2

Finishing the wood

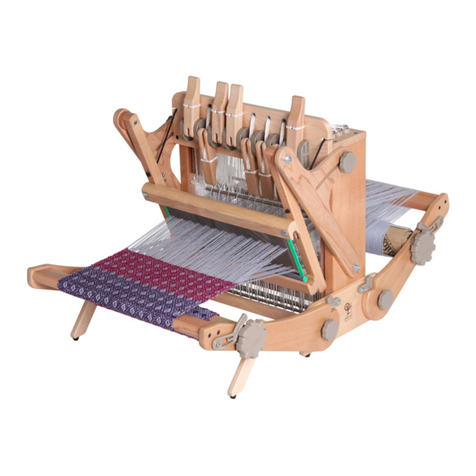

The Sliver Beech tree is a native of New Zealand and has a lovely variety of colour and grain.

This Jack Loom has been finished with a water based lacquer to protect the kiln dried timber from climatic changes and enhance its

natural character. To repair and restore the finish use Ashford Wax Polish to enhance the natural beauty of the wood.

Before Assembly

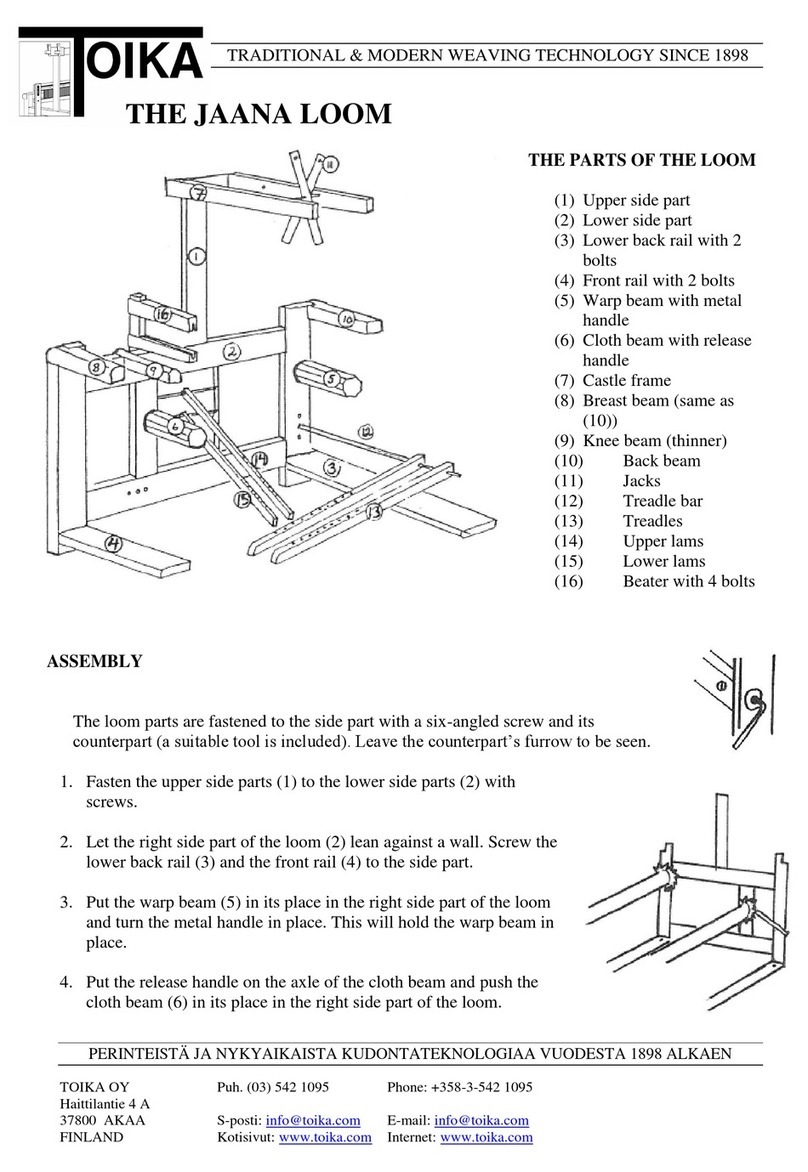

• Please read these instructions completely, identify all parts and hardware and note the assembly sequence.

• BOLTS. Check and sort the sizes and quantities against the full-size drawing on page 4.

• Rub candlewax on the threads of the woodscrews to make assembly easier.

Check hardware against full

size illustration.

To make assembly easier use

candle wax on the screws.

ASSEMBLY INSTRUCTIONS FOR

THE ASHFORD JACK LOOM

Tools Required

Hints

More Information

The Wheel Magazine

Ashford’s annual fibrecraft magazine.

Spinning, weaving, felting, dyeing and

knitting projects, patterns and articles

from around the world. To receive

the glossy version delivered to you,

subscribe at:

www.ashford.co.nz/subscribe

How-to videos on You Tube

Watch our how-to videos on You Tube.

www.youtube.com/user/AshfordHandicrafts

Facebook

Join us on facebook.

www.facebook.com/ashford.wheels.looms

SpannerCandle wax Wood glue Oil

Screwdriver, hammer, candlewax, wood glue, light lubrication oil, adjustable spanner and a ruler.