Audi-Cord Corporation TDS Series User manual

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Table

of

Contents

TWIN

DECK

"ms"

SERIES

REPRODUCERS

1,0

GENERAL

DESCRIPTION

1.1

Un-Packing

1.2

Models

and

Accessories

2,0

SPECIFICATIONS

3,0

OPERATION

3.1

Getting

the

Most

From

the

Cartridge

System

3.2

Selecting

and

Using

the

Customer

Operating

3.3

Constructing

Output

Pads

3.4

Controls

and

Indicators

3.5

Audio

Connections

3.6

Remote

Control

Connections

3.7

Operator

Periodic

Maintenance

4,0

CIRCUIT

DESCRIPTIONS

Options

4.1

Power

Supply

and

Power

Switching

Circuits

Card

4.2

Twin

Deck

Logic

Circuits

Card

4.3

Program

Amplifier(s)

and

Cue

Circuits

Card

4.4

Output

Circuits

Card

5,0

TRANSPORT

DESCRIPTIONS

5.1

The

Tape

Drive

Systems

5.2

Head

Mountings

and

Tape

Guides

5.3

Cartridge

Sensors

5.4

Cartridge

Guides

and

Hold

Downs

6,0

TRANSPORT

DIAGNOSIS

AND

MAINTENANCE

6.1

Transport

Failure

or

Cartridge

and

Tape

Failure?

6.2

Adjustment

of

Cross-Shaft

Mechanism

6.3

Solenoid

Adjustment

6.4

Motor

Adjustment,

Top

Deck

6.5

Lower

Deck

Stop

Adjustment

6.6

Tape

Guide

and

Head

Height

Adjustment

6.7

Head

Penetration,

Angle

and

Cartridge

Tape

Wrap

7,0

ELECTRICAL

MAINTENANCE

7.1

Adjustment

of

Lower

Deck

Azimuth

and

Pha

se

7.2

Head

Azimuth

and

Phase,

Routine

7.3

Frequency

Response

and

Equalization

7.4

Program

Output

Level(s)

7.5

Cue

Detectors

Gain

(a)

PAGE

1

1

2

3

6

6

7

9

10

11

12

12

14

14

14

16

18

19

19

19

19

20

21

21

22

23

23

23

24

25

26

26

26

28

28

29

www.SteamPoweredRadio.Com

8,0

TROUBLESHOOTING

8.1

Mechanical

Failures

in

the

Tape

Drive

System

8.2

Logic

and

Control

Circuits

8.3

Program

Amplifier

and

Cue

Circuits

8.4

Parts

Identification

and

Ordering

Parts

8.5

Symptoms

and

Possible

Cause

Chart

9,0

CIRCUIT

CARD

SCHEMATICS

AND

PICTORIALS

10,0

INTERCONNECTIONS

(tvOTHER

BOARD)

SCHEMATIC

11,0

WARRANTY

(b)

30

30

31

32

32

33

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

1.0

I

I

I

I

I

I

I

I

I

1.1

I

I

I

I

I

I

AUDI-CORD

CORPORATION

''TDS"

SERIES

TWIN

DECK

REPRODUCERS

GENERAL

DESCRIPTION

The

Audi-Cord

Corporation

TDS

Series

Twin

Deck

Reproducers

represent

a

practical

design

in

multi-deck

tape

cartridge

reproducers

that

are

cost-value

engineered

for

long

and

reliable

service.

We

hope

you

will

be

pleased

in

your

selection

of

these

machines

and

the

service

they

will

provide.

Please

take

a

few

minutes

to

read

and

understand

this

instruction

book

before

placing

the

unit

in

service.

To

do

so

will

undoubtedly

provide

y

ou

with

important

information

from

which

to

realize

the

most

from

your

investment.

The

TDS

Series

contains

the

latest

in

solid

state

components

and

modern

hardware,

designed

into

a

readily

accessable

unit

with

a

minimum

of

discreet

wiring.

The

only

moving

parts

are

the

solenoid

and

the

associated

tape

engaging

mechanism.

The

operator

controls

are

on

the

front

panel

along

with

the

important

annuciator

light

s

arranged

for

ease

of

operation

and

understanding.

The

TDS

Series

is

designed

in

harmony

with

the

1976

NAB

Cartridge

Standards

and

it's

intent;

however

certain

level

and

response

parameter

s

are

s

upplied

to

be

more

consistent

with

the

needs

of

the

U.S.

domestic

market

use.

Th

e s e

parameters

are

readily

alt

e

red

by

the

user

to

the

197

6

NAB

Standard

when

desired,

following

the

instructions

i n

Section

7.0,

Electrical

Maintenance

and

Section

3.3,

Constructing

Output

Pads.

Un-Packing

Please

un-pack

carefully

and

retain

the

shipping

materials

until

a

full

inspection

is

completed.

Before

plugging

the

"TDS"

Series

into

the

proper

power

source

examine

the

equipment

for

shipping

damage

both

exterior

and

interior.

Audi-Cord

Corporation

makes

every

possible

attempt

to

design

the

equipment

and

the

packing

such

that

they

will

arrive

in

safe

condition;

however,

rough

handling

by

the

carrier

can

not

always

be

avoided.

1.

www.SteamPoweredRadio.Com

Examine

each

circuit

card

to

insure

it

has

not

worked

loose

from

its

socket

and

inspect

heavy

members

such

as

the

transformers

to

insure

they

have

not

been

broken

loose

or

shifted

on

their

mountings.

If

damage

has

occurred,

please

notify

Audi-Cord

first

for

advise

on

claims

so

that

we

may

avoid

un-necessary

delay

to

the

repair

and

your

use

of

the

equipment.

1.2

MODELS

AND

ACCESSORIES

The

TDS

Series

Twin

Deck

Reproducer

is

available

in

two

standard

models.

MODEL

TDS-1

-

Monophonic

with

3

NAB

Cue

Tones

MODEL

TDS-6

-

Stereophonic

with

3

NAB

Cue

Tones

other

models

are

available

only

on

special

quantity

orders

and

factory

quotation.

An

accessory

rack

mounting

shelf,

part

no.

502-0046

is

available

for

mounting

up

to

two

(2)

units

side

by

side

in

a

rack

conforming

to

RMA

standards.

2.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

2.0

SPECIFICATIONS:

"ms"

SERIES

REPRODUCERS

Rated

Audio

Output

Amplifier

Overload

Capability

Minimum

Input

Level

Rated

Output

Impedance

Amplifier

Output

Impedance

Amplifier

Distortion

Hum

and

Noise

Signal

to

Noise

(Typi~al.

Tape)

Crosstalk,

Cue

to

Program

Crosstalk,

Program

To

Program

Start

Time

Stop

Time

Equalization

Equalization

Adjustment

Frequency

Response

+8dBm

max.

