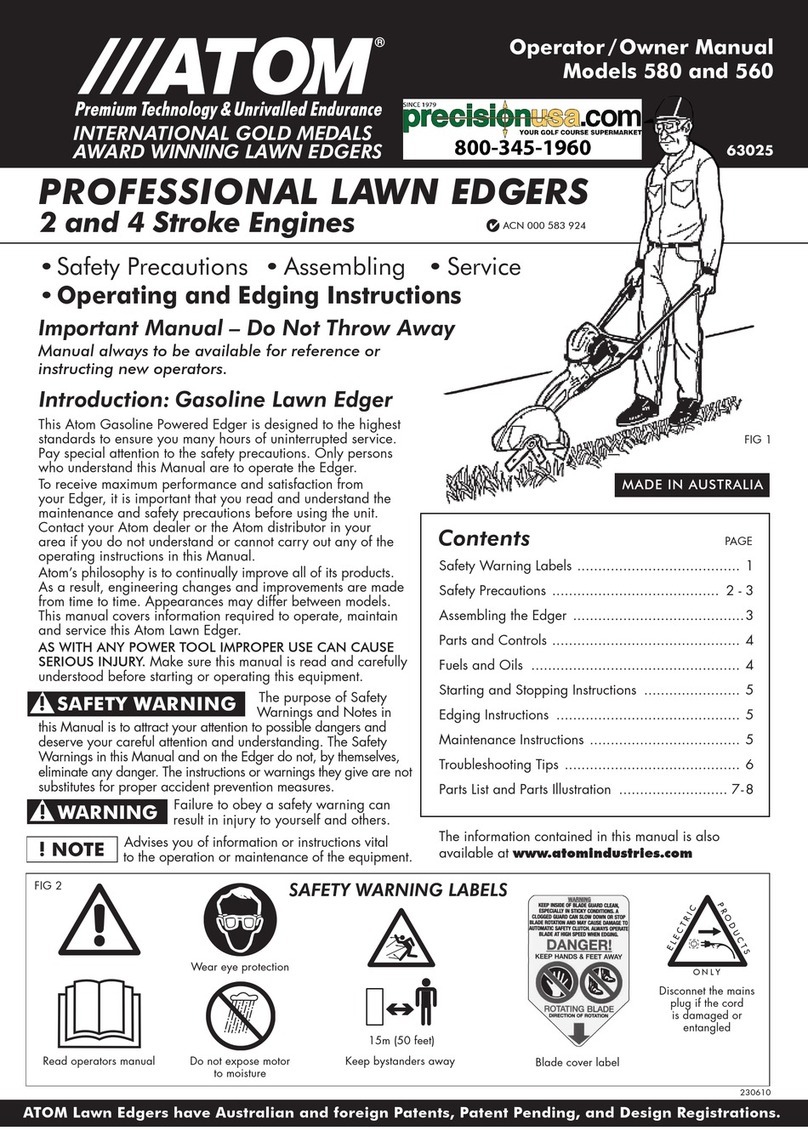

1,The

edger

isvery

easyandsimpletouseandmost

operatorscan

immediately

adapttoits

unique

flexible

USE,

For some peopleit may take a few edgingsto

become

accustomed

to its

operation.

2.Thoroughlyinspecttheareawheretheedgeristo

beusedand

remove

allstones,sticks,wiresandall

other

foreignobjects.

3. Adjust

bladedepth:

Try

second

hole

closestto

operator

(Fig,

12)

! NOTE I Failure

to adjustbladeto correct

- | edging height will cause

overheatingof motor and clutch due to blade

rotationstopping.

! NOTE I When cutting efficiently,

motor

- | willturnbladesathighspeed.

