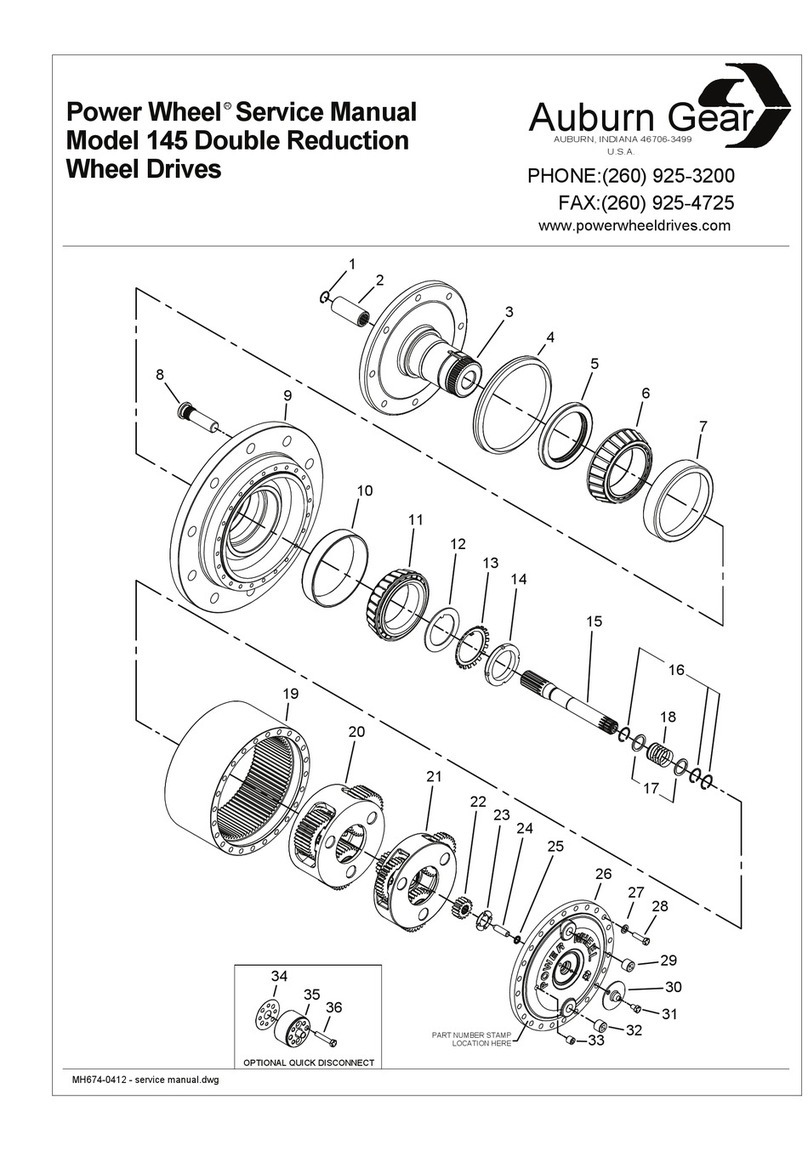

IDENTIFICATION

IMPORTANT: All Power Wheel units and kits are shipped with a nameplate that includes the Auburn Gear part number and order code as shown.

Example:

PowerWheel®

ORDER CODE: 6WB13156C

PART NO.: 6000236

SERIAL NO.: 143434

AUBURN, IN U.S.A.