,

factory

pad

installed

for

O

dBm

ou

t

pu

t

+18

dBm

min.,

+20

dBm

c l

ipping

Loss

Pad

Out

+8

dBm

min.

fr

om

160

nWb/m

fluxivity

,

Pad

Out

600

ohms

or

150

ohms

Balanced

Selectable

*

300

ohms

on

600

ohms

tap

*90

ohms

on

150

ohms

tap

0.5%

max

total

harmonic@+

18

dBm

-52

dB

re

160

nWb/m @

lKhz,

Mono

-48

dB

re

160

nWb/m @

lkHz,

Stereo

-47

dB

re

160

nWb/m @

lkHz

50

dB

or

better

@ 1 kHz

50

dB

or

better

@ 1 kHz

0.12

Sec.

Max.

@

Min.

Solenoid

Damping

0.08

Sec.

Max.

@

Min.

Solenoid

Damping

*Per

NAB

Cartridge

Standard,

1964,

Adjustable,

due

to

customer

demand

Both

high

and

low

frequencies

Adjustable

+2 dB

to

NAB

Standard

Tape

specificat

i

ons

,

typically

limite

d

by

head

contour

effects@

low

Frequencies

Voe.-o

not

6uLe.y

meet

the

19

76

NAB S

tandCVtd..6

3 .

www.SteamPoweredRadio.Com

Phase

Stability

Cue

Tones

Cue

Inhibit

Time

SEC/TER

Cue

Switching

Cue

Switching

Loads

Logging

Output

Isolation

Cue

Sensor

Bandwidth

Cue

Sensor

Gain

Tape

Speed

Timing

Accuracy

Effective

Speed

Accuracy

Flutter

4.

~90

de

gr

ee

s,

Long

Term

@

12

kHz

TJtaMpold

,i,.f.,

fong-teAm ph.Me

.6tabf

e

6otr..

.6efec.ted

c.M.;tJu,dg

e. undeJt

c.ontltoUed

meMUJtemen;t/2.

It

,i,.f.,

applteuated

th.at

phMe

cUnneAentiaf

oveA

a

g1toup

06

cM.;tJu,dge

.6

and

long

teAm

Me

,i,.f.,

di66,i.,c.uU

to

ac.h.uve

unfu.6

.6:tlungent

maint

enanc.e and

opeAatoJt

tec.h.Mquu

Me

applied.

Th.,i,.f.,

.6peu6ication,

th.eAe6otr..e,

1t

e.-

p1tuent.6 a

but

cM

e

intent

and

c.annot be

guManteed

in

th.e

MeA

'.6

appuc.ation

undVi. plte.M.

nt

typical

o

peAatio

M •

lkHz

Primary,

150

Hz

Secondary

Cue

and

8 kHz

Tertiary,

Standard

1.75

sec+

.25

sec.

Electronic

Timed

Sinking

(Open

cofiec.toJt)

logic

100

ma.

max.,+40

VDC

open

circuit

max.

40

dB

min.,

from

l0K

ohm

source

+5

%

min@

6 dB

points

10

dB

minimum

Reserve@

NAB

Std.

Level

7.5

IPS,

Hysteresis

Synchronous

Direct

Drive

.2%,

250

Sec.

Tape

Method

.2%

NAB

Method

0.15%

weighted

peak,

Maximum

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Remote

Control

(a.1.1_

inpUM

aJte.

g1r.ound

-6igna.1.1_e,d)

Cartridge

Capability

Max.

Temp.

Rise

Recommended

Max.

Ambient

Power

Requirements

Dimensions

Weight

5.

15

Pins,

permanently

wired

for:

Start

Stop

Run Lamp

Ready

Lamp

Secondary

Cut

Out

Tertiary

Cue

Out

Gnd

(ChaMi-6)

+24

DC

Logging

Cue

Output

NAB

AA

and

BB

sizes

20

C.

Max.

above

25

C

ambient

40

C

max.

117

volts,

60

Hz,

60

VA

max.

(117

vo-lto,

50

Hz,

on

-6pe.ual

01r.de.1r.>

8!:;"W

x

7!:;"H

x

13~"L

26

lbs.

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

3,0

OPERATION

3.1

GETTING

THE

MOST

FROM

THE

CARTRIDGE

SYSTEM

It

is

Audi-Cord's

desire

that

every

owner

of

the

"TDS"

Series

Reproducer

obtain

long

and

satisfactory

service

from

the

equipment;

however,

since

the

"TDS"

Series

is

manufactured

to

accommodate

a

wide

variety

of

cartridges

from

several

manufacturers',

it

is

often

true

that

optimum

performance

is

the

result

of

the

users

knowledge

of

the

differences

in

these

cartridges

and

their

best

applications.

If

these

factors

are

well

known,

the

mechanical

fit

of

the

machine

and

the

cartridge

can

often

be

optimized

by

the

skilled

technician

for

best

performance.

Characteristics

which

most

often

influence

performance

of

a

given

cartridge

in

any

machine

are

as

follows:

1.

The

mechanical

fit

of

the

cartridge

to

the

heads

and

the

keyhole

opening.

2.

The

pressure

pad

design

adequacy

and

fit

to

the

heads

as

well

as

interference

to

the

tape

guides.

In

erase/record

applications

for

instance

only

a

few

types

will

adequately

wrap

these

off

center

head

designs.

3.

The

friction

loss

of

the

cartridge

and

tape

and

its'

pulling

tension.

Unlimited

tension

cannot

be

handled

by

the

transport

since

the

capstan

and

roller

surface

engagement

area

is

limited

in

the

inherent

design.

Tension

typically

increases

significantly

with

longer

time

loads

and

in

wear

life.

4.

Contamination

of

the

head

surfaces

if

poor

tape

and

lubricant

is

encountered.

5.

The

internal

quality

contro

l

and

maintenance

routines.

The

above

ch

aracteri

stics

are

all

important

if

failure

of

the

system

is

to

be

avoided.

It

is

unfortunately

true

that

all

cartridges

are

not

the

same

in

design

and,

it

is

virtually

impossible

to

produce

a

cartridge

transport

that

performs

perfec

tly

with

all

the

types;

therefore,

the

user

must

se

lect

the

cartridge

and

tape

best

suited

to

his

needs

and

then

make

such

minor

adjustments

to

the

transport

as

necessary

to

obtain

optimum

performance.

