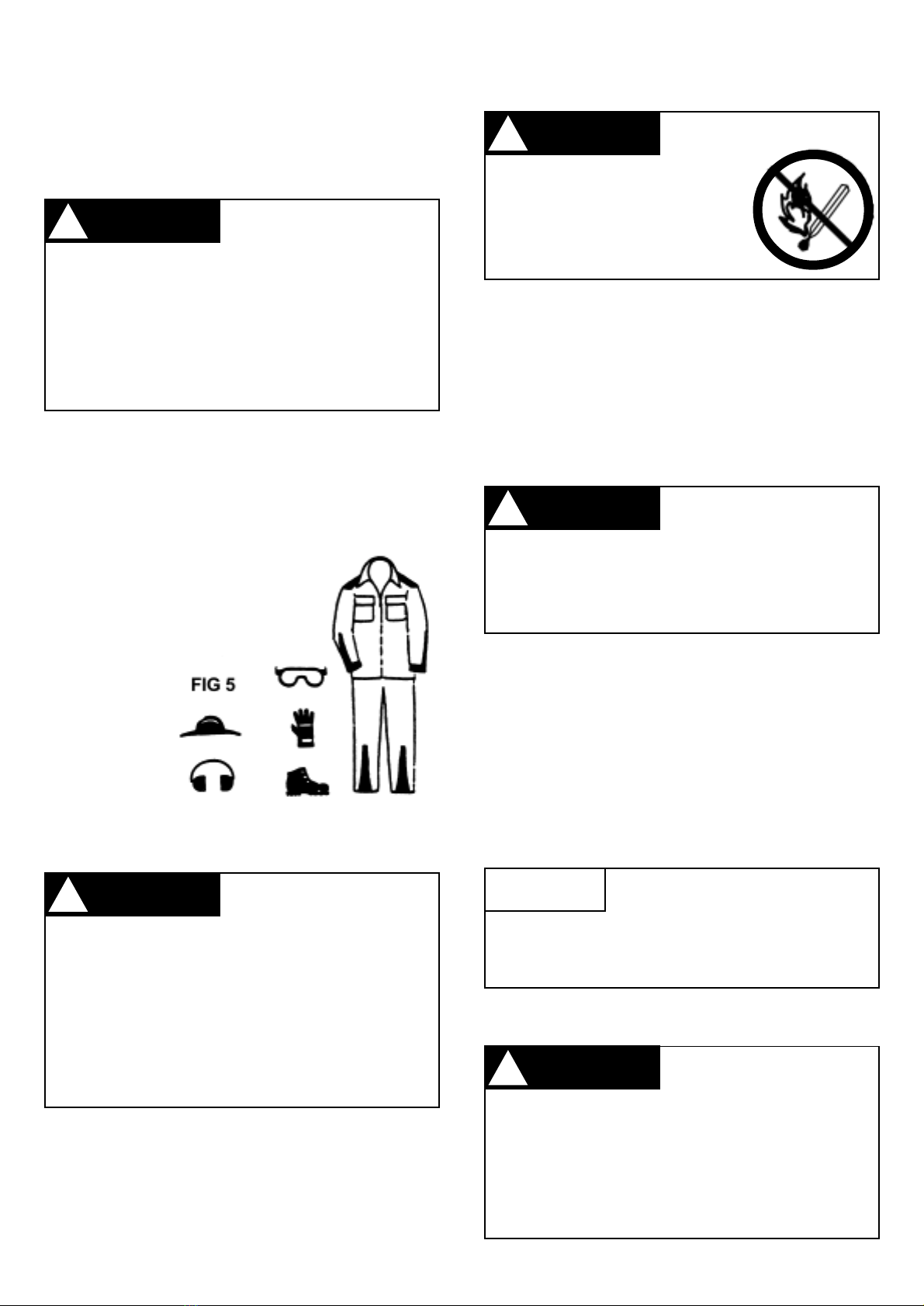

Failure to obey a safety

warning can result in

injury to yourself and others.

