Page | 2 Ascento Group Australia 37 Export St, Lytton, Brisbane, QLD 4178 P: 1800807604 Version: 2018-03-20

4. IMPORTANT re INSTALLATION: This pump MUST NOT be installed in any manner that if it were to leak that it would cause

damage or loss to property or persons. It MUST be installed in a well-ventilated and drained area. All warranty is void if this

condition is not heeded and no liability can be accepted in the case of damage or loss caused by failing to comply with this condition

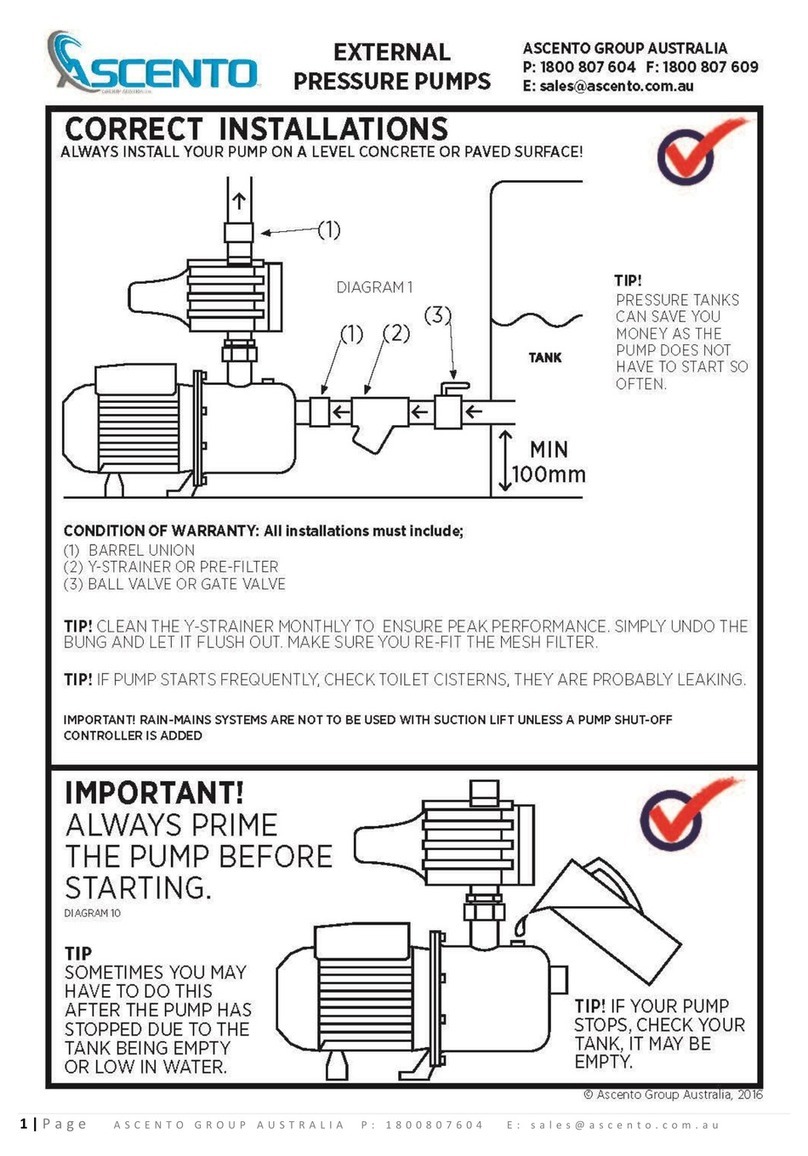

5.BASE must be LEVEL Fix the pump in place through the footplate using suitable fasteners, on a stable, level surface –must NOT

be sloping even slightly.

6. IMPORTANT re PUMP NOISE: Avoid installing near bedrooms or neighbours bedrooms. These are JET pumps and due to their

self-priming design they typically make more noise than a MULTISTAGE Pump. This is a feature of the pump design, it is not a fault,

and is not a cause for warranty claims, as it is not a product fault. If noise is likely to cause problems, we recommend that you use a

MULTISTAGE Pump.