6.

www.SteamPoweredRadio.Com

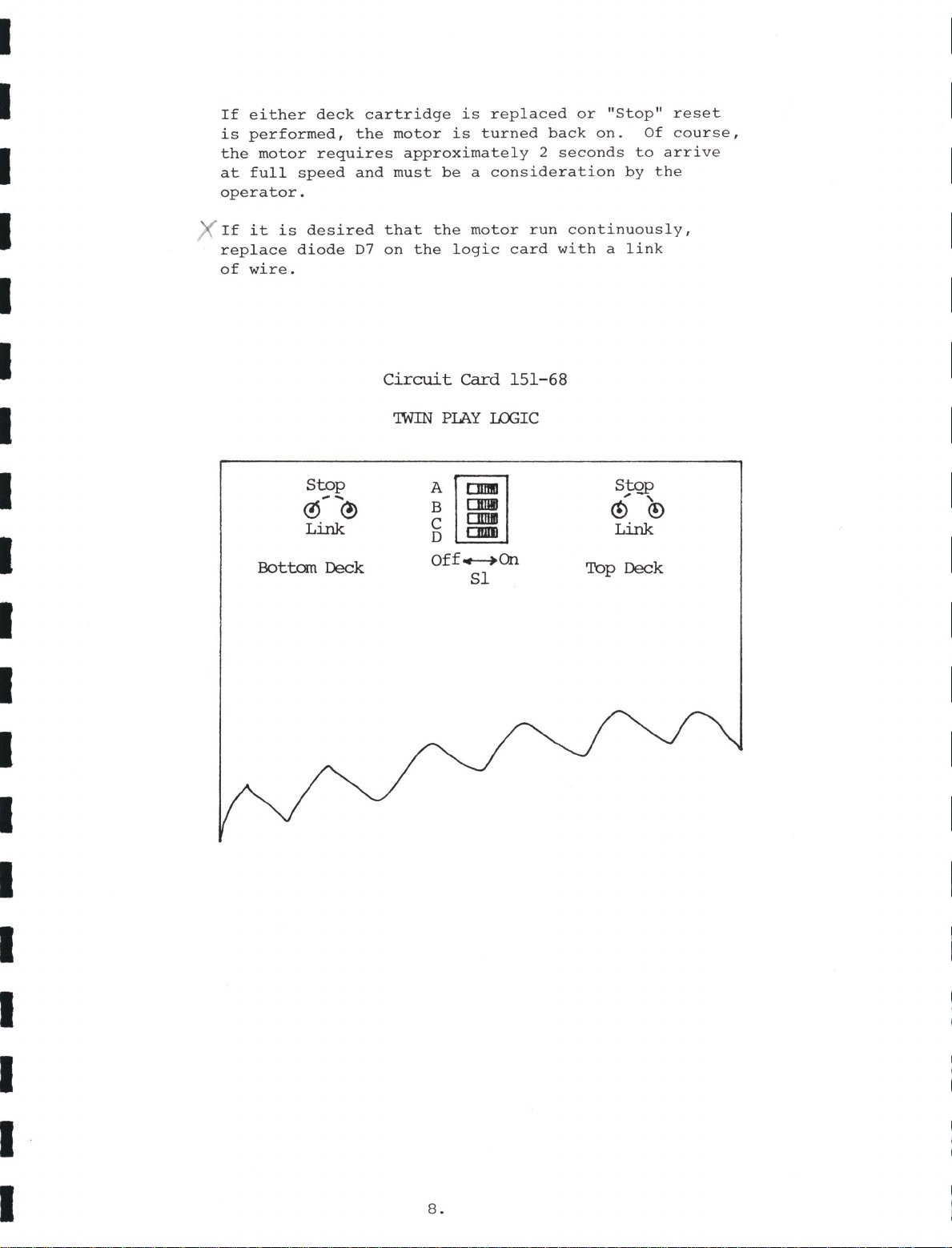

3.2

Our

Service

Department

will

provide

assistance

when

needed

and

excellent

general

information

is

to

be

found

in

our

Users'

manual

and

the

occasional

updates

that

have

been

issued.

SELECTING

AND

USING

THE

CUSTOMER

OPERATING OPTIONS

The

"TDS"

Series

reproducers

are

equipped

with

a

Replay

Reminder

and

Lockout

System

for

each

deck

and

an

automatic

Motor

Shut

Down

feature

when

both

decks

have

played.

The

customer

selects

how

he

uses

these

features

to

suit

the

needs

of

his

own

operation.

REPLAY

REMINDER

and

LOCKOUT

SYSTEMS-

This

feature

is

valuable

in

line

operations

to

prevent

double

airing

of

carts

that

have

been

previously

played.

The

feature

is

selected

by

switch

Sl,

located

on

the

top

of

the

Twin

Play

Control

Logic

Card

151-68.

Select

this

feature

to

turn

on

the

"Played"

lamp

and

remove

the

"Ready"

status

and

it's

lamp

by

setting

Sections

A

and

B

of

switch

Sl

to

the

"on"

position

for

the

lower

deck

and

sections

C

and

D

of

switch

Sl

to

the

"On"

position

for

the

upper

deck.

If

it

is

desired

to

turn

on

the

"Played"

lamp

only

and

not

remove

the

"Ready"

state,

turn

on

section

A

of

switch

Sl

for

the

lower

deck

and

section

C

for

the

upper

deck,

leaving

sections

Band

Din

the

"off"

position.

The

TDS

reproducer

is

factory

wired

to

allow

reset

of

the

Replay

Reminder

by

either

removing

the

appropriate

cartridge

or

by

pushing

the

"Stop"

pushbutton

of

the

associated

deck.

If

it

is

desired

to

exclude

the

"reset"

by

STOP

pushbutton

feature,

clip

the

buss

link

at

the

top

of

the

card

for

either

or

both

decks.

This

link

is

located

on

the

R.H.

side

(parts

facing)

for

the

top

deck

and

on

the

L.H.

side

for

the

bottom

deck.

MOTOR

SHUTDOWN

FEATURE-

This

feature

is

electrically

designed

to

follow

the

use

of

the

"READY"

status

of

either

deck

with

the

Replay

Lock-out.

If

both

decks

have

been

played

and

therefore

may

be

idle

for

some

period,

the

motor

is

turned

off

to

conserve

energy

and

heat

in

the

machine.

7.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

If

either

deck

cartridge

is

replaced

or

"Stop"

reset

is

performed,

the

motor

is

turned

back

on.

Of

course,

the

motor

requires

approximately

2

seconds

to

arrive

at

full

speed

and

must

be

a

consideration

by

the

operator.

If

it

is

desired

that

the

motor

run

continuously,

replace

diode

D7

on

the

logic

card

with

a

link

of

wire.