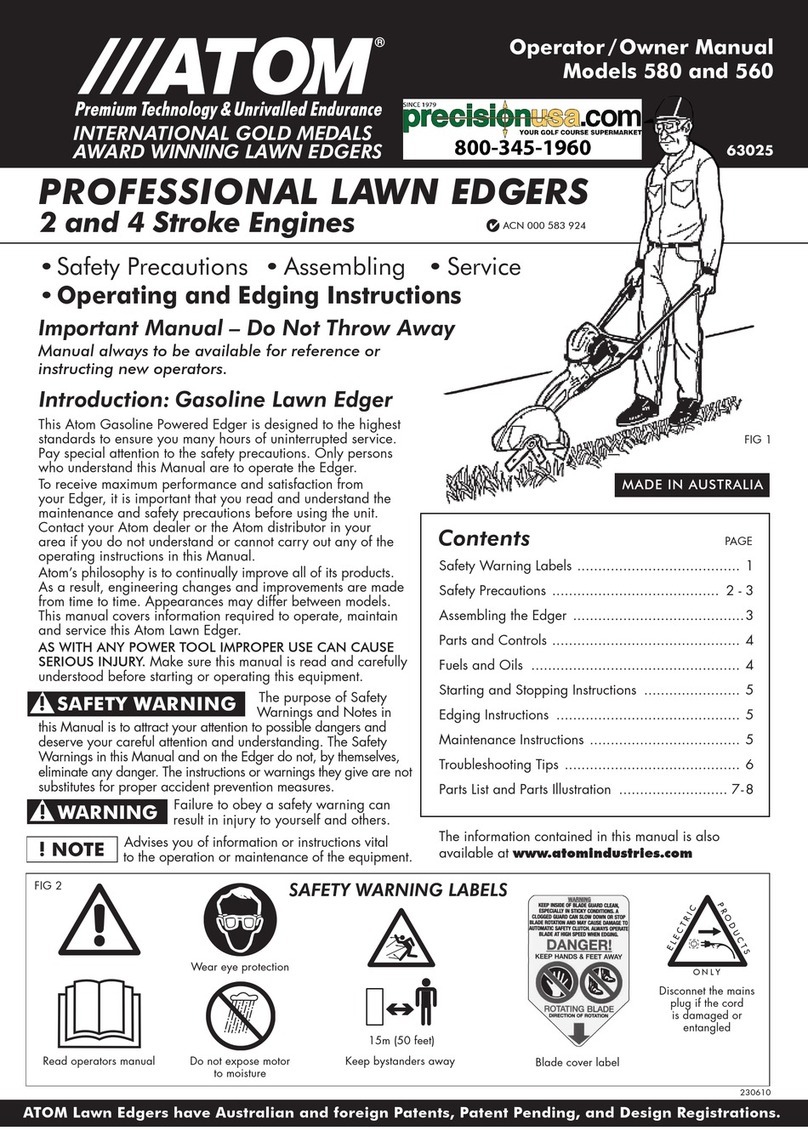

THE PURPOSE OF SAFETY WARNING AND NOTES IN THIS

MANUAL IS TO ATTRACT YOUR ATTENTION TO POSSIBLE

DANGERS AND THE EXPLANATIONS WITH THEM DESERVE YOUR CAREFUL ATTENTION AND

UNDERSTANDING. THE SAFETY WARNINGS IN THIS MANUAL AND ON THE EDGER DO NOT, BY

THEMSELVES, ELIMINATE ANY DANGER. THE INSTRUCTIONS OR WARNINGS THEY GIVE ARE NOT

SUBSTITUTES FOR PROPER ACCIDENT PREVENTION MEASURES.

INTRODUCTION

This Atom Gasoline Powered Lawn Edger is designed

to the highest standards to ensure you many hours of

uninterrupted service.