7. (a) PIPE SIZE AND TYPE: Install the pump as near the water supply as possible to reduce the length of suction pipe. We

recommend heavy duty flexible suction hose for the inlet (Suction Pipe) but whatever pipe is used it must be no less than 25mm

Internal Diameter (30mm is better), and heavy-duty pressure hose or similar for the outlet, we recommend 25mm Internal Diameter

for the delivery pipework for the best performance, 19mm Internal Diameter minimum for the discharge. If the pump is for “Whole

of house” supply we strongly recommend that 25mm Internal Diameter piping is used throughout the house, and is only reduced to

connect to the fixtures as required, this will ensure that the pump delivers best performance and efficiency, saving the user money

over the long-term. Use as few bends as possible, every bend reduces performance.

7. (b) MORE INFO RE PIPE SIZE: Pressure of the water at the discharge (taps, showers, irrigation etc) is affected by the pipe size.

The SMALLER your pipes, the LOWER the pressure will be at discharge. Example: 13mm ID pipe over 20 metres at 30Lpm will reduce

pressure at discharge by 240kPa (2.4bar) - whereas if 25mm ID pipe is used for 20 meters at 30Lpm it only reduces pressure by a

miniscule 10kPa. Smaller pipe also means that more power will be used as the pump has to work harder to overcome the extra

back-pressure from small pipes. A small short-term saving (in the cost of the pipes) will become a long-term liability.

8.SEAL JOINTS Ensure all fittings and joints are watertight and airtight, especially in suction-lift applications.

9. INSTALLATION AND ELECTRICAL WIRING must adhere to state and local codes and must be completed before priming the pump.

These pumps come with an earthed power plug and all electrical installations must be earthed. Any Electrical work must be

performed by a licenced Electrician. The installation must also comply with applicable Plumbing Regulations, it is the installers

responsibility to ensure compliance.

10. IMPORTANT re SAFETY SWITCH (RCD);

(a) The Pump must be connected to a suitable power circuit with an integral RCD (safety switch) having a rated residual operating

current not exceeding 30mA, in the circuit breaker. Disconnect the pump from power supply when people are in the water, or

when servicing or repairing the pump. All warranty is void if this instruction is not followed. Note: Plugging into existing outlets may

cause low voltage supply to the motor, causing blown fuses, tripping of motor overload, or burnt out motor, which will not be

covered by the Warranty.

(b) Surge Protection - We recommend that a surge protector is used to protect the electronics of this pump, as damage due to

power surges is not covered by the Warranty.

11. MAINS PRESSURE BOOSTING This is a specialized type of application, and must be completed by a Qualified Plumber or Pump

Technician who is competent and licenced to perform this type of installation.

12. VOLTAGE of power supply must match the voltage of the pump –refer to the nameplate on the pump. Do not run on generator

power from low quality/old generators. If you only have generator power, you may need to have the Pressure Controller removed

and replaced with a Pressure Tank and Switch, at additional cost. The Pressure Controller will be damaged by the voltage

fluctuations caused by power supplied by low quality generators. High quality “Sine-Wave” generators are usually acceptable but

we cannot guarantee this, as we have no control over the generator that you use, it is your responsibility to ensure the generator

used is fit for the purpose.

13. WARNING: these pumps are not designed for, and must not be installed in locations classified as hazardous.

14. THE FOLLOWING MAY CAUSE SEVERE DAMAGE TO THE PUMP AND WILL VOID WARRANTY;

(a) Using an extension cord to power the pump.

(b) Cutting the earth pin off the plug or using an adapter fitting or double adapter.

(c) Working on the pump while connected to the power supply.

(d) Removing motor housing, or dissembling the pump housing, except by a qualified technician

(e) Pumping chemicals or corrosive liquids or flammable liquids.

(f) Pumping hot liquids (Exceeding 40° Centigrade)

(g) Using a generator for power supply - see 12