Austro Engine AE50R Instruction manual

ENGINE MANUAL

Operation / Maintenance / Installation

AE50R

AE50RA

AE50RAB

Doc. No. : E1.01.01 – E

Revision : 6

Date of Revision : 10 March 2011

The technical information contained in this document has been approved under the

authority of DOA No. EASA.21J.399 in conjunction with the Mandatory Design

Change MDC E1 - 116.

Affected Pages: Chapter Page

all all

Instruction:

- Replace the affected pages of the original manual with the

pages contained in this revision.

Austro Engine GmbH

Rudolf - Diesel – Straße 11

A – 2700 Wiener Neustadt

Austria

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page1-1

FOREWORD

We congratulate you on the acquisition of your new Austro Engine AE50R.

Skillful operation of the engine increases both safety and the enjoyment of flying. Please take

the time therefore, to familiarize yourself with your new AE50R.

This engine may only be operated in accordance with the procedures and operating limitations

of the Engine Manual.

This document is protected by copyright. All associated rights, in particular those of

translation, reprinting, radio transmission, reproduction by photo-mechanical or similar means

and storing in data processing facilities, in whole or part, are reserved.

Austro Engine is a part of Diamond Aircraft Industries GmbH.

Copyright © by: AUSTRO ENGINE GmbH

Rudolf-Diesel – Strasse 11

A – 2700 Wiener Neustadt

Austria

Phone : +43 – 2622 – 23000

Fax : +43 – 2622 – 23000 - 2711

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page1-2

1.1 Record of Revisions

All revisions of this manual, with the exception of -

Temporary Revisions

must be recorded in the following table. Revisions of approved chapters require the

countersignature of Austro Control GmbH.

The new or amended text is indicated by a vertical black line at the right hand side of the

revised page, with the revision number and data appearing at the bottom of the page.

If pages are revised which contain information valid for your particular serial number

(modification level of the engine, Equipment Inventory, etc.), then this information must be

transferred to the new pages in hand–writing.

Temporary revisions, if applicable, are inserted behind the cover page of this manual.

Temporary revisions are used to provide information on systems or equipment until the next

‘permanent’ revision of the Engine Manual. When a ‘permanent’ revision covers a Mandatory

or Optional Design Change (MDC or ODC), then the corresponding temporary revision is

superseded.

It is the responsibility of the operator to ensure that this manual is maintained to a current

status.

If you move, or the ownership of the engine/aircraft changes, please complete the change of

address card and send it to Austro Engine GmbH.

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 1-3

Rev.

No. Reason Chapter Page(s) Date of

Revision Approval Date of

Approval Date In-

serted Signature

5

5.2.3 6

Editorial

changes 5.2.4 6

- -

1

Part No

Correction 11.1 26

15-02-06

- -

Page

numbering all all

1.2 1-4

8.1.5 8-1

8.5.4 8-3

9.4 9-3

9.5.

9.5.1

9.5.2

9-4

9.5.3 9-5

13.5.5 13-5

14-1

14.1 14-2

18.7.1 18-12

18.8.1 18-15

Editorial

Changes

18.8.2 18-16

2

Maintenance

Interval 12.1 12-1

10-04-06

1.1 1-3

1.2 1-4

3

New spark

plug

implemented 11.1 11-1

22-11-06

4 No. changed

1.1

1.2

8.3

11.1

1.3

1-4

8-1

11-1

10-11-08

5 Editorial

change

1.1

1.2

8.3

9.4

11.1

1-3

1-4

8-1

9-3

11-1

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 1-4

6

All Diamond

Logos

changed to

Austro

Engine

Logo.