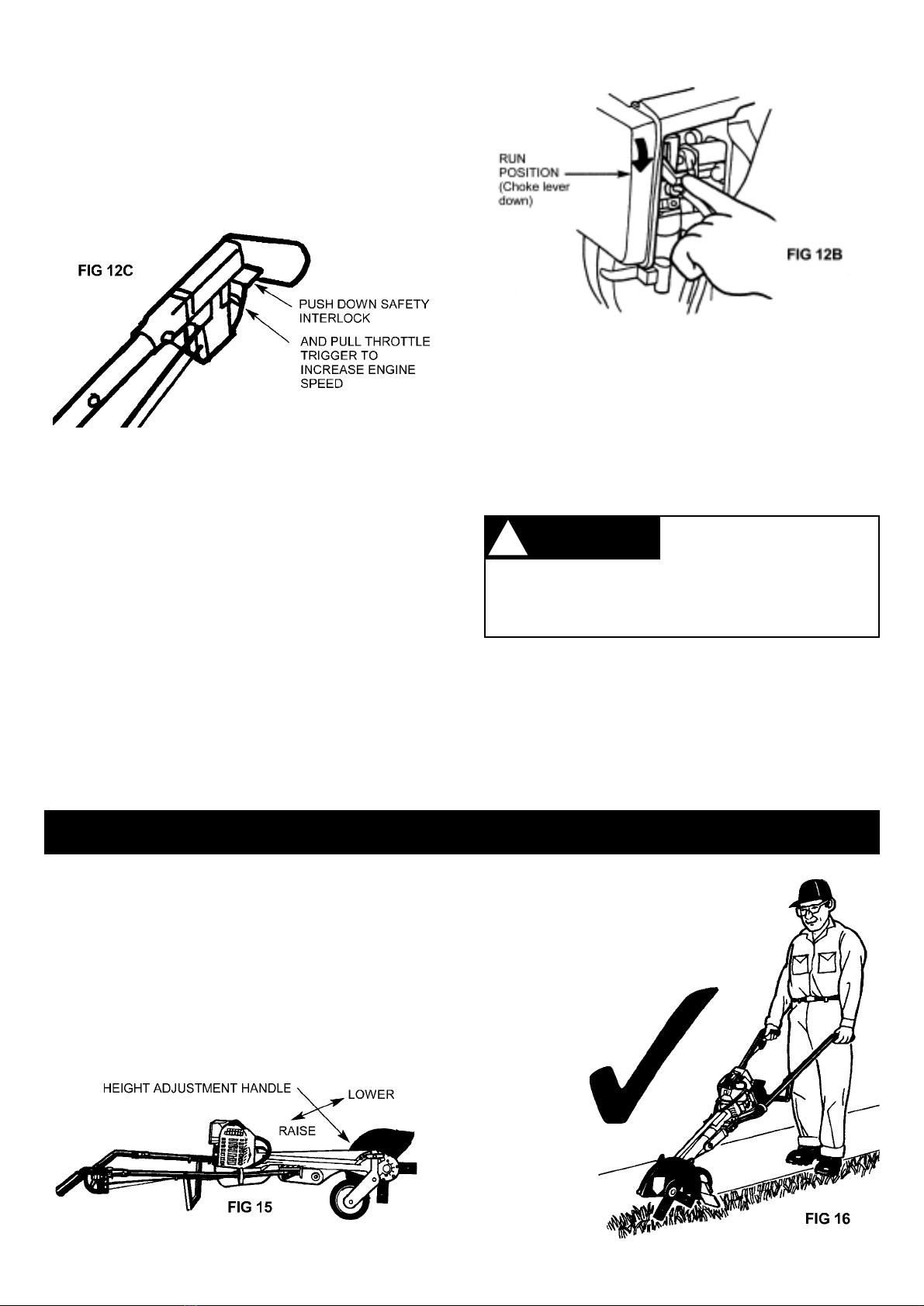

Pay special attention to the safety precautions outlined

on pages 2 to 5. Only persons who understand this

Manual are to operate the Lawn Edger.

Toreceivemaximumperformanceandsatisfactionfrom

your Lawn Edger, it is important that you read and

understand the maintenance and safety precautions

before using the edger. Contact yourAtom dealer or the

Atom distributor in your area if you do not understand or

cannot carry out any of the operating instructions in this

Manual.

Atom’s philosophy is to continually improve all of its

products. As a result, engineering changes and

improvements are made from time to time. If the

operating characteristics or the appearance of your

Atom Edger differs from those described in this

manual, please contact your Atom dealer for

information and assistance. Call (02) 9810 0194

(withinAustralia) for your nearest servicing dealer.

NOTE: OUTSIDE AUSTRALIA REFER TO BACK

COVERPAGE.

CONTENTS

Parts and Controls.................................................2-3

Safety Precautions ................................................3-5

Assembling the Lawn Edger .....................................6

Fuel and Oil..............................................................6

Starting and Stopping Instructions ..........................7-8

Edging Instructions

Blade Replacement.........................................10

Lubrication of Gears ........................................ 11

Spark Plug ...................................................... 11

AirFilterMaintenance...................................... 11

Removing Blade Cover ................................... 11

Carburettor Adjustment ...................................12

TroubleShootingTips......................................13

Parts List and Exploded View ............................14-15

At the rear of this manual is a workshop manual for the

lawnedgerbody.ForfullHondaengineinstructions and

maintenance, please refer to the separate “Honda

Owner’s Manual” supplied.All service and warranty on

your Honda engine can be done by your nearest

approved Honda dealer.....................................16-19

Warranty ................................................................20

PARTS & CONTROLS

1,2 The handles of the Lawn Edger are held by both

hands.