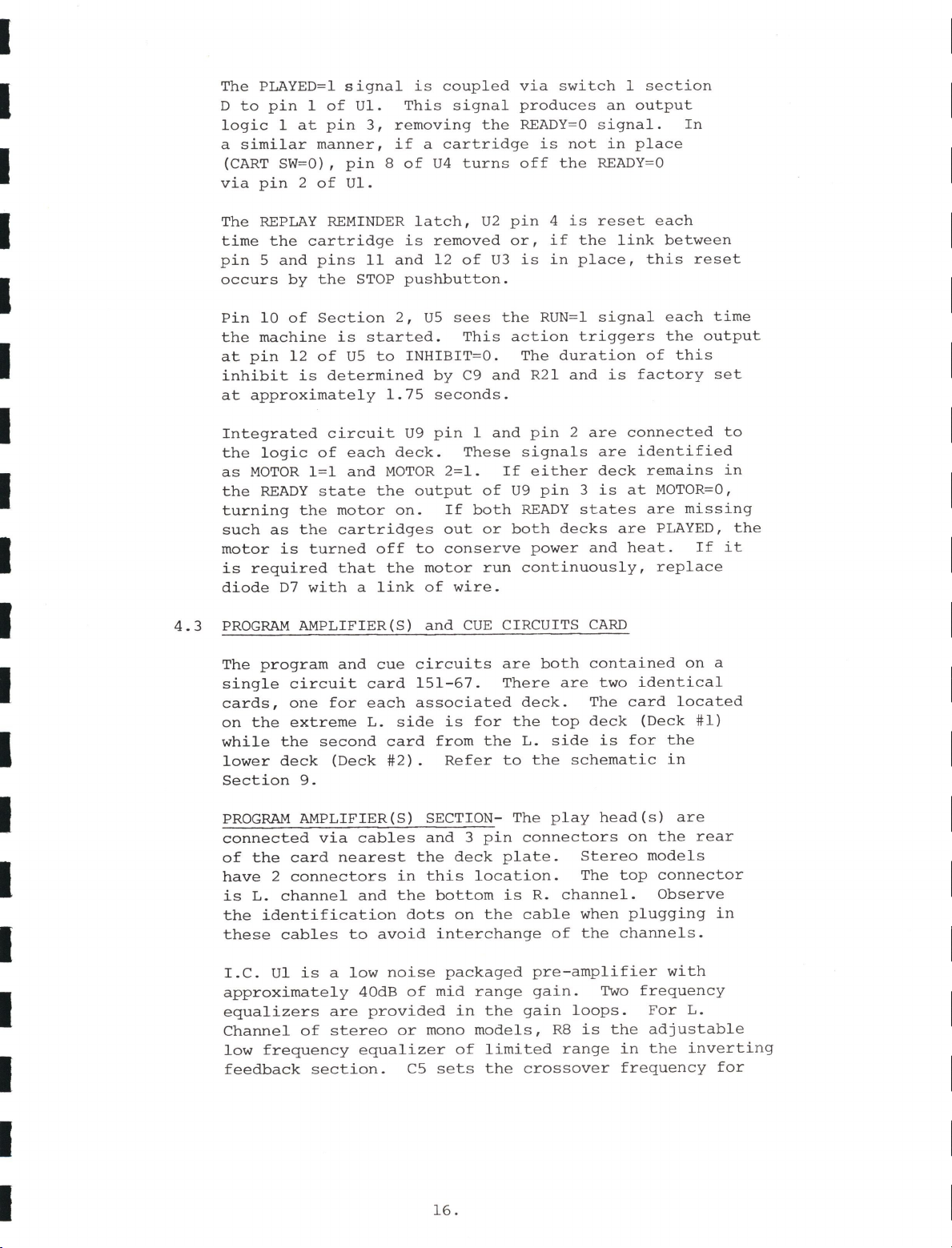

Stop

~--<?)

Link

Bottom Deck

Circuit

card

151-68

'IWIN

PIAY

ux;rc

B

CHilll

Al

C

DIDII

D

ODDI

Off..-+On

Sl

8.

StQP

, '

@ ©

Link

Top Deck

www.SteamPoweredRadio.Com

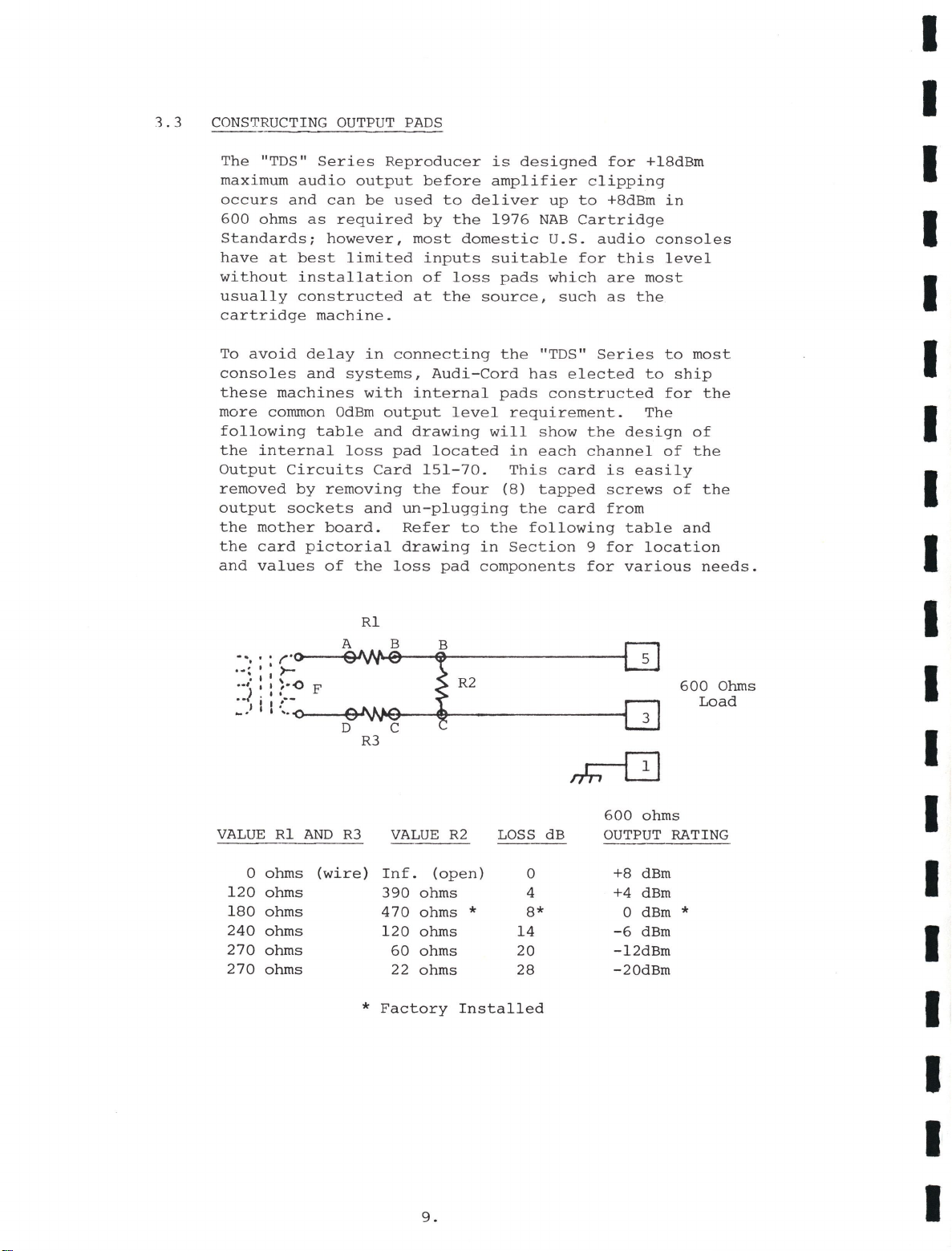

1.3

CONSTRUCTING

OUTPUT

PADS

The

"TDS"

