Druck PV 411 User Manual

Page iii K258 Issue No. 1

CONTENTS

Title page

Introduction ............................................................................................... 1

Pneumatic pump .................................................................................... 1

Hydraulic pump ...................................................................................... 1

Specification ........................................................................................... 3

Operation ............................................................................................... 4

Pressure/ acuum configuration ............................................................. 4

Connecting the pump ....................................................................... 5

Selector al e ................................................................................... 5

Scissor-action handles limit adjuster ................................................ 6

Pneumatic Operation ........................................................................................ 7

Volume adjuster ................................................................................ 7

Generating pneumatic pressure and acuum ................................... 8

Pressure ............................................................................................ 8

Vacuum ............................................................................................. 8

Hydraulic Operation ........................................................................................ 10

Fluid reser oir ....................................................................................... 10

Fitting ......................................................................................... 12

Filling ......................................................................................... 12

Priming the system .............................................................................. 13

Vacuum priming......................................................................... 13

Pre-filling .................................................................................... 14

Setting pressure relief al e ................................................................ 14

Generating hydraulic pressure ............................................................. 15

Multimedia ........................................................................................... 16

Flushing ..................................................................................... 16

Fault finding .......................................................................................... 17

Appro ed ser ice agents ..................................................................... 18

Annex A

Returned Goods Procedure ................................................................. 19

ILLUSTRATIONS

Figure title page

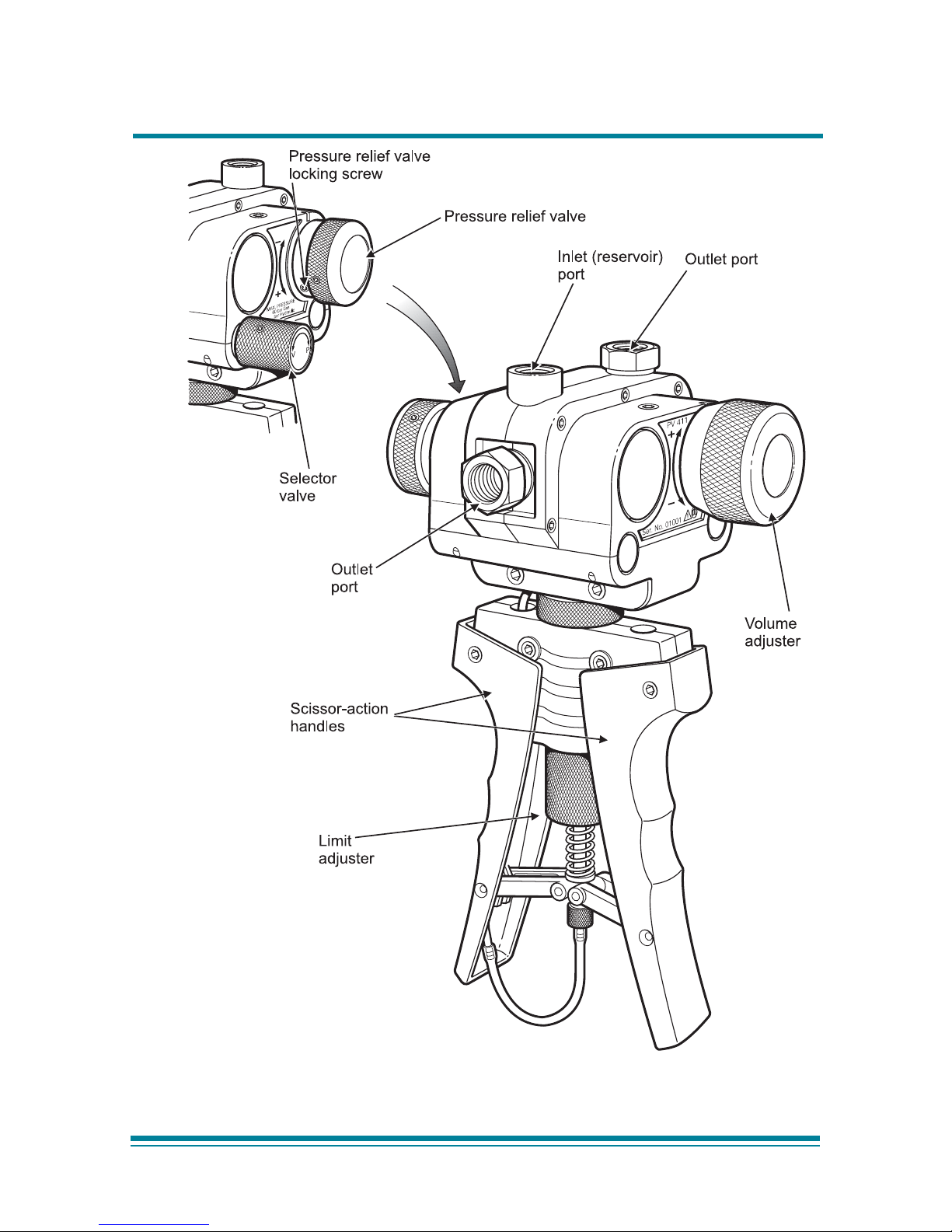

1 General iew ............................................................................... 2

2 Fitting the reser oir ................................................................... 11