2

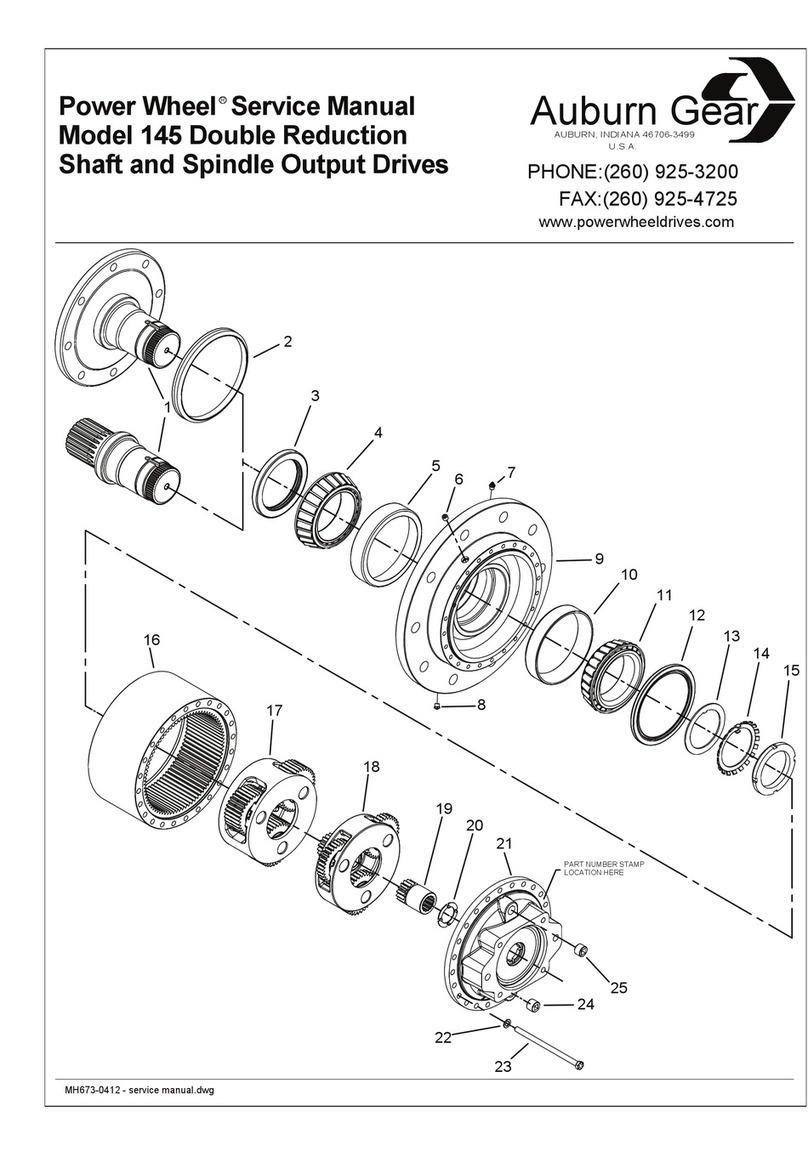

In addition to the nameplate, Power Wheel drives are stamped with an identification number which

appears on the cover or hub flange as shown.

Example: 6000236-A-4-9

When ordering parts, the information included on the nameplate or the stamped identification number is

necessary to accurately identify the drive and obtain the correct replacement parts. Once this information

has been obtained, contact Auburn Gear for the appropriate parts list.

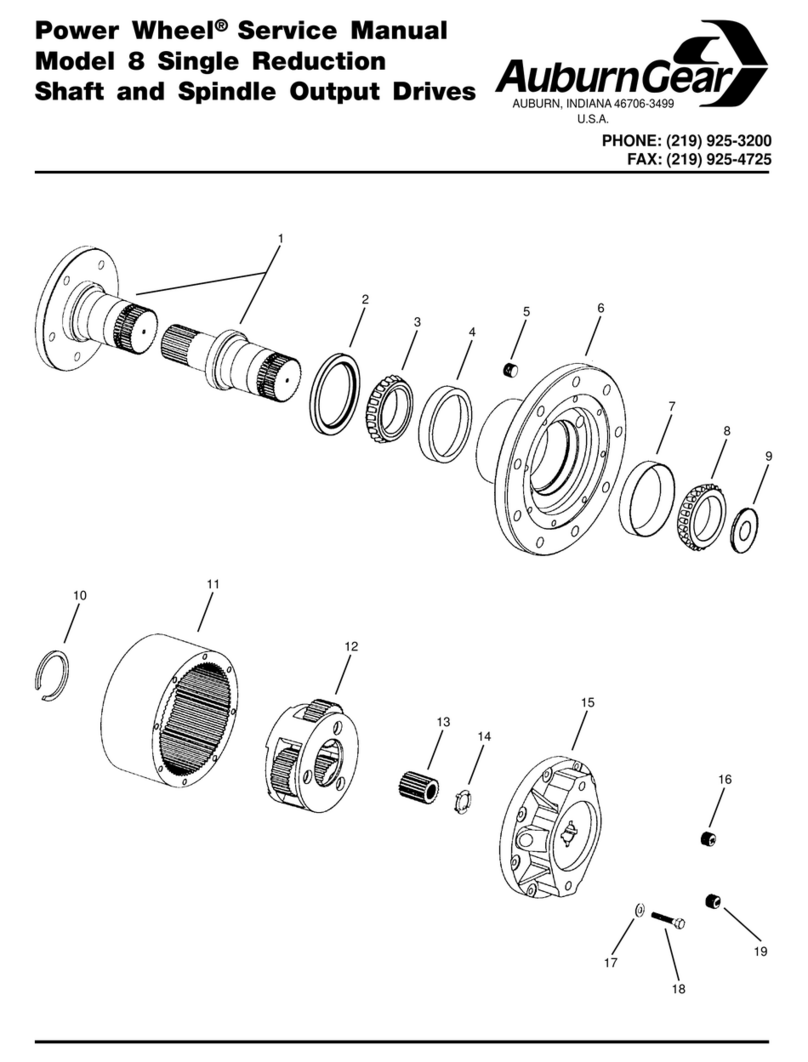

DISASSEMBLY OF POWER WHEEL

STEP 1

Ifbrakeportionof driveis tobe servicedremove motorfrom planetarydrive.Tempo-

rarilyinstalltwo1/2-13x1.25screwsintohydraulicmotormountingholesandtorque

to 50 lb. ft. (67 Nm). These must be used to hold spring back-up plate in position

whenparkingbrakeassemblyis removedfromthe drive.Ifthebrakeportionofdrive

does not require service go to step 5.

STEP 2

Remove the four T-50 Torx head screws (1) holding the parking brake assembly in

position. It may be necessary to lightly strike the piston assembly (2) with a rubber

mallet to loosen from spindle or cover.