Series

Reproducer

is

designed

for

+18dBm

maximum

audio

output

before

amplifier

clipping

occurs

and

can

be

used

to

deliver

up

to

+8dBm

in

600

ohms

as

required

by

the

1976

NAB

Cartridge

Standards;

however,

most

domestic

U.S.

audio

consoles

have

at

best

limited

inputs

suitable

for

this

level

without

installation

of

loss

pads

which

are

most

usually

constructed

at

the

source,

such

as

the

cartridge

machine.

To

avoid

delay

in

connecting

the

"TDS"

Series

to

most

consoles

and

systems,

Audi-Cord

has

elected

to

ship

these

machines

with

internal

pads

constructed

for

the

more

common

OdBm

output

level

requirement.

The

following

table

and

drawing

will

show

the

design

of

the

internal

loss

pad

located

in

each

channel

of

the

Output

Circuits

Card

151-70.

This

card

is

easily

removed

by

removing

the

four

(8)

tapped

screws

of

the

output

sockets

and

un-plugging

the

card

from

the

mother

board.

Refer

to

the

following

table

and

the

card

pictorial

drawing

in

Section

9

for

location

and

values

of

the

loss

pad

components

for

various

needs.

Rl

VALUE

Rl

AND

R3

VALUE

R2

LOSS dB

0

ohms

(wire)

Inf.

(open)

0

120

ohms

390

ohms

4

180

ohms

470

ohms*

8*

240

ohms

120

ohms

14

270

ohms

60

ohms

20

270

ohms

22

ohms

28

*

Factory

Installed

9.

600

Ohms

Load

600

ohms

OUTPUT

RATING

+8

dBm

+4

dBm

0

dBm*

-6

dBm

-12dBm

-20dBm

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

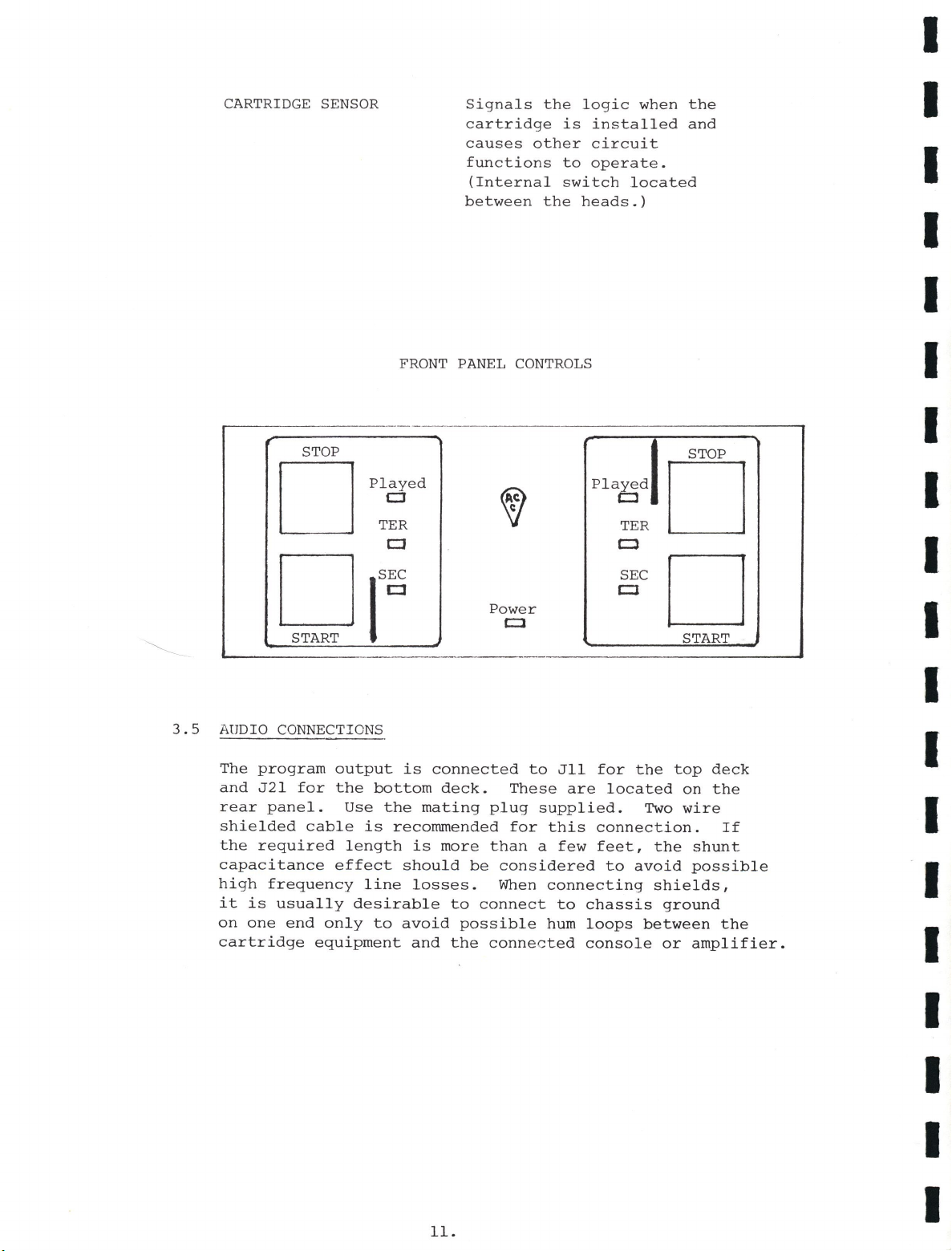

3.4

CONTROLS

AND

INDICATORS

The

operator

controls

and

indicators

for

the

TDS

Series

reproducers

consist

of

two

sets,

conveniently

grouped

for

operator

identification

of

the

deck

with

which

they

are

associated.

Each

group

contains

an

arrow

symbol

painting

to

the

deck

which

they

operate

with.

The

.

function

of

each

control

or

indicator

without

reference

to

the

deck

used

are

as

follows:

POWER

LIGHT

READY

LIGHT

STOP

PUSHBUTTON

Indicates

that

the

machine

is

on

and

that

the

+24

DC

power

is

present.

