Austro Engine E4P User manual

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: Intro 1

Revision no: 1

–Intentionally left blank –

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: Intro 2

Revision no: 1

Date: Wiener Neustadt, 15.Nov.2016

Author: Austro Engine GmbH

Rudolf –Diesel –Straße –11

A-2700 Wiener Neustadt

Document number: E4.01.02

Revision: 1

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: Intro 3

Revision no: 1

–Intentionally left blank –

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 0-1

Revision no: 1

0Index

0Index ................................................................................................... 0-1

1Identification ....................................................................................... 1-1

1.1 Type Designation..........................................................................................1-1

1.2 Engine Identification.....................................................................................1-1

1.3Record of Revision........................................................................................1-2

1.3.1 List of Revision ................................................................................................... 1-3

1.3.2 List of incorporated Temporary Revisions ............................................................. 1-4

1.4 Design Holder ..............................................................................................1-5

1.5 Manufacturer ...............................................................................................1-5

1.6 List of Abbreviations .....................................................................................1-6

2General Information............................................................................ 2-1

2.1 Description and Using ...................................................................................2-1

2.2 Safety..........................................................................................................2-2

2.3 Safety Information........................................................................................2-2

2.4 Dimension and Volume .................................................................................2-3

2.5 Technical Data Sheet for E4P Engine..............................................................2-4

2.5.1 Engine Performance............................................................................................ 2-4

2.5.2 High power performance..................................................................................... 2-5

2.5.3 Fuel consumption ............................................................................................... 2-6

2.5.4 Propeller Setpoint Curve...................................................................................... 2-6

2.5.5 Engine and Gearbox Data Sheet .......................................................................... 2-7

2.5.6 Limitation Section ............................................................................................... 2-8

2.5.6.1 Oil .............................................................................................................. 2-8

2.5.6.2 Coolant ....................................................................................................... 2-9

2.5.6.3 Fuel ...........................................................................................................2-10

2.5.6.4 Fuel Grade .................................................................................................2-10

2.5.6.5 Speed ........................................................................................................2-11

2.5.6.6 Voltage ......................................................................................................2-11

2.5.6.7 Performance...............................................................................................2-11

2.5.7 Information Section ...........................................................................................2-12

2.5.7.1 Engine Oil ..................................................................................................2-12

2.5.7.2 Coolant ......................................................................................................2-12

2.5.7.3 Fuel ...........................................................................................................2-12

2.5.8 Operating Envelope ...........................................................................................2-13

3Delivery, Storage and Standstill Period .............................................. 3-1

3.1 Delivery .......................................................................................................3-1

3.2 Storage up to 6 months ................................................................................3-1

3.3 Storage over 6 months..................................................................................3-1

3.4 Engine depreservation ..................................................................................3-1

3.5Standstill Period ...........................................................................................3-2

4Operating Instructions ........................................................................ 4-1

4.1 Engine Start Procedure .................................................................................4-1

4.1.1 Pre-Start Inspection ............................................................................................ 4-1

4.1.2 Engine Start ....................................................................................................... 4-2

4.1.3 Warm Up ........................................................................................................... 4-2

4.1.4 Before Take-off Check......................................................................................... 4-3

4.1.5 During Flight Check ............................................................................................ 4-3

4.1.6 Engine OFF ........................................................................................................ 4-3

4.2 Low Oil Pressure...........................................................................................4-3

4.3 Restart in flight ............................................................................................4-4

4.3.1 Restart of engine by starter................................................................................. 4-4

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 0-2

Revision no: 1

5Emergency Procedures ........................................................................ 5-1

5.1 Power loss and abnormal engine behaviour ....................................................5-1

5.2 Low Oil Pressure...........................................................................................5-1

5.3 High Oil Temperature....................................................................................5-1

5.4 High Gearbox Oil Temperature.......................................................................5-1

5.5 Low fuel pressure .........................................................................................5-2

5.6 High Fuel Temperature .................................................................................5-2

5.7 High Coolant Temperature ............................................................................5-2

5.8 Engine Fire ..................................................................................................5-2

5.9 Electric power supply out of range .................................................................5-2

5.9.1 Restart of engine by windmilling .......................................................................... 5-2

6System Description.............................................................................. 6-1