Oil

specification

changed

all all 10-03-11

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 1-5

1.2 LIST OF EFFECTIVE PAGES

Ch. Page Date

1-1 10-March-2011

1-2 10-March-2011

1-3 10-March-2011

1-4 10-March-2011

1-5 10-March-2011

1

1-6

1-7 10-March-2011

10-March-2011

2 2-1 10-March-2011

3-1 10-March-2011

3 3-2 10-March-2011

4 4-1 10-March-2011

5-1 10-March-2011

5-2 10-March-2011

5 5-3 10-March-2011

6-1 10-March-2011

6-2 10-March-2011

6 6-3 10-March-2011

7-1 10-March-2011

7 7-2 10-March-2011

8-1 10-March-2011

8-2 10-March-2011

8 8-3 10-March-2011

8-4 10-March-2011

9-1 10-March-2011

9-2 10-March-2011

9-3 10-March-2011

9-4 10-March-2011

9

9-5 10-March-2011

10 10-1 10-March-2011

11-1 10-March-2011

11 11-2 10-March-2011

12-1 10-March-2011

12-2 10-March-2011

12 12-3 10-March-2011

13-1 10-March-2011

13-2 10-March-2011

13-3 10-March-2011

13-4 10-March-2011

13

13-5 10-March-2011

14-1 10-March-2011

14 14-2 10-March-2011

15-1 10-March-2011

15 15-2 10-March-2011

16 16-1

10-March-2011

Ch. Page Date

17-1 10-March-2011

17 17-2 10-March-2011

18-1 10-March-2011

18-2 10-March-2011

18-3 10-March-2011

18-4 10-March-2011

18-5 10-March-2011

18-6 10-March-2011

18-7 10-March-2011

18-8 10-March-2011

18-9 10-March-2011

18-10 10-March-2011

18-11 10-March-2011

18-12 10-March-2011

18-13 10-March-2011

18-14 10-March-2011

18-15 10-March-2011

18-16 10-March-2011

18-17 10-March-2011

18

18-18 10-March-2011

19-1 10-March-2011

19-2 10-March-2011

19 19-3 10-March-2011

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 1-6

1.3 TABLE OF CONTENTS

Chapter

INTRODUCTION

(a non-approved chapter)..........................................................................................................1

PREFACE

(a non-approved chapter)..........................................................................................................2

SAFETY INFORMATION

(a non-approved chapter)..........................................................................................................3

(RESERVED)

(a non-approved chapter)..........................................................................................................4

GENERAL ENGINE DATA

(a non-approved chapter)..........................................................................................................5

OPERATING DATA / LIMITATIONS

(an approved chapter)...............................................................................................................6

COMPONENTS

(a non-approved chapter)..........................................................................................................7

DECRIPTIONS OF SYSTEMS

(a non-approved chapter)..........................................................................................................8

OPERATING THE ENGINE

(a non-approved chapter)..........................................................................................................9

ENGINE EMERGENCY PROCEDURES

(a non-approved chapter)........................................................................................................10

MAINTENANCE NOTES

(a non-approved chapter)........................................................................................................11

SCHEDULED MAINTENANCE

(a non-approved chapter)........................................................................................................12

COOLING SYSTEM

(a non-approved chapter)........................................................................................................13

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 1-7

ENGINE INTERNAL INSPECTION

(a non-approved chapter)........................................................................................................14

GROUND RUN

(a non-approved chapter)........................................................................................................15

MAINTENANCE AND OVERHAUL

(a non-approved chapter)........................................................................................................16

TROUBLE SHOOTING

(a non-approved chapter)........................................................................................................17

NOTES FOR INSTALLERS OF ENGINES

(a non-approved chapter)........................................................................................................18

FORM SHEETS

(a non-approved chapter)........................................................................................................19

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 2-1

2.0 PREFACE

Every reasonable effort has been made to ensure that the information contained in this

publication is correct when going to print.

However, as Austro Engine GmbH policy is one of continuous improvement, the information

given here may be superseded over a period of time by manual revisions or temporary by

Service Bulletins.

THIS MANUAL IS PUBLISHED BY:

Austro Engine GmbH

Rudolf – Diesel - Straße 11

A – 2700 Wiener Neustadt

Tel.: +43 (0) 2622 – 23000

Fax.: +43 (0) 2622 – 23000 - 2711

Internet: www.austroengine.at

This manual is for use with engines specified by Engine Type Certificate Data Sheet No

EASA.E.085.