Indicates

that

a

cartridge

has

been

properly

installed

and

is

ready

to

play.

(this

lamp

is

part

of

the

STOP

pushbutton.)

Stops

the

transport

and/or

resets

the

REPLAY

reminder

when

this

option

is

selected.

(Remember

that

manual

stop

of

a

cartridge

leaves

it

in

an

un-cued

state

and,

the

cart

should

be

advanced

to

cue

befor

E:_

removalJ

RUN

LIGHT

Indicates

that

the

transport

is

in

the

run

mode

and

playing.

START

PUSHBUTTON

Places

the

transport

in

the

run

mode.

PLAYED

LITE

Indicates

that

the

cartridge

in

place

has

received

the

Primary

Cue

Tone

and

has

been

played.

TER

LITE

SEC

LITE

Indicates

when

the

TER

cue

tone

is

being

received.

Indicates

when

the

SEC

cue

tone

is

being

received.

10.

www.SteamPoweredRadio.Com

CARTRIDGE SENSOR

Signals

the

logic

when

the

cartridge

is

installed

and

causes

other

circuit

functions

to

operate.

(Internal

switch

located

between

the

heads.)

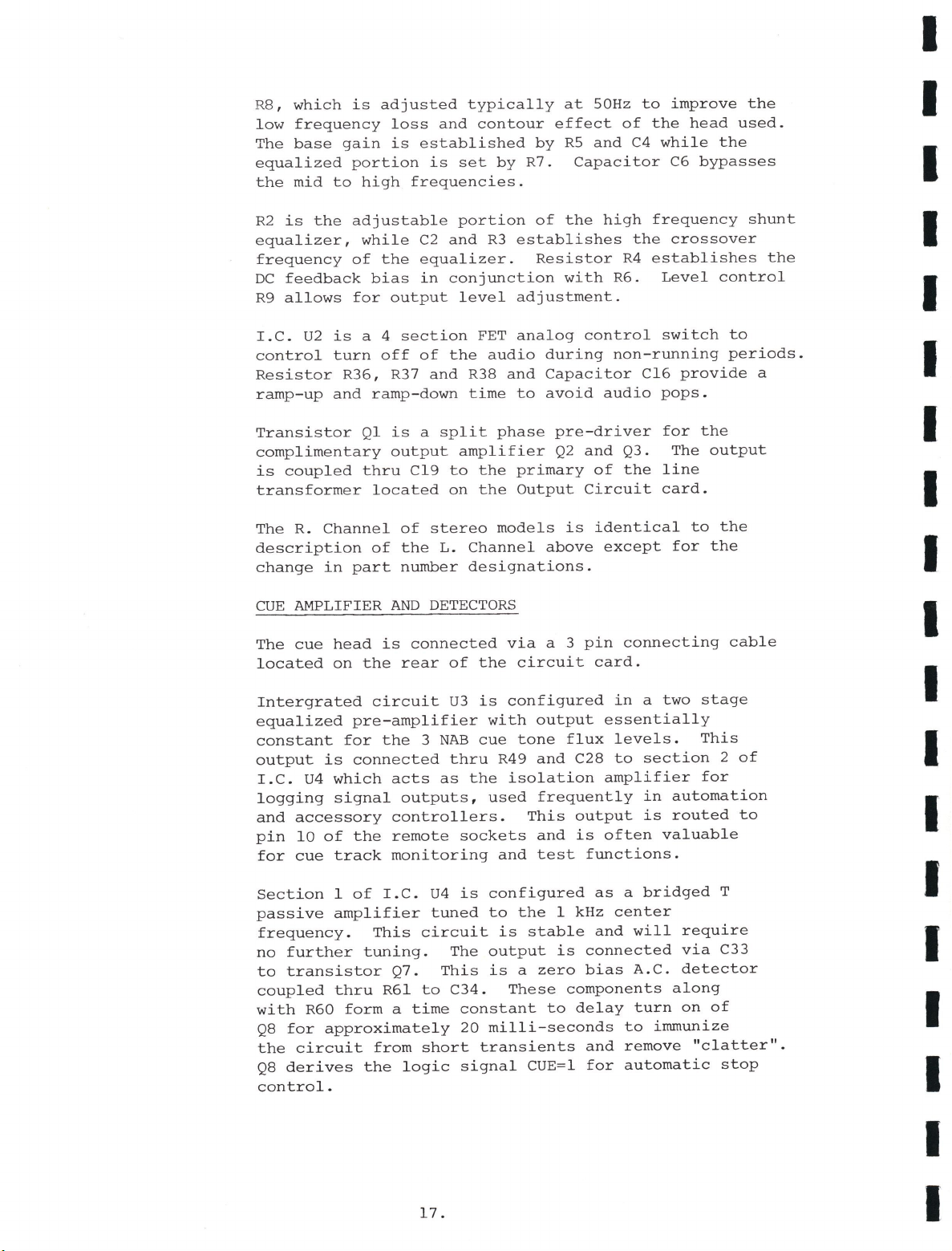

FRONT

PANEL

CONTROLS

STOP STOP

□

Played

fl

CJ

TER

Played

□

c:J

TER

□

Cl

□

SEC

START

ICJ

Power

CJ

SEC

□

CJ

START

3.5

AUDIO

CONNECTIONS

The

program

output

is

connected

to

Jll

for

the

top

deck

and

J21

for

the

bottom

deck.

These

are

located

on

the

rear

panel.

Use

the

mating

plug

supplied.

Two

wire

shielded

cable

is

recommended

for

this

connection.

If

the

required

length

is

more

than

a

few

feet,

the

shunt

capacitance

effect

should

be

considered

to

avoid

possible

high

frequency

line

losses.

When

connecting

shields,

it

is

usually

desirable

to

connect

to

chassis

ground

on

one

end

only

to

avoid

possible

hum

loops

between

the

cartridge

equipment

and

the

connected

console

or

amplifier.

11.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

3.6

3.7

The

Connecting

diagram

is

as

follows:

(

+)

GJ

GJ

(

+)

L.

Channel

(-)

G G

(-)

(Mono)

(G)

G

Q]

(G)

REMOTE

CONTROL

CONNECTIONS

R.

Channel

(Stereo)

The

12

pin

remote

control

connectors~2

fort~

top

_

deck

and

J22

for

the

bottom

deck

are

factory

connected

for

the

lb

normally

required

outputs.

The

typical

remote

control

connections

are

as

indicated

in

the

pin

diagram

below.

TER

LOAD

(Sources)

OPERATOR

PERIODIC

MAINTENANCE

LOAD

I

I

L:i:•NG

OUT

The

operator

is

often

charged

with,

or

may

find

it

necessary

to

perform

periodic

cleaning

maintenance

and

other

inspection

to

insure

proper

operation

of

tape

cartridge

machines.