6.1 Intake System..............................................................................................6-1

6.2 Exhaust System............................................................................................6-1

6.3 Fuel System .................................................................................................6-2

6.4 Coolant System ............................................................................................6-3

6.4.1 Standard Coolant System .................................................................................... 6-3

6.4.2 Coolant System with optional Gearbox Oil Cooler .................................................. 6-4

6.5 Lubricating System .......................................................................................6-5

6.6 Electrical System ..........................................................................................6-6

6.6.1 EECU Functions .................................................................................................. 6-8

6.6.2 Engine Speed and Power Regulation ...................................................................6-12

6.6.3 Error Handling ...................................................................................................6-14

6.6.3.1 Description of ECU Switch Over ...................................................................6-14

6.6.3.2 Resetting ECU caution in Operation .............................................................6-15

6.6.3.3 Caution Handling Table Software VC33_0_05_18_pre1 .................................6-16

7Additional Information ........................................................................ 7-1

7.1 Propeller Self Test (Automatic Run-Up Test) ...................................................7-1

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 1-1

Revision no: 1

1Identification

1.1 Type Designation

TC-Designation: E4

Model: E4P(Sales Name AE330)

For detailed information about available configurations refer to latest revision of Austro Engine Service

Bulletin MSB E4-002.

If not otherwise stated this manual is applicable to all available configurations.

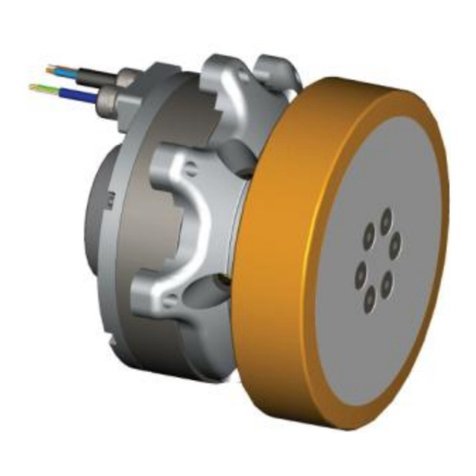

1.2 Engine Identification

Relevant data for engine identification including the serial number is stated on an engine identification

plate, which is fixed onto the crankcase beneath the starter. For further questions contact Austro

Engine GmbH.

Fig. 1.1: Engine Identification plate

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 1-2

Revision no: 1

1.3 Record of Revision

All revisions of this manual are recorded in chapter “List of Revisions”.

All incorporated temporary revisions are recorded in chapter “List of incorporated Temporary Revisions”.

New or amended text is indicated by a vertical black line at the left hand side of the revised page, with

the revision number and date appearing at the bottom of the page.

Cover pages of temporary revisions are inserted in front the cover page of this manual. The other pages

of temporary revisions are inserted adjacent to or in front of the corresponding OM pages.

Temporary revisions are used to provide information on systems or equipment until the next ‘permanent’

revision of the Engine Manual.

It is the responsibility of the installer to ensure that this manual is maintained to a current status.

If the address or the ownership of the engine/aircraft changes, an address card has to be sent to Austro

Engines GmbH.

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 1-3

Revision no: 1

1.3.1 List of Revision

Re.

No.

Reason

Chapter(s)

Page(s)

Date of

Revision

Approval /

Date

0

First Release

All

All

26.Mar.2015

EASA /

26.Mar.2015

1

MDC-E4-377

All

All

15.Nov.2016

EASA /

29.Nov.2016

*) The technical content of this document is approved under the authority of DOA ref. EASA.21J.0399

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 1-4

Revision no: 1

1.3.2 List of incorporated Temporary Revisions

Temporary Revision Number

Title of Temporary Revision

Incorporated with

Manual Rev.

