B10 -156•B52•09/22•GB •p. 2 of 8•www.armano-messtechnik.com

Operating Instructions

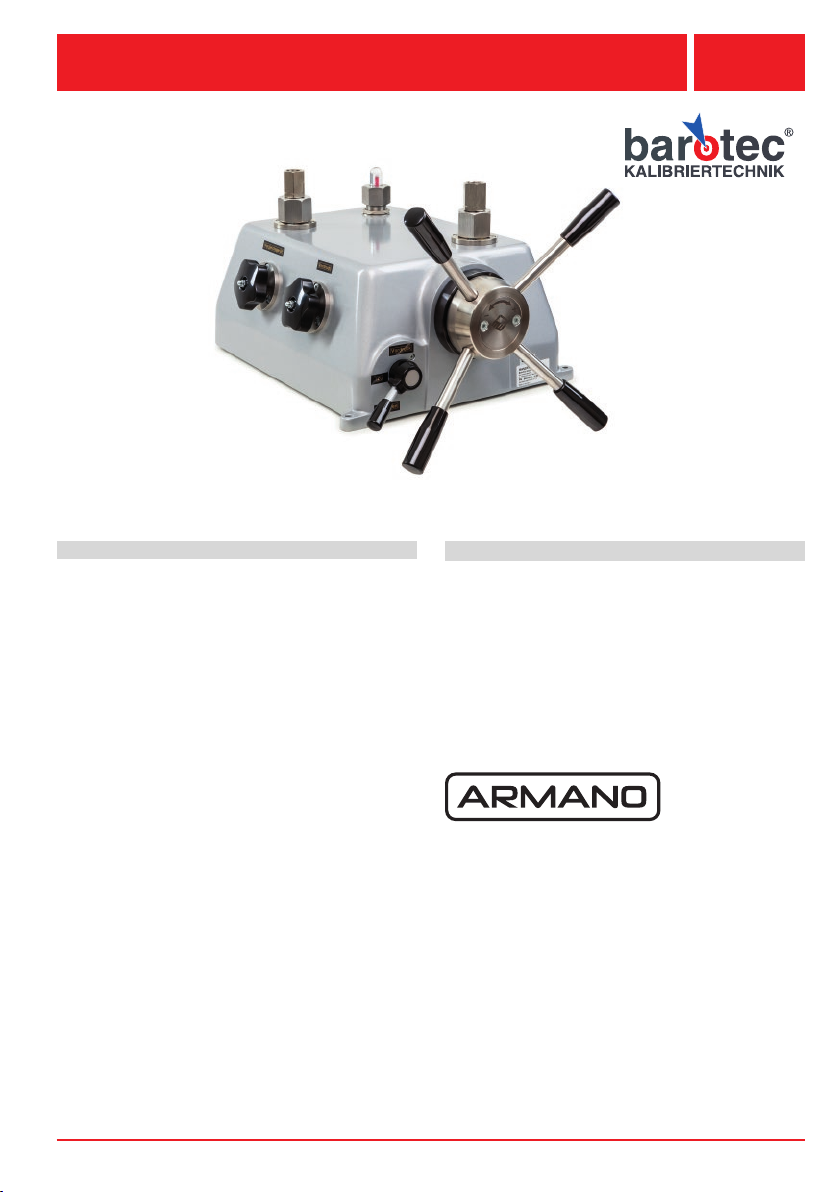

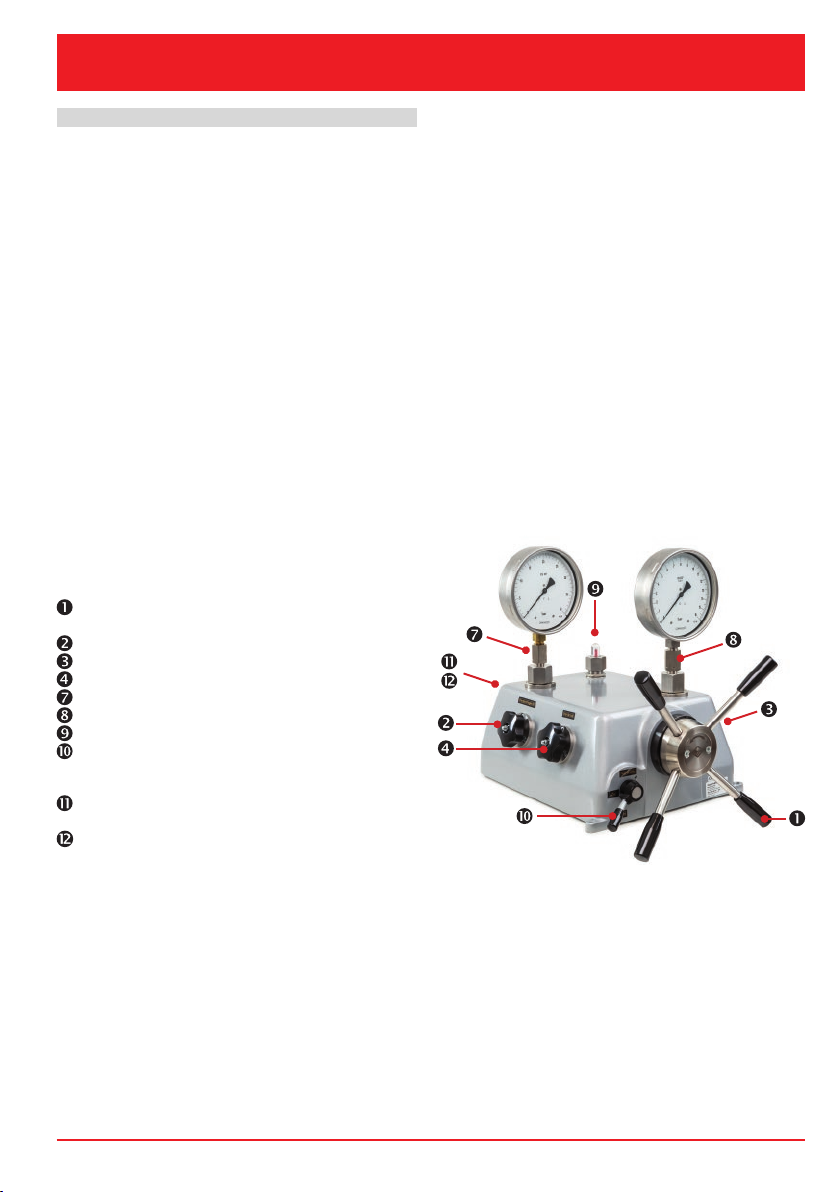

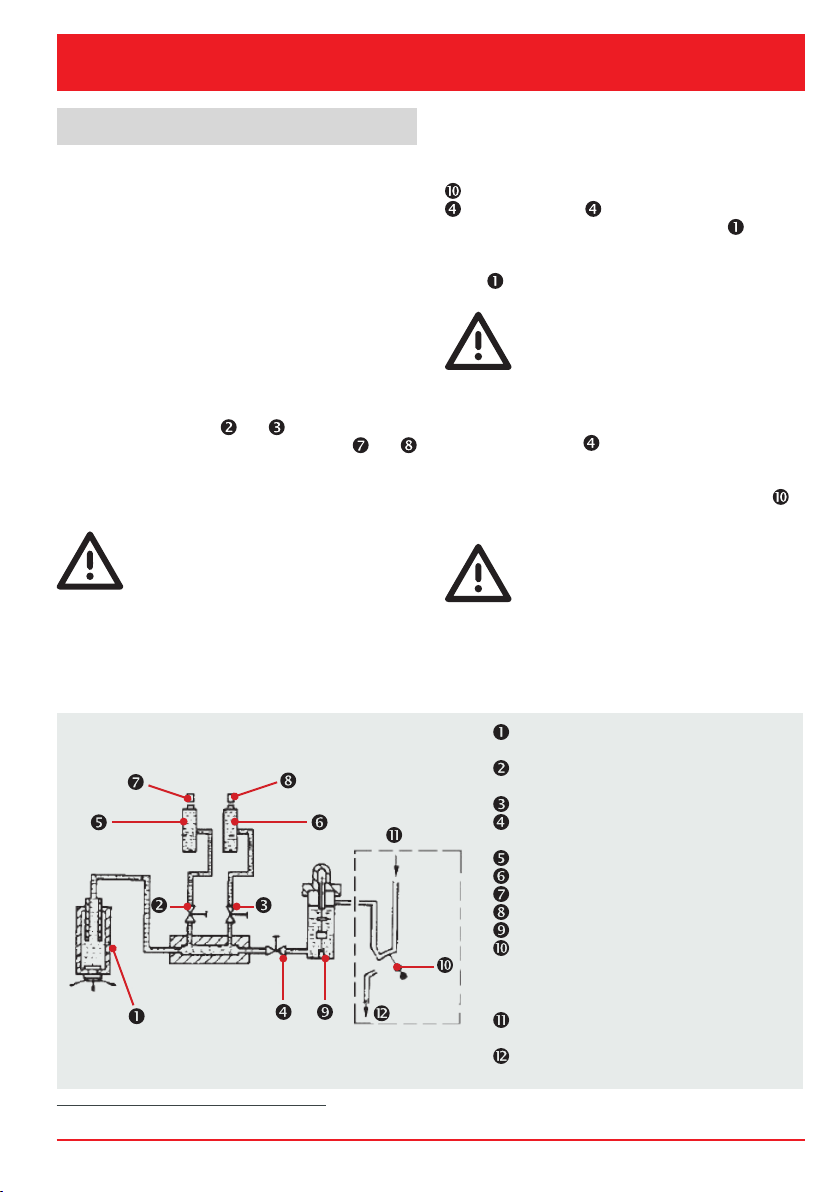

Comparison Pumps PS 600-G / PS 1000-G

1.1 Pictographs Used

In this manual, pictographs are used as hazard warnings.

Particular information, instructions and restrictions

designed for the prevention of personal or substantial

property damage:

WARNING! Is used to warn you against an

imminent danger that may result in personal

injury or death.

IMPORTANT!Is used to warn you against a

possibly hazardous situation that may result in

personal, property or environmental damage.

CAUTION!Is used to draw your attention

to important recommendations to be ob-

served. Disregarding them may result in

property damage.

The following symbol highlights

actions you have to conduct

or

instructions that have to be strictly observed.

1.2 Exclusion of Liability

We accept no liability for any damage or malfunction

resulting from incorrect installation, inappropriate use

of the device or failure to follow the instructions in this