STEP 3

Remove disc pack (3) from drive only if necessary. Be careful to maintain discs in

order.

STEP 4

If brake piston assembly (2) has been removed slide the coupling (4) and retaining

ring (5) from splines on input shaft (6). Remove sleeve bearing (7) if replacement is

required.

STEP 5

Position the assembly upright on face of spindle (9).

STEP 6

Remove the disengage cover (35) if necessary.

STEP 7

Remove twelve bolts (33), flat washers (32), and large cover (31) from the unit. The

thrust washer (28) and the disengage plunger (29) will usually remain attached to

the large cover (31) when it is removed. Remove thrust washer (28), disengage

plunger (29) and “O” ring (30) from the large cover (31).

STEP 8

Remove primary sun gear (27) from end of input shaft (6).

STEP 9

Remove primary carrier assembly (26).

STEP 10

Remove the secondary carrier assembly (25). It may be necessary to remove the

ring gear (23) first, if difficulty is encountered in removing the carrier.

STEP 11

Remove the input shaft (6) from spindle (9). Remove the retaining rings (20), wash-

ers (21), and spring (22) from input shaft (6) only if replacement is required.

STEP 12

If not previously removed (see step 10) remove ring gear (23) from hub (15). It may

be necessary to strike ring gear (23) with a rubber mallet to loosen from hub (15).

STEP 13

Removetheretainingring(19)frominfrontofthethrustwasher(18)andlift hub(15)

from spindle (9). If bearings are not a loose fit, it may be necessary to press spindle

(9) from hub (15). N

OTE

:Use a retaining ring expander tool to remove retaining ring

(19).

STEP 14

If included on unit, remove boot seal (10) from hub (15). Remove the oil seal (11)

and bearing cones (12 & 17) from hub (15). Inspect bearing cups (13 & 16) in

position and remove only if replacement is required.

ASSEMBLY OF POWER WHEEL

STEP 1

Press new bearing cups (13 & 16) in each side of the hub (15). It is recommended

that bearing cups (13 & 16) and cones (12 & 17) be replaced in sets.

STEP 2

Assemble bearing cone (12) into cup (13) at seal end of hub (15) and press a new

seal (11) into hub (15). Install boot seal (10) on hub (15) if unit is so equipped.

STEP 3

Positionspindle (9)uprightonbench.Lubricatelipsofseals(10 &11)andlowerhub

(15)onto spindle(9).Hub(15)shouldbecenteredasit islowered overspindle(9)to

prevent seal damage.

STEP 4

Assemble bearing cone (17) over spindle (9) and into bearing cup (16). If bearings

(12, 13, 16, & 17), hub (15) or spindle (9) is replaced, a new retaining ring (19) is

requiredforproperbearingsetting.Donotre-usesnapringafterithasbeeninstalled

andremovedfromunit. Selectthethickestretainingring(19)thatcanbeassembled

into the ring groove of the splined end of spindle (9) above bearing cone (17). Bear-

ing should have from .000 – .006 inches (.00 – .15mm) of end play when proper

retaining ring (19) is installed.

STEP 5

Assemble a washer (21), spring (22), a second washer (21), and a retaining ring

(20) in the middle groove of input shaft (6).Assemble a second retaining ring (20) in

grooveoppositepilotendofinputshaft(6).Someshaftshaveashoulderandrequire

only one retaining ring (20).

STEP 6

Assemble the splined end of the input shaft (6) down into spindle (9).

STEP 7

Assemble secondary carrier assembly (25) to spindle (9) at splines.

STEP 8

Clean mating surfaces and apply a bead of silicone sealant to face of hub (15) that

mates with ring gear (23). (See instructions on sealant package). Position ring gear

(23) on hub (15) being careful to align bolt holes.

STEP 9

Assemble the primary carrier assembly (26) into the ring gear (23). It will be neces-

sary to rotate carrier to align secondary sun gear {part of primary carrier assembly

(26)} with planet gear teeth in secondary carrier assembly (25). Assemble primary

sun gear (27) over input shaft (6). Rotate primary sun gear (27) to align input shaft

(6) to gear splines and gear teeth in primary carrier assembly (26).

STEP 10

Lubricate“O”ring (30)andassemble ingrooveinside coverhole,push plunger(29)

into cover with pointed end facing inside of unit.

STEP 11

Assemble the thrust washer (28) with tangs engaged with cover (31). N

OTE

:Asmall

amount of grease applied to the back side of thrust washer (28) will hold washer in

place.Applyabeadofsiliconesealanttoend faceof ringgear (23).Assemblecover

(31)aligningholesofcoverandringgear.Assemblethetwelveflatwashers(32)and

3/8 – 16x5 1/2 inch hex head bolts (33). Torque bolts to 45 – 50 lb. ft. (61 - 67 Nm).

STEP 12

Assemblethedisengage cover (35)withdimpled center protrudingoutif wheel isto

beusedtodrivethevehicle.Assembleandtorquethetwo5/16–18bolts(36).Torque

bolts to 10 – 20 lb. ft. (13 – 27 Nm).