OM-TR-MDC-E4-217d

Engine preservation

1

OM-TR-MDC-E4-359b

EECU Software VC33_x_05_19

1

OM-TR-MDC-E4-378

TBO extension of engine components

1

OM-TR-MDC-E4-382

EECU Software VC33_x_05_20

1

OM-TR-ODC-E4-008

Gearbox Oil Cooler

1

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 1-5

Revision no: 1

1.4 Design Holder

Austro Engine GmbH

Rudolf –Diesel –Straße 11

A-2700 Wiener Neustadt

DOA No.: EASO.21J.399

1.5 Manufacturer

Austro Engine GmbH

Rudolf –Diesel –Straße 11

A-2700 Wiener Neustadt

EASA POA No.: AT.21G.0010

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 1-6

Revision no: 1

1.6 List of Abbreviations

AE

Austro Engine

BATT

Battery

CAD

Computer Aided Design

CAN

Controller Area Network

CCW

Counter-Clockwise

CPC

Connector Type

CS

Certification Specification

DOHC

Double Overhead Camshaft

EECS

Electronic Engine Control System

EECU

Electronic Engine Control Unit

ECU

Electronic Control Unit

EMI

Electromagnetic Interference

EPC

Electric Pneumatic Converter

ESD

Electrostatic Sensitive Device

FAR

Federal Aviation Regulations

GND

Ground

GPC

Glow Plug Control Unit

HIRF

High Intensity Radiated Field

HPP

High Pressure Pump

MBN

Mercedes Benz Norm

MDC

Mandatory Design Change

ODC

Optional Design Change

RPM

Revolutions Per Minute

SW

Soft Ware

TDD

Type Design Definition

TC

Turbo Charger

Ubatt

Battery Voltage

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-1

Revision no: 1

2General Information

In the present Operation Manual the proper operation of the aircraft engine E4P is documented.

With the publication of the Operation Manual Austro Engine GmbH ensures the correctness of the

instructions. In case of changes Austro Engine GmbH will inform with Service Bulletins, Service Letters

or manual amendments, if it is necessary.

In case of problems with the engine operation or any further questions about the engine,

contact Austro Engine GmbH.

The following symbols and warning signs are used in the manual to point out important instructions.

They must be heeded strictly to prevent personal injury and material damage, to insure operational

safety of the aircraft and to avoid any damage to the aircraft as a result of incorrect handling.

Warning: Disregarding these safety rules can cause personal injury or even death.

Caution: Disregarding these special instructions and safety measures can damage the

engine or other components.

Note: Additional not or instruction for better understanding of an instruction.

2.1 Description and Using

The E4P is a liquid-cooled, in-line four-stroke four cylinder engine with a double overhead camshaft

(DOHC) with four valves per cylinder. The valves are actuated by the cam follower

The direct fuel injection is realized by means of a common rail technique and the engine is charged by

a turbo charger in combination with an intercooler.

The propeller is activated by a directly integrated gearbox with an integral torsional vibration damper.

All engine components are controlled by an EECU system.

●This engine is only designed for pull propeller installations.

●The engine should not be operated without propeller.

●Only useable in aircraft.

●It is not capable for aerobatics use

●It is not allowed to run the engine without the specified quality and quantity of fluids.

●Only the use of recommended equipment and fluids grants a save run of the engine.

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-2

Revision no: 1

2.2 Safety

The required provisions of the employer’s liability insurance organization and the other relevant safety

rules, like for example the trade supervision authority have to be kept in mind.

The described work steps, contained in this Operation Manual have to be performed only by trained,

qualified persons and / or specialized companies, with a current and valid license from the aviation

authority to do such work

For further information the national aviation authority has to be contacted.

2.3 Safety Information

●To prevent personal injury and damage secure all tools before starting the engine.