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 3-1

3.0 SAFETY INFORMATION

The instructions in this manual have been compiled to assist pilots and personnel responsible

for maintenance in the correct operation of the engines produced by Austro Engine GmbH.

Only correct operation and maintenance can ensure optimum availability throughout engine

life.

No recommendation in this manual absolves operators from compliance with any official

directive that may be issued by the controlling aviation authority of any country concerned, or

with any relevant Austro Engine GmbH Service Bulletins.

Austro Engine personnel are always happy to answer queries or give advice on individual

service problems. All queries to Austro Engine GmbH should be accompanied by details of the

engine model and serial number, hours operated and any other relevant information.

3.1 Safety Symbols

NOTE !

A note symbol shows an additional significant information.

CAUTION!

A caution symbol indicates special procedures which should be

followed to avoid the risk of serious damage to engine or to

components.

WARNING!

A warning symbol indicates special procedures, which must be

followed to avoid the risk of death or serious injury to persons.

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 3-2

3.2 Model Designation Breakdown

3.3

NOTE!

It is strongly recommended that only genuine, quality–assured,

replacement spare parts are used when carrying out

maintenance operations on this engine.

The use of parts not approved by Austro Engine GmbH may

significantly affect the performance, reliability and life of the

engine and may hazard the operator.

WARNING!

The use of parts not approved by Austro Engine GmbH may

invalidate the Engine Certification.

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 4-1

4.0 Reserved

Intentionally left blank

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 5-1

5.0 GENERAL ENGINE DATA

5.1 Description

Wankel type rotary, single rotor, dual spark ignition, liquid cooled rotor housing, forced air

cooled rotor, normal aspirated.

5.2. Technical data

5.2.1 Design Responsibility

Austro Engine GmbH

Rudolf – Diesel – Straße 11

A – 2700 Wiener Neustadt

Austria

5.2.2 Certification

Certification Basis: JAR – 22, Subpart H, at Change 4 effective 12/12/85 together with Orange

Paper amendment 22/01/90.

5.2.3 Engine Particulars

Design Single rotor Wankel–type rotary engine

Eccentricity 11.6 mm

Width of Housing 68.2 mm

Generating Radius 69.0 mm

Compression Ratio 9 : 1

Swept Volume 294 ccm

Rotor Cast iron internally cooled by a belt driven centrifugal

fan.

Main and End Housing Aluminium alloy castings, cooled with a pump

circulated pressurized water–glycol mixture and

supporting an optional oil separator assembly

(supplied by the installer mounted directly onto the

outlet casting).

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 5-2

Eccentric Shaft Hardened and ground alloy steel. The complete

rotating assembly is in full dynamic balance to

minimise vibration, achieved by counter weighting

each end of the assembly. Both the main and rotor

bearings are rolling element types.

Flywheel Cast iron fitted with an induction–hardened steel

starter ring gear.

5.2.4 Out–put Drive

Take from the eccentric shaft via a woodruff key.

Rotation Direction The eccentric shaft rotate in a clockwise direction

when viewed from the driving side of the engine.

5.2.5 Net Dry Weight

Approximately 26,8 kg. (59,1 lbs)

5.2.6 Cooling

Approximately 90% of surplus heat is rejected into the

liquid cooling system; the balance is rejected via rotor

cooling air.

Coolant 50 : 50 Distilled Water – Ethylene Glycol mix

Silkolene PRO–COOL (or equivalent)

5.2.7 Fuel Specification

AVGAS 100LL

EUROSUPER, ROZ 95, in accordance with EN228

or equivalents.

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 5-3

5.2.8 Pressure to Carburettor

min 0.276 bar (4 psi)

max 0.414 bar (6 psi)

5.2.9 Lubrication

Lubrication of all bearings and rubbing surfaces is

achieved via two lines from the oil metering unit driven

off the water pump. The flow rate of the metering unit

is calibrated and must not be adjusted. Use only

approved engines oils.

Oil Separator An optional oil separator is recommended. The

separator is to be supplied by the engine installer.