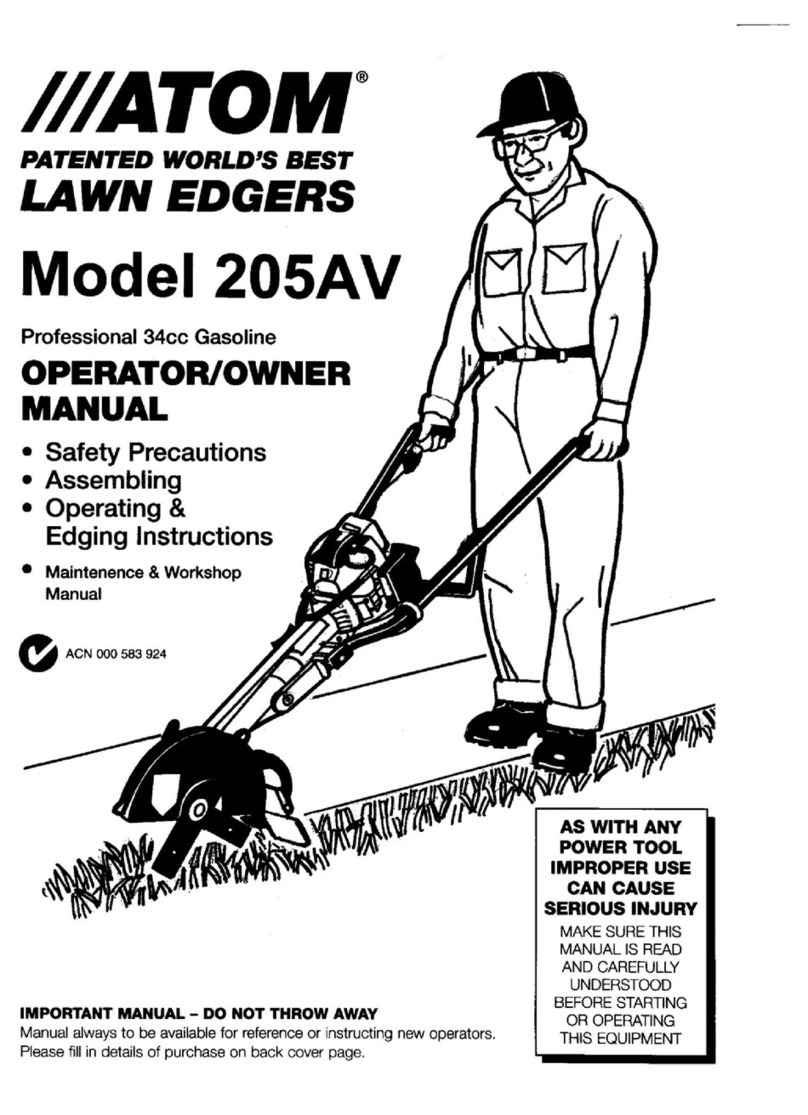

4. Withbotharms

fully

extendeddownwards

(see

illustration

on front

cover)

holdboth handle

grips

firmly,

The

bladeshould

just

clear

the

ground.

The

blade

is

now

set

high

soitcan

only

cutif

you

lift

your

arms

slightly

(100mm)(Fig

13).

7, As cuttingactionbegins,

movethe lawn

edger

forward

sothatthe bladecancut theedge

asyou

moveforuuard

(Fig.

15).

8.Continue

atamoderate

pace

untilyouare familiar

with

the

controlsandthe

handling

of

theAtom

Edger,

9. lf

blade

jams

orstopsinthe

ground(Fig.

16),lower

handlesor pull

backunitandrecommence.

Motor

shouldbeatfullsoeedunder

load.

x

FIG14

RAISE

TO

EOGETEPER

FIG13

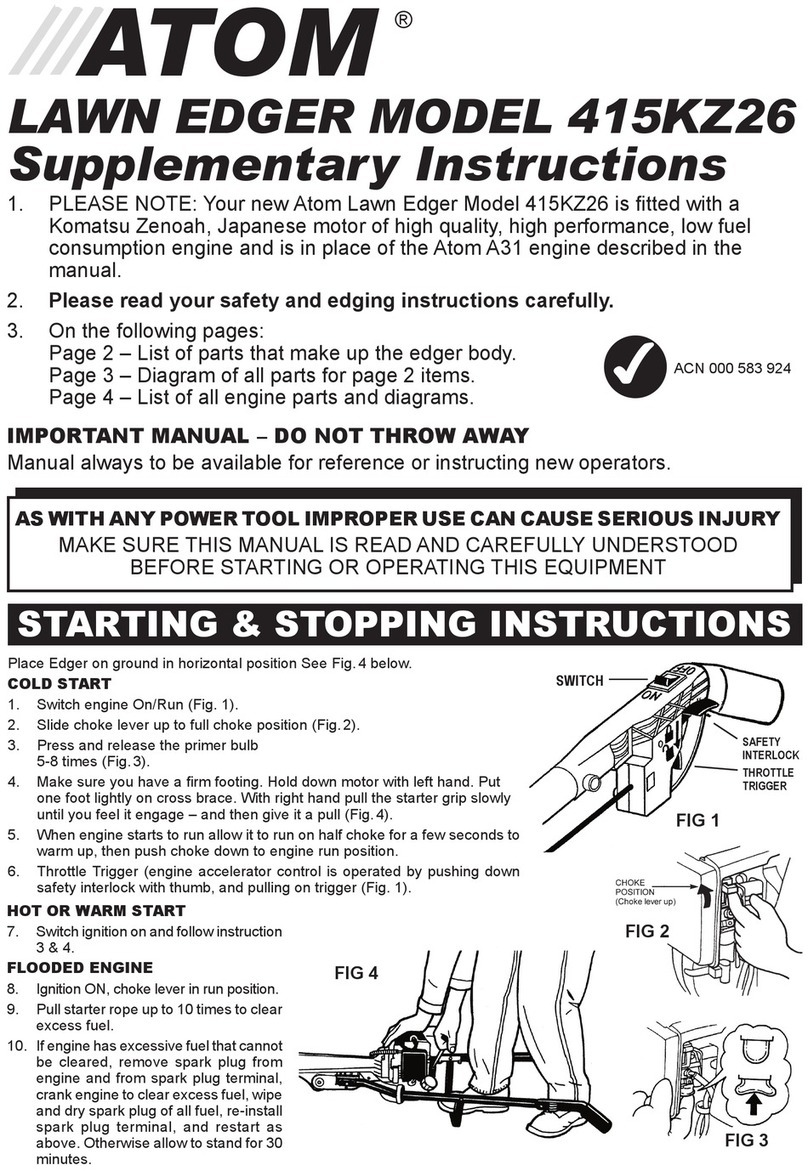

5.

Pull

throttletrigger

allowing

motor

tostart,You

can

practice

walking

fontrard

onanareaofyour

lawnor

garden

slightlylifting

your

arms,

holding

handlesfirmly

for

the

blade

tocutinto

the

ground.

This

will

giveyou

a"feel"

oftheoperating

technique.lfno.2 position

is

toohighthenset

atno.3

position.

6. Do not lift handlesby excessive

bendingof

elbows (Fig 14).Always keep arms straightas

shownon Front

Cover.

! NOTE I Allowingmotorto runexcessively

' l (1-2 minutes)

with bladesnot

rotatingwill

causeclutch

to burnout.

Only

operateunit

when

movingforward.

DONOT

operatewalkingbackwards,

as

youmay

trip,fafl

and

injure

yourself.

FIG15 FIG16