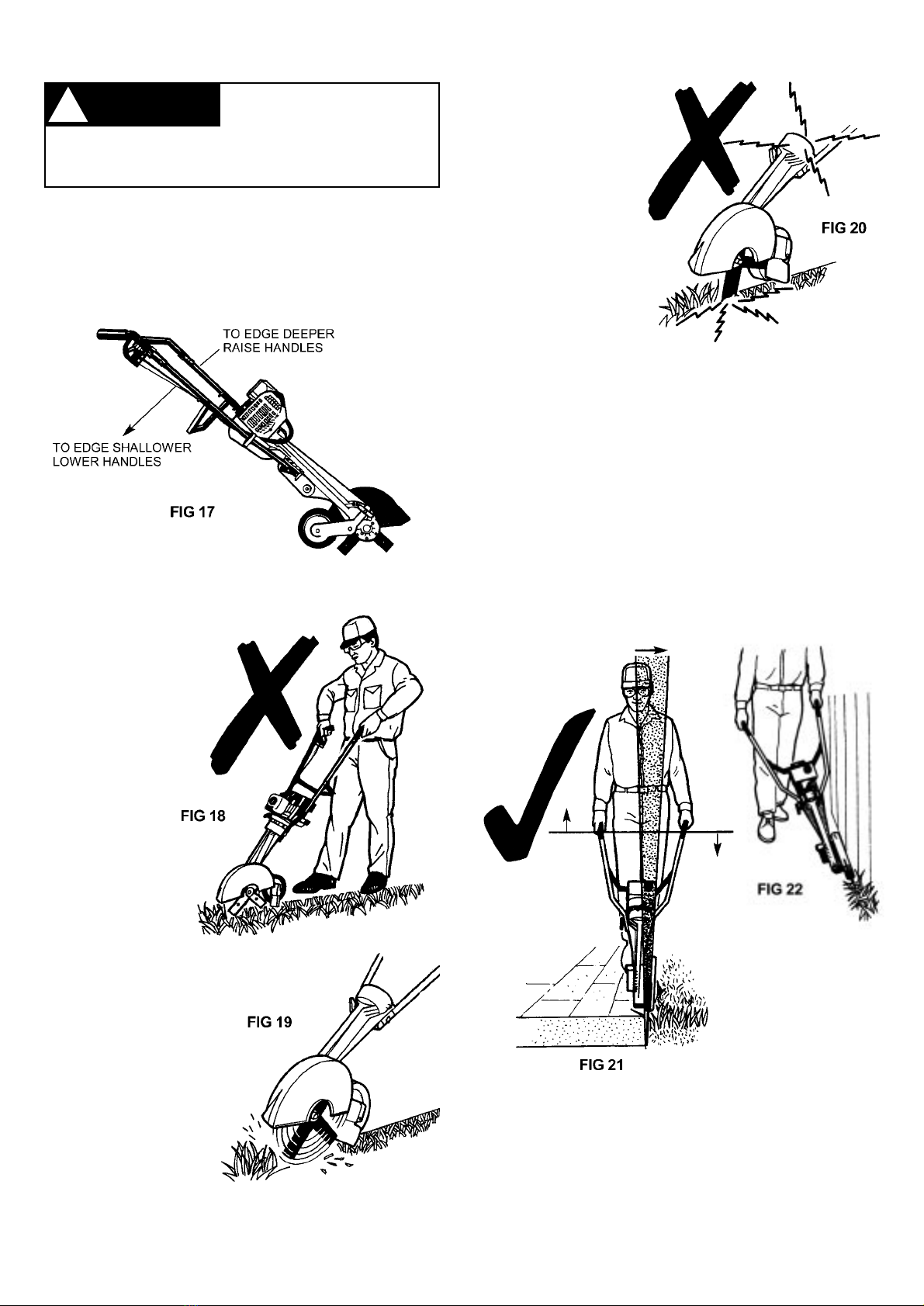

3 The throttle trigger which increases speed of

engine for automatic safety clutch to engage and

thus rotate blade.

4ON/STOP switch.

5Starter grip the grip of the pull starter which is the

device to start the engine.

6Handle nut for holding handles onto housing.