●The pertinent accident prevention regulations as well as other commonly accepted safety,

occupational health and air traffic legal requirements must be observed.

●Operators must also observe any additional regulations and requirements which are applicable

in their territory.

●The engine has to be protected against contamination and potentially hazardous manipulation.

●Rotation of the propeller by hand is not recommended.

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-3

Revision no: 1

2.4 Dimension and Volume

For further information about measurements refer to the Installation Manual of the E4 series (Doc. No.:

E4.02.01).

Fig. 2.1: Engine view

Fig. 2.2: Engine view

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-4

Revision no: 1

2.5 Technical Data Sheet for E4P Engine

All speed information’s refer to the revolution speed of the propeller. The revolution speed of the engine

is declared separately.

For detailed manifold data and dimensions refer to the “Installation Manual” of the E4 engine (Doc. No.:

E4.02.01).

2.5.1 Engine Performance

Fig. 2.3: Engine Performance

Low and Idle Power Correction

Below 850 mbar ambient ECU pressure the low power output is increased and below 800

mbar ECU pressure the idle power output is increased regarding to the desired power

(power lever position) to prevent the engine from combustion extinction.

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-5

Revision no: 1

2.5.2 High power performance

Fig. 2.4: Power Curve RPM 2300

Fig. 2.5: Power Curve RPM 2200

Rated Power (100%):

132 kW

(177,0 hp)

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-6

Revision no: 1

2.5.3 Fuel consumption

Fig. 2.6: Fuel consumption

2.5.4 Propeller Setpoint Curve

Fig. 2.7: Propeller Setpoint Curve E4P

The propeller setpoint is set on the governor by the EECS on the basis of power lever position. This

propeller speed (rpm) is held at any airspeed as long as the propeller is within the range of stops.

0%

20%

90%

100%

1600

1650

1700

1750

1800

1850

1900

1950

2000

2050

2100

2150

2200

2250

2300

2350

2400

0% 20% 40% 60% 80% 100%

Propeller Speed [rpm]

Power Lever [%]

Propeller Setpoint Curve E4P

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-7

Revision no: 1

2.5.5 Engine and Gearbox Data Sheet

Max. take-off power (max. 5 min.):

132 kW

Max. continuous power:

126 kW

Max. recommended cruising power:

93,8 kW

Max. prop. Over speed:

2500 rpm

Max. take-off speed:

2300 rpm

Max. continuous speed:

2200 rpm

Max. recommended cruising speed:

2123 rpm

Idling prop speed:

710 rpm

Gearbox ratio:

I = 1.69

Operation Manual

E4P

E4.01.02

Issue date: 15.Nov.2016

Page: 2-8

Revision no: 1

2.5.6 Limitation Section

All temperature and pressure limits must not be exceeded. The limits have to be

shown to the pilot in a red range.

2.5.6.1 Oil

Oil temperature (start):

min.

-30 ºC

(-22 ºF)

Oil temperature

max.

139 ºC

(282 ºF)

Oil pressure:

at idle

min.

0,9 bar

(21.75 psi)

(at max. cont. conditions)

min.

2.5 bar

(36.26 psi)

max.

6.5 bar

(94.25 psi)

Approved engine oil types:

Brand name

SAE Grade

AUSTRO ENGINE Aero

recommended by Austro Engine GmbH

5W-40

CASTROL Edge Professional A3

5W-40

CASTROL Magnatec Professional A3

5W-40

GULF Formula GX

5W-40

LIQUI MOLY Leichtlauf High Tech

5W-40

LUKOIL Luxe synthetic

5W-40

MEGOL Motorenoel High Condition

5W-40

SHELL Helix Ultra

5W-40

VALVOLINE SynPower HST

5W-40

AEROSHELL Oil Diesel Ultra

5W-30

ADDINOL Super Power MV 0537

5W-30

BP Visco 5000

5W-30

CASTROL Edge 5W-30 A3

5W-30

CASTROL Edge Professional A3

5W-30

G-ENERGY F Synth

5W-30

GULF Formula GMX

5W-30

REPSOL Elite Common Rail

5W-30

SHELL Helix Ultra

5W-30

Table to be continued on the next page!