manual.

2. Safety Instructions

Please read this operating instruction thoroughly be-

fore operating the comparison pump.

Disregarding the containing warnings, especially the

safety instructions, may result in danger for people,

the environment, and the device and the system it is

connected to.

The comparison pump corresponds with the state of

engineering at the time of printing. This concerns the

operating mode and the safe operation of the device.

In order to guarantee that the device operates safely,

the operator must act competently and be conscious

of safety issues.

The ARMANO Messtechnik GmbH provides support

for the use of its products either personally or via rele-

vant literature. The customer veries that our product

is t for purpose based on our technical information.

The customer performs customer and application

specic tests to ensure that the product is suitable for

the intended use. With this verication, all hazards and

risks are transferred to our customers. Our warranty

expires in case of inappropriate use.

Qualied personnel:

The personnel that is charged for the installation,

operation and maintenance of the comparison pump

must hold a relevant qualication. This can be based

on training or relevant tuition. The personnel must be

aware of this manual and have access to it at all times.

General safety instructions:

• In all work, the existing national regulations for ac-

cident prevention and safety at the workplace must

be complied with. Any internal regulations of the op-

erator must also be complied with, even if these are

not mentioned in this manual.

• Use the comparison pump in its perfect technical

condition only. Damaged or defective instruments

need to be checked immediately and replaced if

necessary.

• Only use appropriate tools for mounting, connect-

ing and dismounting the comparison pump.

• Nameplates or other information on the device shall

neither be removed nor obliterated, since other-

wise any warranty and manufacturer responsibility

expires.

Special safety instructions:

Warnings, which are specically relevant to individual

operating procedures or activities, are to be found at

the beginning of the relevant sections of this operating

instruction.