3. Add water to the tank until water level is clearly

over the bottom of the lter basket. The water

must be lled to this level before each wash cycle.

The pump will pulsate if the water level is too low.

4. Set the Thermostat

between 135 - 175 Degrees.

5. Turn on the Breaker (if hard wired) that controls the Machine or plug in the power cord.

6. Turn the Heater Switch to the On Position.

7. Please use a thermometer (thermometer not

included) to measure the temperature of the

water. When the water reaches the temperature

you have set the thermostat to (this may take

up to an hour) *add the recommended style

detergent directly to the lter basket. Be sure to

follow the detergent manufacturer’s directions

regarding the amount of detergent to add.

Failure to follow the procedure outlined could

result in foaming incident and would result of

restarting the startup procedures.

*Pure Clean #10 is the recommended detergent (that also comes with the spray wash cabinet). It is an

Industrial Cleaner/Degreaser designed to remove dirt and oil while being concentrated, biodegradable,

nontoxic, nonammable, and non-corrosive. At a dilution of 3% (1:30) with water, heated to 140 F, Pure

Clean #10 eectively removes oils and greases. Due to Pure Clean #10’s low residue formula, spray

nozzles stay clean from soil build-up. No rinsing is required, single-stage washing system is practical.

Parts washed in Pure Clean #10 and dried are protected from rust for 7 to 15 days. Pure Clean #10

cannot be shipped via UPS/Fed Ex; it must be shipped via freight carrier. NFPA/HMIS: Health [2]; Flammability [0];

Reactivity [1]; Protective Equipment [D]

If Pure Clean #10 is not an option, you must use a LOW FOAMING detergent with rust inhibitors. Use

detergent strong enough to do the job but not so strong that it attacks the metal substrate. Liquid

detergent is to be used. Powdered detergent contains a high amount of silica. This makes it very

abrasive and more caustic as it dries on metal. Liquid detergent rinses much more completely and is the

best type of detergent for your Machine. Read instruction manual on soap container.

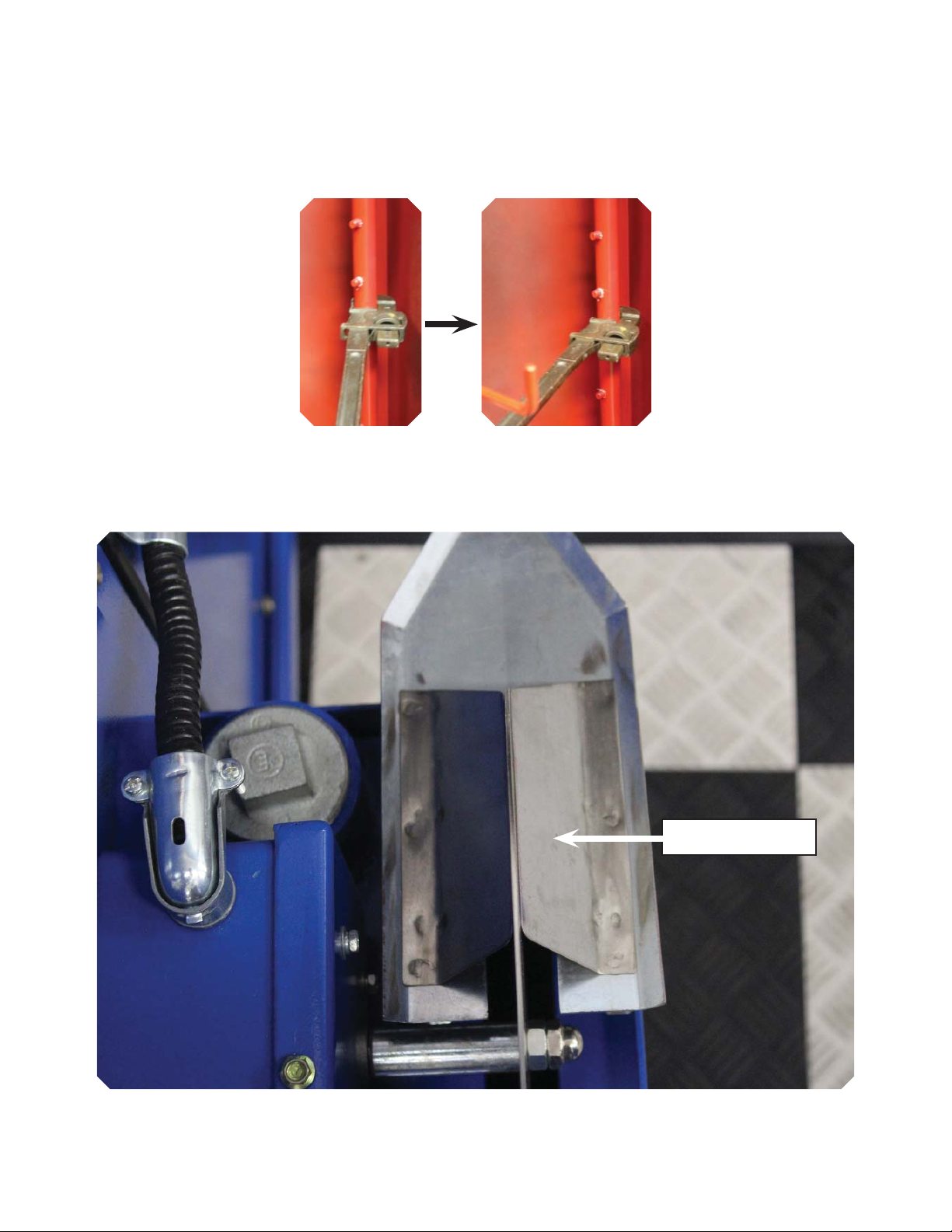

Filter Basket