5.2.10 Oil Specification

Silkolene Comp 2 Premix (Not comp 2 Injector)

Castrol XR77 (EMPA specification 417478/01)

Castrol Power 1 Racing 2T (API TC+, JASO FD, ISO EGD)

AeroShell Oil Sport Plus2 (API TC)

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 6-1

6.0 OPERATING DATA / LIMITATIONS:

Static sea level ratings under the following conditions:

- International Standard Atmospheric conditions at seal level

- Generator functioning

- Liquid coolant outlet temperature 65 °C (± 5 °C)

- Standard induction pipe fitted with filter

- Power measured at eccentric shaft output

- Approved fuels

- Test bed exhaust used

6.1 Maximum Take – off Rating

Max. T/O – Power (minimum) 36.5. kW (49 BHP)

(Value quoted includes losses associated

with intake exhaust conditions specified.)

Max. T/O – RPM 7 500 RPM

Fuel consumption (max) 19 - 21 liters / hr

Exhaust back pressure 0.21 bar ± 0.04 bar (3 psi ± 0.5 psi)

at 7500 RPM with test bed system

6.2 Maximum Continuous Rating

Max. Cont. Power 34.3 kW (46 BHP)

Max. Cont. RPM 6,900 RPM

Fuel consumption (max) 12 - 15 liters / hr

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 6-2

6.2.1 Power Curve

6.3 Operating Limitations

6.3.1 Engine RPM

Maximum for take–off (for 3 mins) 7 500 RPM

Maximum Continuous 6 900 RPM

Maximum Overspeed (20 sec. limit) 7 800 RPM

Idle Minimum 1 750 RPM

6.3.2 Ambient Temperature Limits

Minimum Starting Ambient (without priming) -10 °C

Maximum Ambient +55 °C

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 6-3

6.3.3 Liquid Coolant Temperature Limits

Maximum for Take–off 90 °C

Minimum for Take–off 60 °C

Maximum continuous 100 °C

6.3.4 Rotor Cooling Air Outlet Temperature Limits

Maximum for Take–off (3 minutes) 120 °C

Maximum Continuous 110 °C

6.3.5 Exhaust Gas Temperature (EGT)

Maximum Exhaust Gas Temperature 950 °C

6.3.6 Fuel Pressure

min 0.276 bar (4 psi)

max 0.414 bar (6 psi)

6.3.7 Altitude

The engine has been tested for use up to 14.000 ft pressure altitude

6.4 Manuals

Operation / Maintenance / Installation Doc. No. E1.01.01–E

Overhaul Manual Doc. No. E1.04.01–E

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 7-1

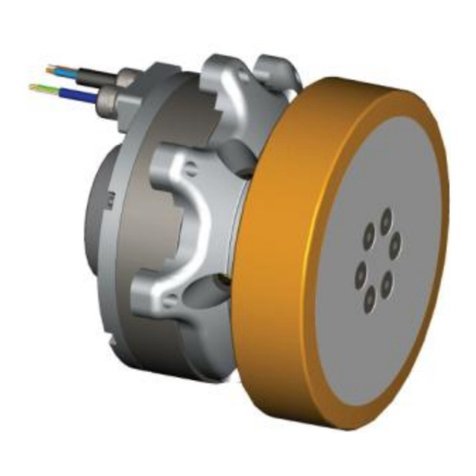

7.0 COMPONENTS

Location of Components

AE50R, AE50RA

AE50RAB Engine Manual

Doc. No. E1.01.01-E Rev. 6 10-March-2011 Page 7-2

7.1 Description of Components

7.1.1 Rear Assemblies

These assemblies comprise of a back plate, with integral mounting lugs, water pump,

alternator, speed sensors, rotor cooling air fan assembly, oil pump and starter motor.

7.1.2 Front Assemblies

The front assemblies comprise of a water cooled end plate, temperature transmitter.

7.1.3 Center and Rotating Assembly

The center assembly comprises a rotor housing with passageways for liquid cooling.