Table of contents

Other Austro Engine Engine manuals

Popular Engine manuals by other brands

Siemens

Siemens SIMOTICS FD 1LM1 operating instructions

Nice

Nice Era Track Edge Instructions and warnings for use

Perkins

Perkins 854F-E34T Troubleshooting

ModelCraft

ModelCraft 23 77 41 operating instructions

Stellar Lighting

Stellar Lighting MK-45 RGB user manual

Hyundai

Hyundai L500 SERIES Installation and operation manual

DLE

DLE DLE60 user manual

Mercury

Mercury SKI user manual

SelectBlinds

SelectBlinds Roller Shade Deluxe Spring Motor manual

DLA

DLA DLA56 user manual

RADEMACHER

RADEMACHER RolloTube CLIS Translation of the Original Operating and Assembly Manual

Briggs & Stratton

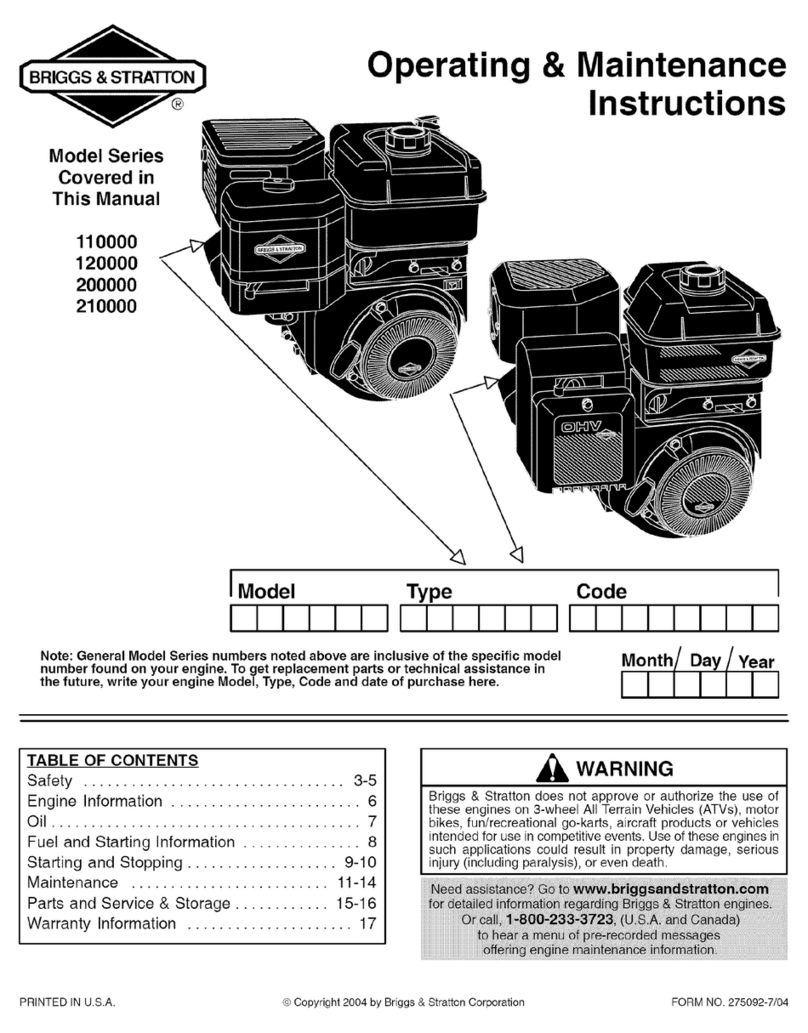

Briggs & Stratton PROFESSIONAL SERIES 110000 operating & maintenance manual