These

maintenance

routines

may

be

daily

or

weekly

depending

upon

the

amount

of

use.

12.

www.SteamPoweredRadio.Com

These

typical

maintenance

functions

are

as

follows:

CLEAN

HEADS, PRESSURE ROLLER

and

CAPSTAN SURFACES-

These

cleaning

functions

are

quality

is

to

be

achieved.

frequency

losses

in

replay

very

important

if

good

Dirt

on

heads

can

cause

or

recording

due

to

tape

air

high

spacing

from

the

head

gaps

and,

under

worst

cases

cause

total

loss

of

audio

or

the

cue

functions.

Lubricant

build

up

on

the

pressure

roller

surface

or

the

capstan

surface

seriously

degrades

pulling

capability

due

to

loss

of

contact

friction

on

these

driving

surfaces

and

under

worst

cases

will

cause

serious

"wow"

or

slip

of

the

tape.

Clean

these

surfaces

with

denatured

alcohol

or

isopropol

alcohol

solvents,

readily

available

at

most

hardware

stores,

by

saturating

and

wringing

dry

a

soft

cloth

or

swab

to

avoid

dripping

of

solvent

into

the

motor

bearing,

etc.

Do

not

use

solvents

such

a

Xyolene

or

Kerosene

since

these

seriously

degrade

rubber

parts.

INSPECT CARTRIDGE

and

TAPE FOR PROPER

OPERATION-These

inspections,

especially

before

re-recording

can

save

the

failure

later

on.

Do

not

attempt

to

record

tape

which

is

slick

on

either

the

oxide

or

the

lubricant

(rear)

surface.

Slick

oxide

surface

usually

means

that

much

of

the

oxid

e

is

missing

and

proper

recorded

levels

cannot

be

achieved

without

serious

distortion

and

loss

of

high

frequency

material.

The

cue

tones

especially

will

usually

be

weak

and

may

not

function

properly.

Loss

of

lubricant

means

that

pulling

tension

has

seriously

increased

and

will

soon

cause

"slip"

in

the

playing

sound.

It

is

almost

certain

that

short

life

will

be

experienced

before

breakage

of

the

tape

occurs.

Proper

operation

of

cartridges

are

normally

detected

during

daily

use.

The

careful

operator

may

observe

potential

recurring

failures

and

avoid

their

occurance.

Periodic

audio

drop-out

for

instance

may

relate

to

a

badly

deformed

pressure

pad

or

increasing

tension

which

may

overcome

the

pressure

pad

conformity.

Erroneous

cues

can

indicate

"pops"

on

the

cue

channel

which

cause

false

tripping

or

stop

of

the

drive

system.

Failures

of

these

types

should

result

in

setting

aside

the

cartridge

for

further

off

air

testing

to

determine

if

they

should

be

used

or,

if

machine

maintenance

is

required.

13.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

4,0

CIRCUIT

DESCRIPTIONS

4.1

POWER

SUPPLY

AND

SWITCHING CIRCUITS

CARD

4.2

The

D.C.

pow

er

supplies,

solenoid

switching

circuits

and

the

motor

switching

circuit

are

located

on

the

plug-in

circuit

card

151-69.

Refer

to

the

schematic

in

Section

9.

Diodes

Dl

and

D2

provide

rectified

DC

from

the

center

tapped

winding

of

the

power

transformer

to

capacitor

Cl

for

smoothing.

This

approximately

33

volts

DC

is

fed

to

edge

connection

pin

18

and,

to

the

input

of

the

24

volt

regulator

Ul

for

further

filtering

and

use

in

the

machine

control

circuits.

It

is

also

fed

thru

diodes

D3

and

D4

and

resistors

Rl

and

R2

to

the

solenoid

switching

circuits

explained

later.

Diodes

D6

and

D7

in

a

similar

manner

supply

approximately

18

volts

DC

to

the

input

of

the

12

volt

regulator

U2.

This

regulated

and

filtered

12

volts

DC

is

used

for

the

audio

and

logic

control

circuits.

Transistor

Ql

is

a

power

switch

for

the

solenoid

of

the

upper

deck.

Capacitor

CS

is

charged

to

the

33

volts

DC

supply

when

the

machine

is

idle

and

serves

as

a

"boost"

voltage

source

to

accelerate

the

solenoid

when

Ql

is

first

turned

on

by

the

logic

driver.

Diodes

Dl3

and

Dl5

serve

as

transient

suppressors

for

the

solenoid

inductance

and

diode

Dl4

acts

as

an

isolation

diode

for

the

Run

Lamps.

The

circuits

for

the

lower

deck

is

identical

and

are

provided

by

transistor

Q2

and

the

associated

parts.

Integrated

circuit

U3

(light

activated

SCR)

along

with

diodes

D9

thru

Dl2

serve

as

an

isolated

AC

switch

to

turn

the

capstan

motor

on

or

off

from

the

logic

signal

"MOTOR=0".

Diodes

DS

and

D8

protect

their

respective

voltage

regulators

from

accidental

reverse

voltage

failure.

TWIN

DECK

LOGIC

CIRCUITS

CARD

The

logic

to

control

playing

functions

of

both

decks

are

located

on

the

plug

in

circuit

card

151-68.

Refer

to

the

schematic

in

Section

9.

14

.

www.SteamPoweredRadio.Com

The

schematic

is

formatted

such

that

most

input

signals

are

shown

on

the

left

side

with

output

decision

signals

exiting

on

the

right

side.

Internal

word

statements

define

some

of

the

major

signal

paths

for

assistance

in

understanding.

The

logic

1

state

is

at

or

near

+12DC

volts

and

logic

0

state

is

at

or

near

chassis

ground

potential.

Two

identical

sections

of

logic

are

contained

on

this

card

for

the

most

common

functions,

while

one

output,

Motor=0

is

derived

in

OR

format.

This

purpose

will

be

described

later.

Integrated

circuits

Ul,

U2

and

U3

are

exclusive

to

Deck

#1

(the

upper

deck),

while

U6,

U7

and

UB

are

their

counterparts

exclusive

to

Deck

#2.

One

half

of

US

and

U9

as

well

as

sections

of

U4

are

common

to

both

decks.

The

following

description

will

be

of

Deck

#1

circuits

only

and

is

the

same

functionally

except

for

part

numbers

in

the

case

of

Deck

2

circuits.

Integrated

circuit

U2

is

a

two

section

SET-RESET

latch.

Section

2

is

the

START-STOP

latch,

while

section

1

is

the

Replay

Reminder

latch.

Section

3

of

Ul

is

the

steering

section

for

the

START

signal.

When

Ready=0

and

Start=0

are

present,

pin

10

is

at

logic

1,

setting

the

RUN

latch

to

ON.