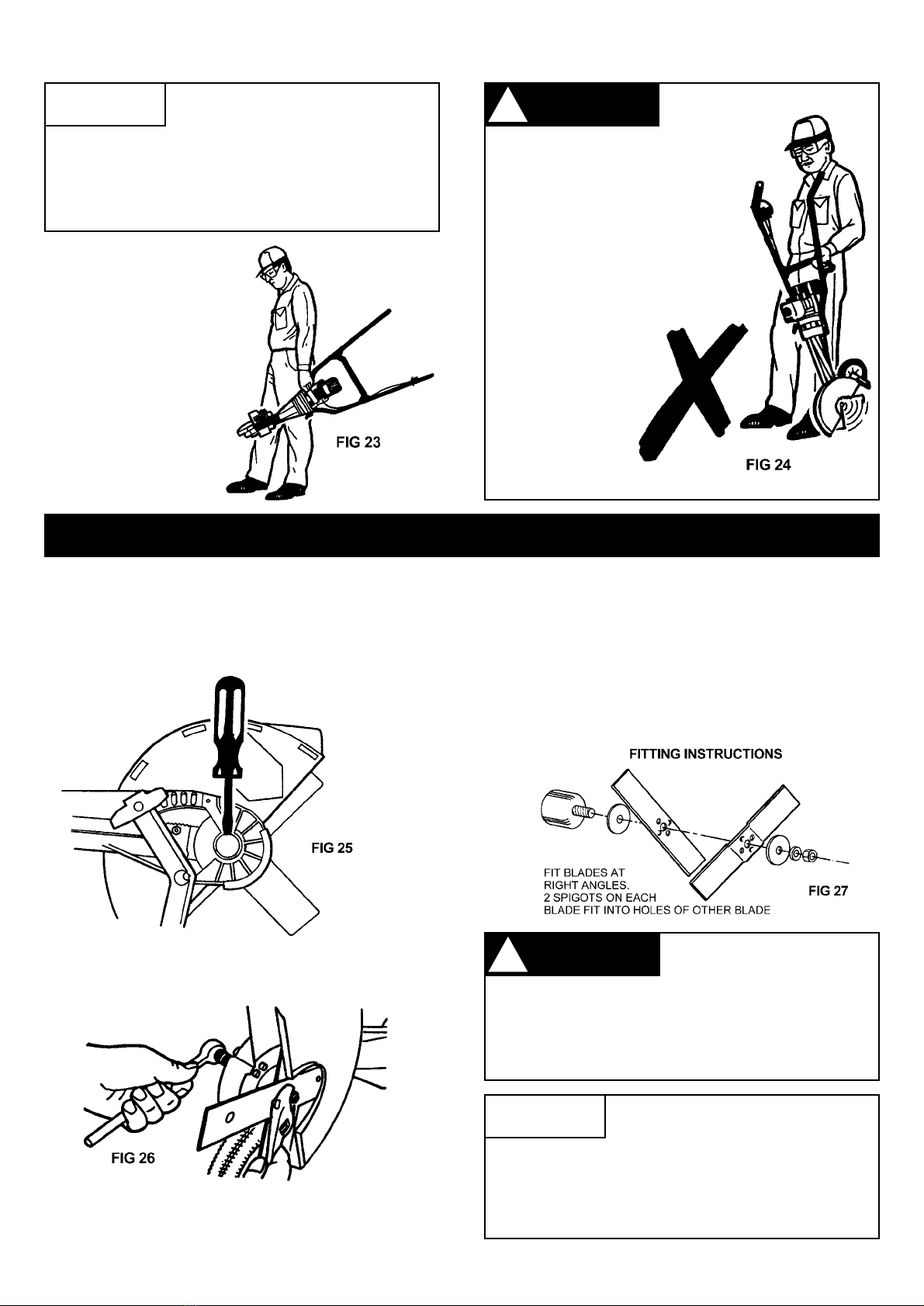

7Height adjustment for adjusting depth of cutting

blade.

8Blade cover reduces the risk of flying debris and

direct contact with the feet or hands.

9Sight guide for edging.

10 Cutter blades rotate when engine speed is

increased above idle.

11 Grass shield debris deflector reduces flyback of

stones and foreign material.

12 Wheel for moving and guiding edger.

13 Cross Brace, attaches downward on handle.

14 Left and right Handle Tubes.

15 Fuel cap, for sealing the fuel tank filler.

16 Fuel Tank.

17 Choke lever for cold engine starting.

18 Filter housing covers the air filter element.

19 Muffler reduces exhaust noises and diverts gases

away from operator.

20 Spark Plug terminal cap connects the spark plug

to the ignition wire.

21 Fuel pump primer under carburettor provides

additional fuel for starting.

22 Warning Label, on left handle.

23 Front Round Anti-Vibration Mounting.

24 RearRoundAnti-VibrationMounting(bothsides).

25 Twin Saddle AV Mounting (both sides).

26 Warning Label, on blade guard.

2

SAFETY WARNINGS

!

!WARNING !NOTE Advises you of information or

instructions vital to the

operation or maintenance of the equipment.