Externally is the throttle body with fuel injector, spark plugs, and exhaust flange and, internally,

the eccentric shaft and rotor assembly.

7.1.4 Rotor Sealing

Rotor sealing is provided by the tip seals, side seals and corner seals with each seal being

spring loaded outwards. The corner seals placed at the junction of the side and tip seals

provide sealing at these critical locations.

This manual suits for next models

2

Table of contents

Other Austro Engine Engine manuals

Popular Engine manuals by other brands

Siemens

Siemens SIMOTICS FD 1LM1 operating instructions

Nice

Nice Era Track Edge Instructions and warnings for use

Perkins

Perkins 854F-E34T Troubleshooting

ModelCraft

ModelCraft 23 77 41 operating instructions

Stellar Lighting

Stellar Lighting MK-45 RGB user manual

Hyundai

Hyundai L500 SERIES Installation and operation manual

DLE

DLE DLE60 user manual

Mercury

Mercury SKI user manual

SelectBlinds

SelectBlinds Roller Shade Deluxe Spring Motor manual

DLA

DLA DLA56 user manual

RADEMACHER

RADEMACHER RolloTube CLIS Translation of the Original Operating and Assembly Manual

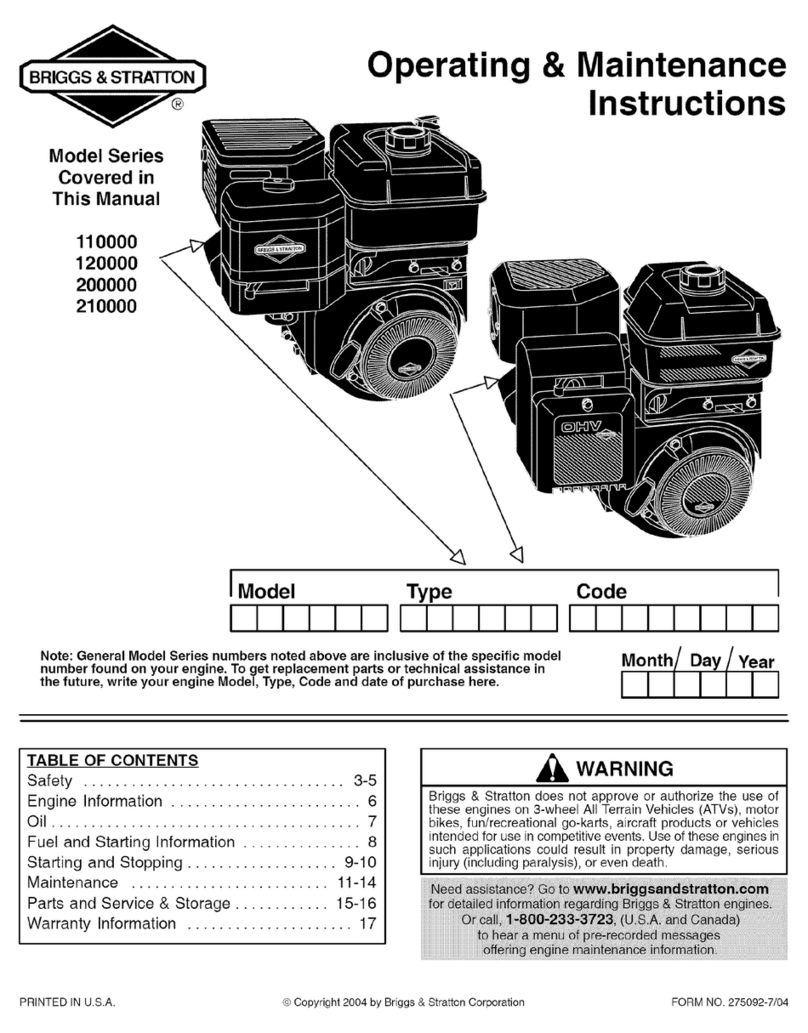

Briggs & Stratton

Briggs & Stratton PROFESSIONAL SERIES 110000 operating & maintenance manual