Pin

13

of

Ul

produces

a

RUN=

J.

logic

for

use

in

the

cue

and

program

control

circuits,

while

pin

12

thru

section

4

of

Ul

and

transistor

Ql

produces

the

RUN

DRIVE

signal

used

in

the

solenoid

switching

circuit.

U3

integrates

the

three

signals

STOP

(P.B.),

CUE=l

and

CART.

SW

(in=l)

for

decision

of

the

rest

of

the

circuits.

When

the

CART

SW.

is

at

logic

1

and

INHIBIT=l

(not

inhibited),

either

CUE=l

or

STOP

P.B.=0

causes

U3

pin

6

to

produce

a

stop=l

signal

to

reset

U2.

When

CUE=l,

pin

9

of

U3

causes

the

REPLAY

REMINDER

latch,

pin

6

to

turn

on,

creating

the

PLAYED=l

signal

and

turning

on

the

PLAYED

light

via

transistor

Q2.

In

the

lower

deck

(#2)

the

PLAYED

light

is

via

section

1

of

Ul0.

15.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

The

PLAYED=l

signal

is

coupled

via

switch

1

section

D

to

pin

1

of

Ul.

This

signal

produces

an

output

logic

1

at

pin

3,

removing

the

READY=O

signal.

In

a

similar

manner,

if

a

cartridge

is

not

in

place

(CART

SW=O),

pin

8

of

U4

turns

off

the

READY=O

via

pin

2

of

Ul.

The

REPLAY

REMINDER

latch,

U2

pin

4

is

reset

each

time

the

cartridge

is

removed

or,

if

the

link

between

pin

5

and

pins

11

and

12

of

U3

is

in

place,

this

reset

occurs

by

the

STOP

pushbutton.

Pin

10

of

Section

2,

US

sees

the

RUN=l

signal

each

time

the

machine

is

started.

This

action

triggers

the

output

at

pin

12

of

US

to

INHIBIT=O.

The

duration

of

this

inhibit

is

determined

by

C9

and

R21

and

is

factory

set

at

approximately

1.75

seconds.

Integrated

circuit

U9

pin

1

and

pin

2

are

connected

to

the

logic

of

each

deck.

These

signals

are

identified

as

MOTOR

l=l

and

MOTOR

2=1.

If

either

deck

remains

in

the

READY

state

the

output

of

U9

pin

3

is

at

MOTOR=O,

turning

the

motor

on.

If

both

READY

states

are

missing

such

as

the

cartridges

out

or

both

decks

are

PLAYED,

the

motor

is

turned

off

to

conserve

power

and

heat.

If

it

is

required

that

the

motor

run

continuously,

replace

diode

D7

with

a

link

of

wire.

4.3

PROGRAM

AMPLIFIER(S)

and

CUE

CIRCUITS

CARD

The

program

and

cue

circuits

are

both

contained

on

a

single

circuit

card

151-67.

There

are

two

identical

cards,

one

for

each

associated

deck.

The

card

located

on

the

extreme

L.

side

is

for

the

top

deck

(Deck

#1)

while

the

second

card

from

the

L.

side

is

for

the

lower

deck

(Deck

#2).

Refer

to

the

schematic

in

Section

9.

PROGRAM

AMPLIFIER(S)

SECTION-

The

play

head(s)

are

connected

via

cables

and

3

pin

connectors

on

the

rear

of

the

card

nearest

the

deck

plate.

Stereo

models

have

2

connectors

in

this

location.

The

top

connector

is

L.

channel

and

the

bottom

is

R.

channel.

Observe

the

identification

dots

on

the

cable

when

plugging

in

these

cables

to

avoid

interchange

of

the

channels.

I.C.

Ul

is

a

low

noise

packaged

pre-amplifier

with

approximately

40dB

of

mid

range

gain.

Two

frequency

equalizers

are

provided

in

the

gain

loops.

For

L.

Channel

of

stereo

or

mono

models,

R8

is

the

adjustable

low

frequency

equalizer

of

limited

range

in

th

e

inverting

feedback

section.

CS

sets

the

crossover

frequency

for

16.

www.SteamPoweredRadio.Com

RB,

which

is

adjusted

typically

at

S0Hz

to

improve

the

low

frequency

loss

and

contour

effect

of

the

head

used.

The

base

gain

is

established

by

RS

and

C4

while

the

equalized

portion

is

set

by

R7.

Capacitor

C6

bypasses

the

mid

to

high

frequencies.

R2

is

the

adjustable

portion

of

the

high

frequency

shunt

equalizer,

while

C2

and

R3

establishes

the

crossover

frequency

of

the

equalizer.

Resistor

R4

establishes

the

DC

feedback

bia

s

in

conjunction

with

R6.

Level

control

R9

allows

for

output

level

adjustment.

I.C.

U2

is

a 4

section

FET

analog

control

switch

to

control

turn

off

of

the

audio

during

non-running

periods.

Resistor

R36,

R37

and

R3B

and

Capacitor

Cl6

provide

a

ramp-up

and

ramp-down

time

to

avoid

audio

pops

.

Transistor

Ql

is

a

split

phase

pre-driver

for

the

complimentary

output

amplifier

Q2

and

Q3.

The

output

is

coupled

thru

Cl9

to

the

primary

of

the

line

transformer

located

on

the

Output

Circuit

card.

The

R.

Channel

of

stereo

models

is

identical

to

the

description

of

the

L.

Channel

above

except

for

the

change

in

part

number

designations.

CUE

AMPLIFIER

AND

DETECTORS

The

cue

head

is

connected

via

a 3

pin

connecting

cable

located

on

the

rear

of

the

circuit

card.

Intergrated

circuit

U3

is

configured

in

a

two

stage

equalized

pre-amplifier

with

output

essentially

constant

for

the

3

NAB

cue

tone

flux

levels.

This

output

is

connected

thru

R49

and

C2B

to

section

2

of

I.C.

U4

which

acts

as

the

isolation

amplifier

for

logging

signal

outputs,

used

frequently

in

automation

and

accessory

controllers.

This

output

is

routed

to

pin

10

of

the

remote

sockets

and

is

often

valuable

for

cue

track

monitoring

and

test

functions.

Section

1

of

I.C.

U4

is

configured

as

a

bridged

T

passive

amplifier

tuned

to

the

1

kHz

center

frequency.

This

circuit

is

stable

and

will

require

no

further

tuning.

The

output

is

connected

via

C33

to

transistor

Q7.

This

is

a

zero

bias

A.C.

detector

coupled

thru

R61

to

C34.

These

components

along

with

R60

form

a

time

constant

to

delay

turn

on

of

QB

for

approximately

20

milli-seconds

to

immunize

the

circuit

from

short

transients

and

remove

"clatter".

QB

derives

the

logic

signal

CUE=l

for

automatic

stop

control.

17.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

This manual suits for next models

2

Table of contents