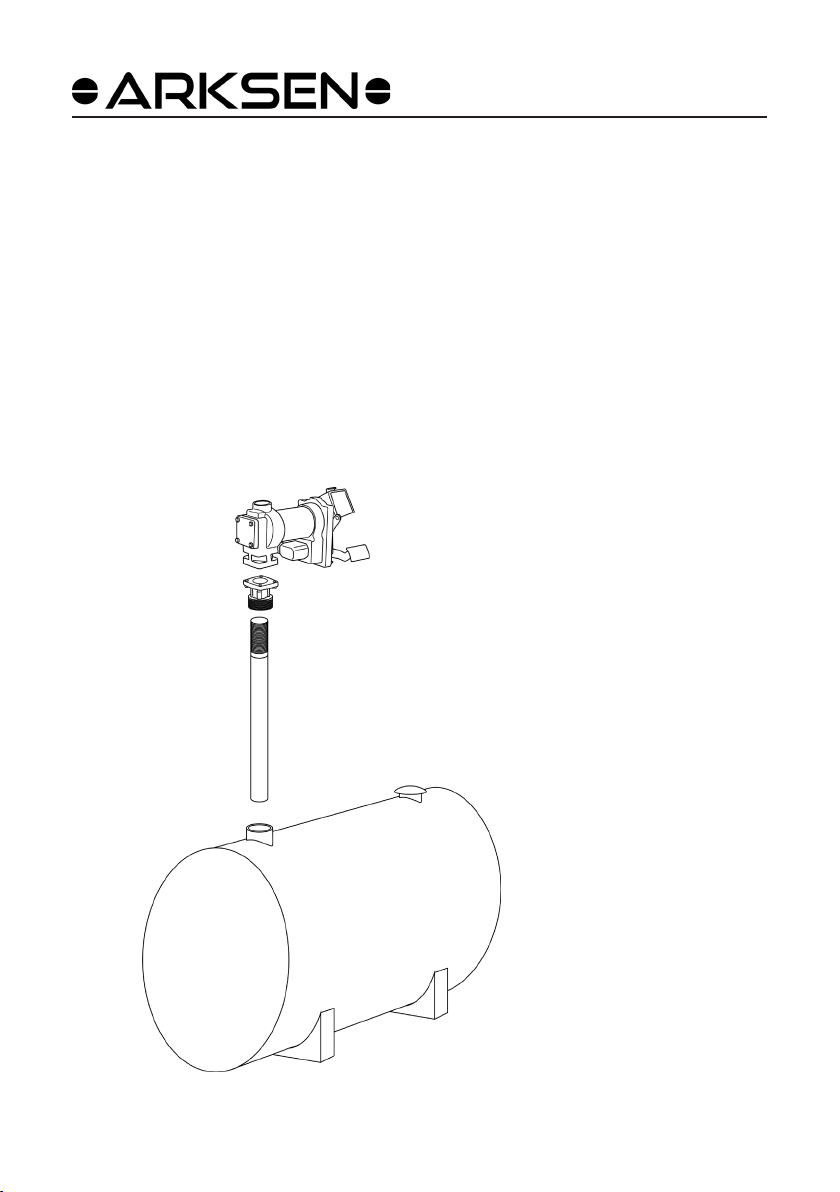

• Fuel storage tank must be securely anchored to prevent shifting or tipping when full or empty.

• Do not use this product to pump water or any other liquid intended for human consumption.

• Do not use this product to transfer uid to aircraft.

SAVE THESE INSTRUCTIONS